BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

OPERATION

1. Place work piece on bed frame.

2. Locate and close release valve.

3. Pump handle until the ram nears work piece.

4. Apply load to work piece by pumping handle. Do not overload work piece.

5. Remove load from work piece by turning release valve. Stabilize work piece so it does not fall

while pressure is released.

6. Remove work piece after ram is fully retracted.

MAINTENANCE

Periodically, lightly oil all moving parts including the pump piston and hydraulic ram.

Check hydraulic connections and hoses before each use.

Do not use if cut, damaged, leaking or otherwise damaged connections and/or hoses are noted

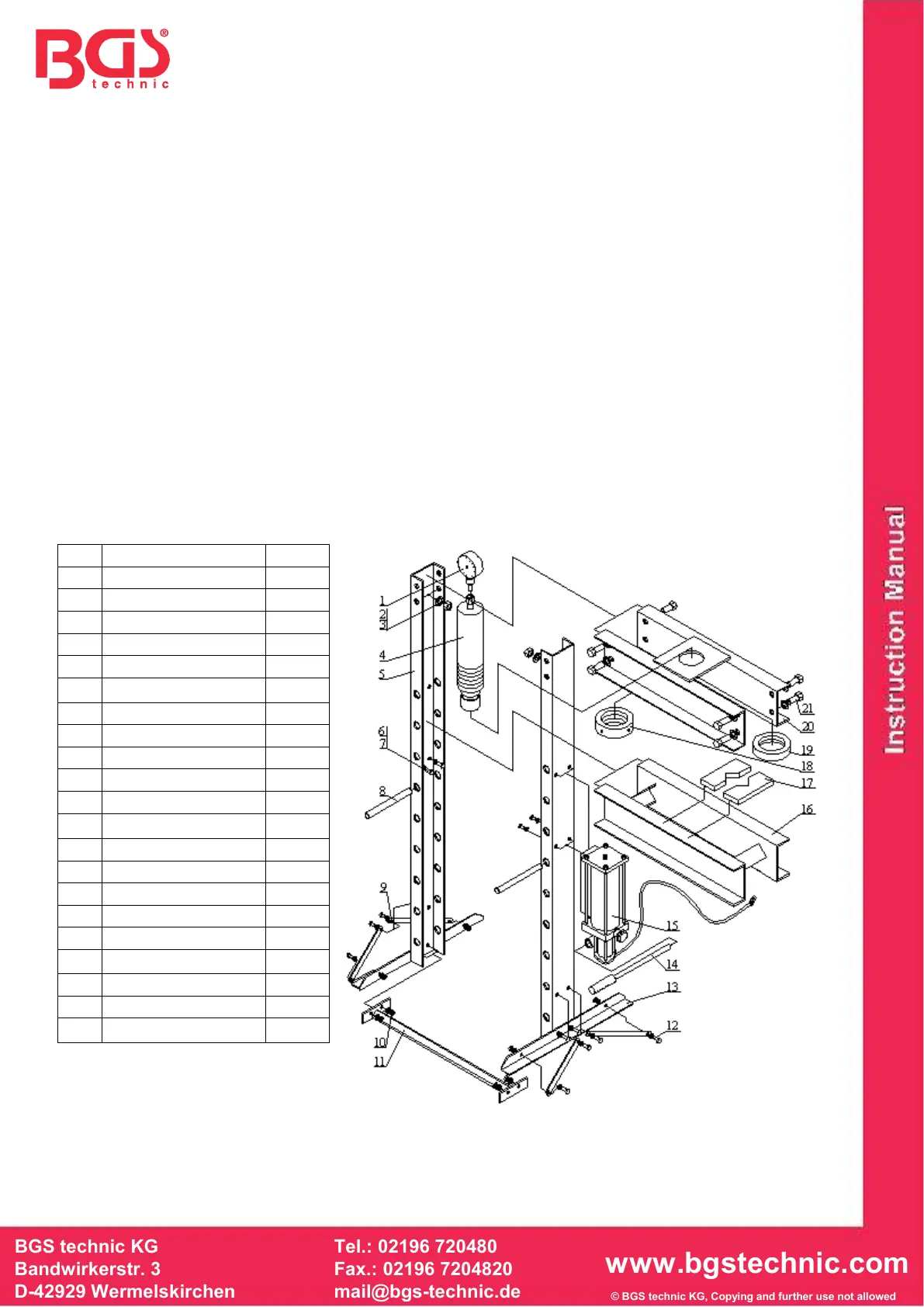

DISASSEMBLE DRAWING

0×15

0×25

6×40

Loading...

Loading...