ENGLISH

INSTALLATION MANUAL

2) GENERAL INFORMATION

The THALIA control panel comes with standard factory settings. Any change

must be made using the programmer with built-in display or universal handheld

programmer.

The Control unit completely supports the EELINK protocol.

Its main features are:

- Control of 1 or 2 24V BT motors

Note: 2 motors of the same type must be used.

- Electronic torque control with obstacle detection

- Limit switch control inputs based on motor selected

- Separate inputs for safety devices

- Built-in radio receiver rolling code with transmitter cloning.

The board has a terminal strip of the removable kind to make maintenance

or replacement easier. It comes with a series of prewired jumpers to make the

installer’s job on site easier.

The jumpers concern terminals: 70-71, 70-72, 70-74. If the above-mentioned

terminals are being used, remove the relevant jumpers.

TESTING

The THALIA panel controls (checks) the start relays and safety devices (photocells)

before performing each opening and closing cycle.

If there is a malfunction, make sure that the connected devices are working

properly and check the wiring.

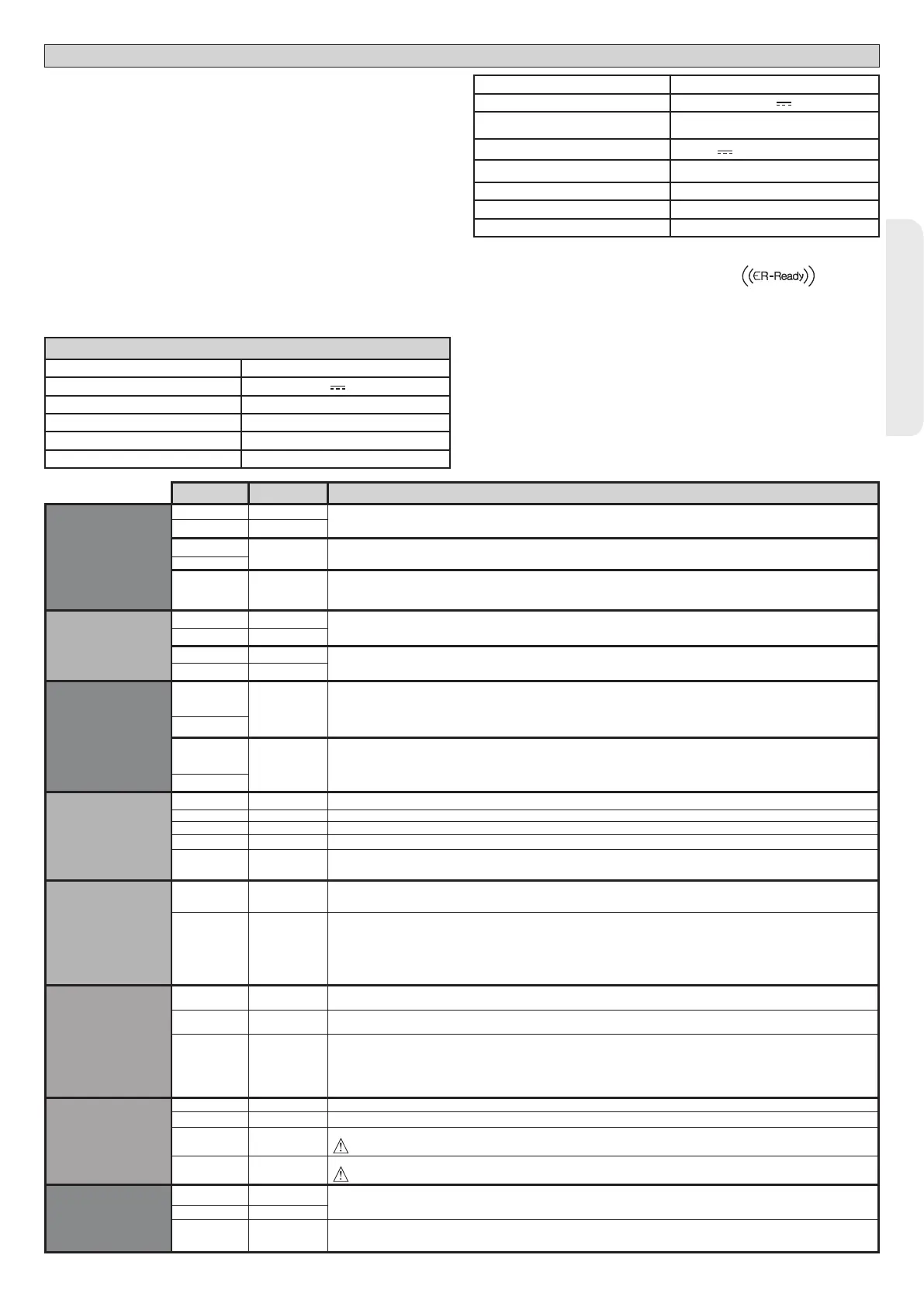

3) TECHNICAL SPECIFICATIONS

Power supply 220-230V 50/60 Hz*

Low voltage/mains insulation > 2MOhm 500V

Operating temperature range -20 / +55°C

Thermal overload protection Software

Dielectric rigidity mains/LV 3750V~ for 1 minute

Motor output current max. 7.5A+7.5A

Motor relay switching current

10A

Maximum motor power 180W + 180W (24V

)

Accessories power supply

24V~ (demand max. 1A)

24V~safe

AUX 0

NO 24V

powered contact (max.1A)

AUX 3

NO contact (24V~/max.1A)

Fuses see Fig. C

N° of combinations 4 billion

Max.n° of transmitters that can be memorized

63

(*other voltages to order)

Usable transmitter versions:

All ROLLING CODE transmitters compatible with

4) TUBE ARRANGEMENT Fi g. A

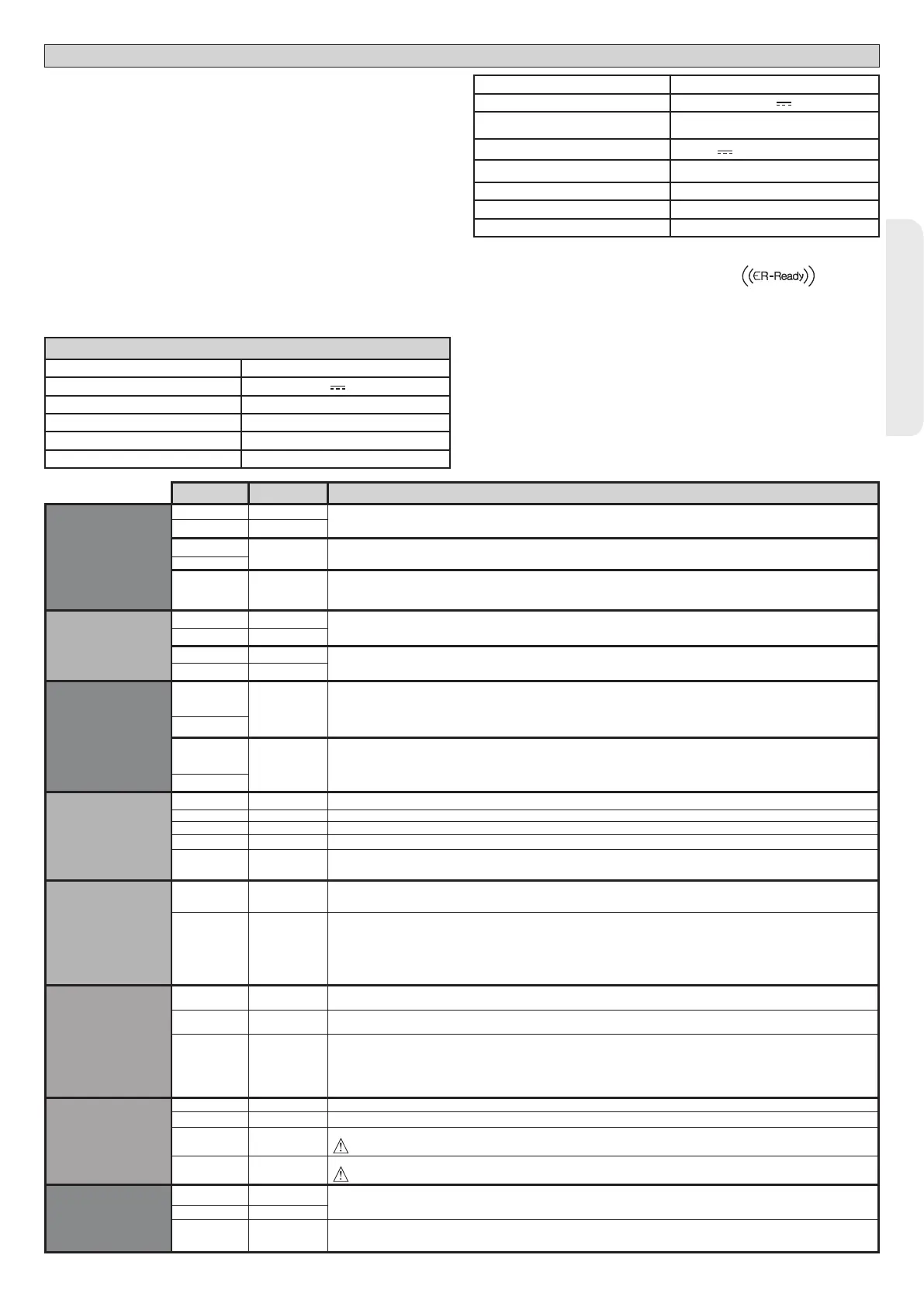

5) TERMINAL BOARD WIRING Fig. C

WARNINGS - When performing wiring and installation, refer to the standards in

force and, whatever the case, apply good practice principles.

Wires carrying dierent voltages must be kept physically separate from each other,

or they must be suitably insulated with at least 1mm of additional insulation.

Wires must be secured with additional fastening near the terminals, using devices

such as cable clamps.

All connecting cables must be kept far enough away from the dissipater.

WARNING! For connection to the mains power supply, use a multicore cable

with a cross-sectional area of at least 3x1.5mm2 of the kind provided for

by the regulations in force. To connect the motors, use a cable with a cross-

sectional area of at least 1.5mm2 of the kind provided for by the regulations

in force. The cable must be type H05RN-F at least.

Terminal Denition Description

Power supply

L LINE

Single-phase power supply

220-230V 50/60 Hz*

N NEUTRAL

JP5

TRANSF PRIM Transformer primary winding connection, 220-230V.

JP7

JP21 TRANSF SEC

Board power supply:

24V~ Transformer secondary winding

24V= Buer battery power supply

Motor

10 MOT1 +

Connection motor 1. Time lag during closing.

Check connections shown in Fig.E

11 MOT1 -

14 MOT2 +

Connection motor 2. Time lag during opening.

Check connections shown in Fig.E

15 MOT2 -

Aux

20

AUX 0 - 24V

POWERED

CONTACT (N.O.)

(MAX. 1A)

AUX 0 congurable output - Default setting FLASHING LIGHT.

2ND RADIO CHANNEL/ SCA GATE OPEN LIGHT/ COURTESY LIGHT command/ ZONE LIGHT command/ STAIR LIGHT/ GATE

OPEN ALARM/ FLASHING LIGHT/ SOLENOID LATCH/ MAGNETIC LOCK/ MAINTENANCE/ FLASHING LIGHT AND MAINTE-

NANCE. Refer to “AUX output conguration” table.

21

26

AUX 3 - FREE

CONTACT

(N.O.)

(Max. 24V 1A)

AUX 3 congurable output - Default setting 2ND RADIO CHANNEL Output.

2ND RADIO CHANNEL/ SCA GATE OPEN LIGHT/ COURTESY LIGHT command/ ZONE LIGHT command/ STAIR LIGHT/ GATE

OPEN ALARM/ FLASHING LIGHT/ SOLENOID LATCH/ MAGNETIC LOCK.

Refer to “AUX output conguration” table.

27

Limit switch for

ELI 250 BT

VIRGO SMART BT A

ELI BT A35 LS

ELI BT A40 LS

5 wires

41 + REF SWE Limit switch common

42 SWC 1 Motor 1 closing limit switch SWC1 (N.C.).

43 SWO 1 Motor 1 opening limit switch SWO1 (N.C.).

44 SWC 2 Motor 2 closing limit switch SWC2 (N.C.).

45 SWO 2 Motor 2 opening limit switch SWO2 (N.C.).

Limit switch for

PHOBOS N BT

IGEA BT

SUB BT

PHOBOS BT A

KUSTOS BT A VIRGO

SMART BT A

3 wires

42 SW 1

Limit switch control motor 1.

For actuators with single-wire limit switch control.

43 SW 2

Limit switch control motor 2.

For actuators with single-wire limit switch control.

Limit switch for

GIUNO ULTRA BT A20

GIUNO ULTRA BT A50

E5 BT A18

E5 BT A12

40 - REF SWE Limit switch common

42 SW 1 Limit switch control motor 1.

43 SW 2 Limit switch control motor 2.

Limit switch for

ELI BT A35 LS

ELI BT A40 LS

40 - REF SWE Encoder power supply, white cable

41 + REF SWE Encoder power supply, brown cable

42 ENC M1

Engine 1 encoder signal, green cable

Close the jumper JP28

43 ENC M2

Engine 2 encoder signal, green cable

Close the jumper JP29

Accessories

power supply

50 24V-

Accessories power supply output.

51 24V+

52 24 Vsafe+

Tested safety device power supply output (photocell transmitter and safety edge transmitter).

Output active only during operating cycle.

THALIA - 31

D814123 0AA00_01

Loading...

Loading...