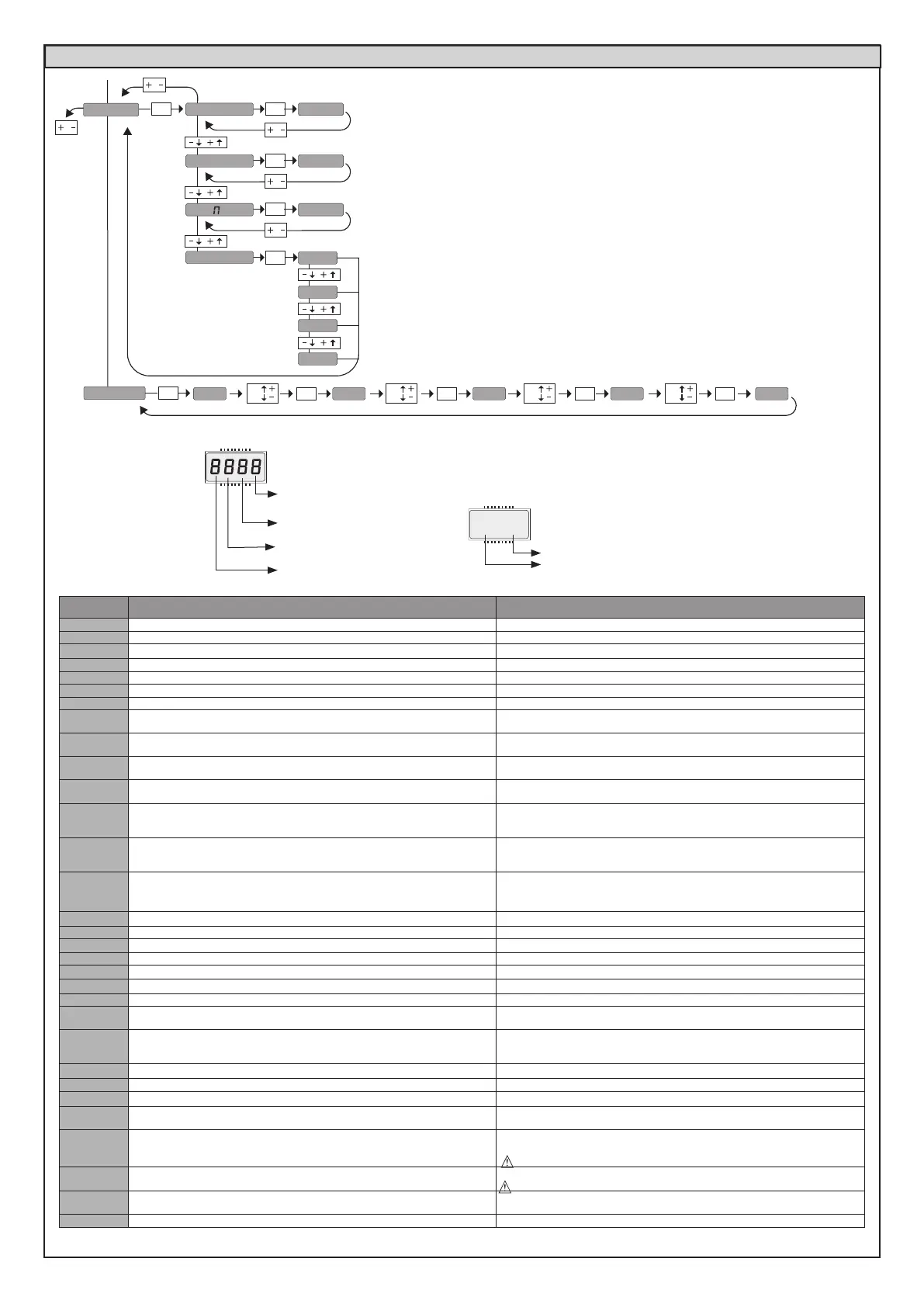

/

OK OK

stat

vers

password

bft. . .

/

/

Err

OK

01.33

02.01

. . . . .

30.15

OK

0--- 10--

OK

150-

OK

1520 prg

OK OK

P1

P2

P1

P2

P1

P2

P1

P2

OK

0000

/

OK

0000

/

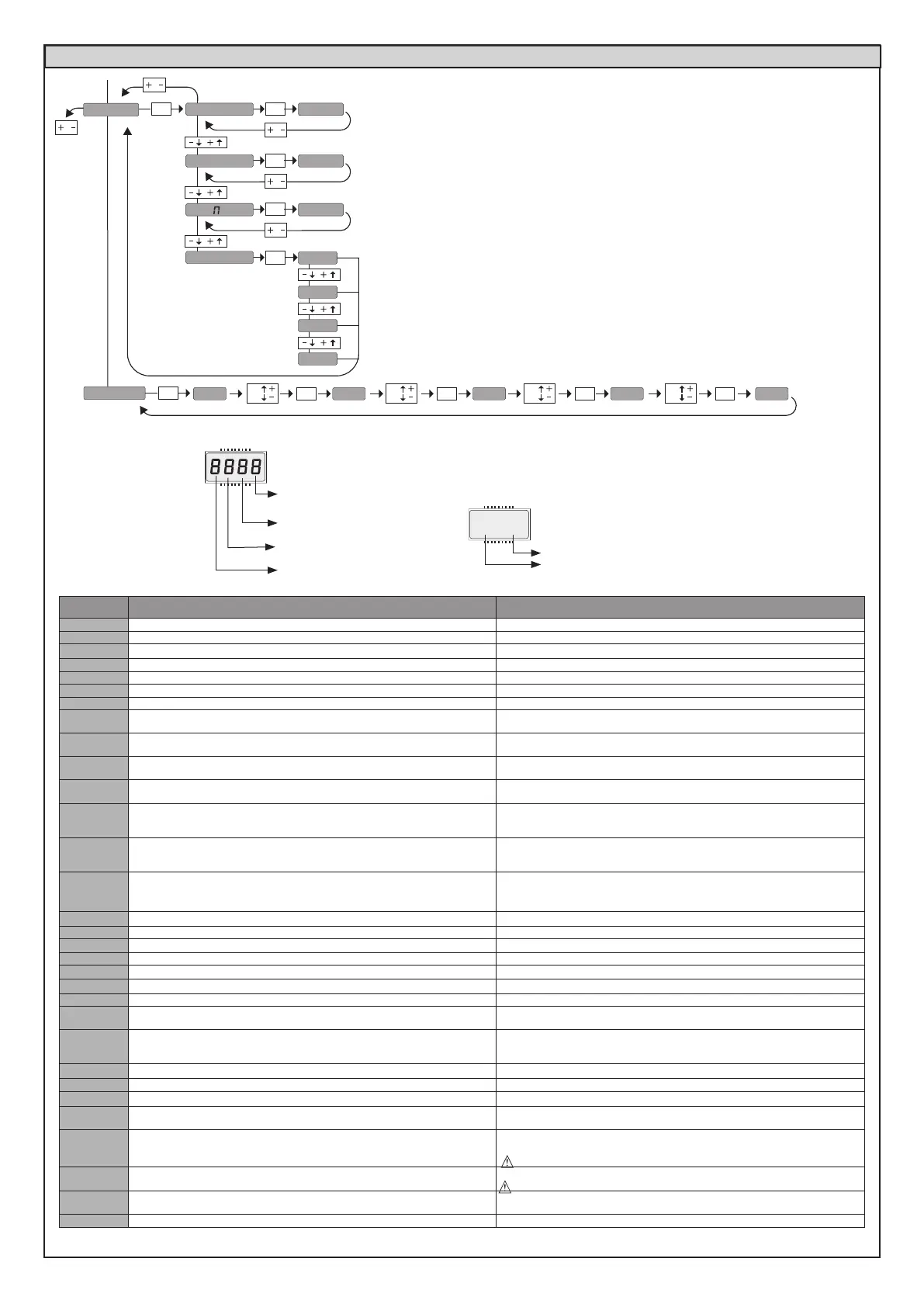

n. cycles

n. re otes

Diagnostics

code

DESCRIPTION NOTES

STRE

START E external start input activated

STRI

START I internal start input activated

OPEN

OPEN input activated

CLS

CLOSE input activated

PED

PED pedestrian input activated

TIME

TIMER input activated

STOP

STOP input activated

PHOT

Activation of PHOT photocell input or, if congured as veried photocell, Activation

of the associated FAULT input

PHOP

Activation of PHOT OP opening photocell input or, if congured as active veried

photocell only when opening, Activation of the associated FAULT input

PHCL

Activation of PHOT CL closing photocell input or, if congured as active veried

photocell only when closing, Activation of the associated FAULT input

BAR

Activation of BAR safety edge input or, if congured as veried safety edge, Acti-

vation of the associated FAULT input

baro

Activation of BAR safety edge input with ACTIVE reversal ONLY WHILE OPENING,

or, if congured as veried safety edge active only while opening, Activation of

the associated FAULT input

barc

Activation of BAR safety edge input with ACTIVE reversal ONLY WHILE CLOSING,

or, if congured as veried safety edge active only while closing, Activation of the

associated FAULT input

SET

The board is standing by to perform a complete opening-closing cycle uninter-

rupted by intermediate stops in order to acquire the torque required for movement.

WARNING! Obstacle detection not active

ER01

Photocell test failed Check photocell connection and/or logic settings

ER02

Safety edge test failed Check safety edge connection and/or logic settings

ER03

Opening photocell test failed Check photocell connection and/or parameter/logic setting

ER04

Closing photocell test failed Check photocell connection and/or parameter/logic setting

er06

8k2 safety edge test failed Check safety edge connection and/or parameter/logic settings

ER07

Opening safety edge test failed Check safety edge connection and/or parameter/logic settings

ER08

Closing safety edge test failed Check safety edge connection and/or parameter/logic settings

ER1x*

Board hardware test error

- Check connections to motor

- Hardware problems with board (contact technical assistance)

ER2x*

Encoder error

- Motor or encoder signal power cables inverted/disconnected or incorrect pro-

gramming (see Fig. E)

- Actuator movement is too slow or stopped with respect to programmed operation.

ER3x*

Reverse due to obstacle - Amperostop Check fo r obstacles in path

ER4x*

Thermal cutout Allow automated device to cool

ER5x*

Communication error with remote devices Check connection with serial-connected accessory devices and/or expansion boards

ER70, ER71

ER74, ER75

Internal system supervision control error.

Try switching the board o and back on again. If the problem persists, contact the

technical assistance department.

ER72

Consistency error of the control unit’s parameters (Logics and Parameters)

Pressing OK the detected settings are conrmed. The board will keep on working

with the detected settings.

The board settings must be checked (Parameters and Logics)

ER73

D-track parameter error

Pressing OK, the board will keep on working with D-track as a default.

An autoset is required

Ersw

Error during limit switch adjustment

Only for E5 BT A18 / E5 BT A12

Motor or encoder signal power cables inverted/disconnected or incorrect

programming. (see Fig. E)

ERf3

Error in the conguration of the logics (SAFE inputs, motor type) Check that the SAFE logic or motor type conguration is correct.

*X= 0, 1, .., 9, A, B, C, D, E, F

Instantaneous force motor 2

Instantaneous force motor 1

35.40

C=

SWC2 motor 2 closing limit

switch input activated

O=

SWO1 motor 1 opening limit

switch input activated

C=

SWC1 motor 1 closing limit

switch input activated

O=

SWO2 motor 2 opening limit

switch input activated

Control unit software version

No total manoeuvres (in hundreds)

No radio control devices memorised

List of last 30 errors

ACCESS MENUS FIG. 1

30 - THALIA

D814123 0AA00_01

Loading...

Loading...