VI. Appendix BigRep

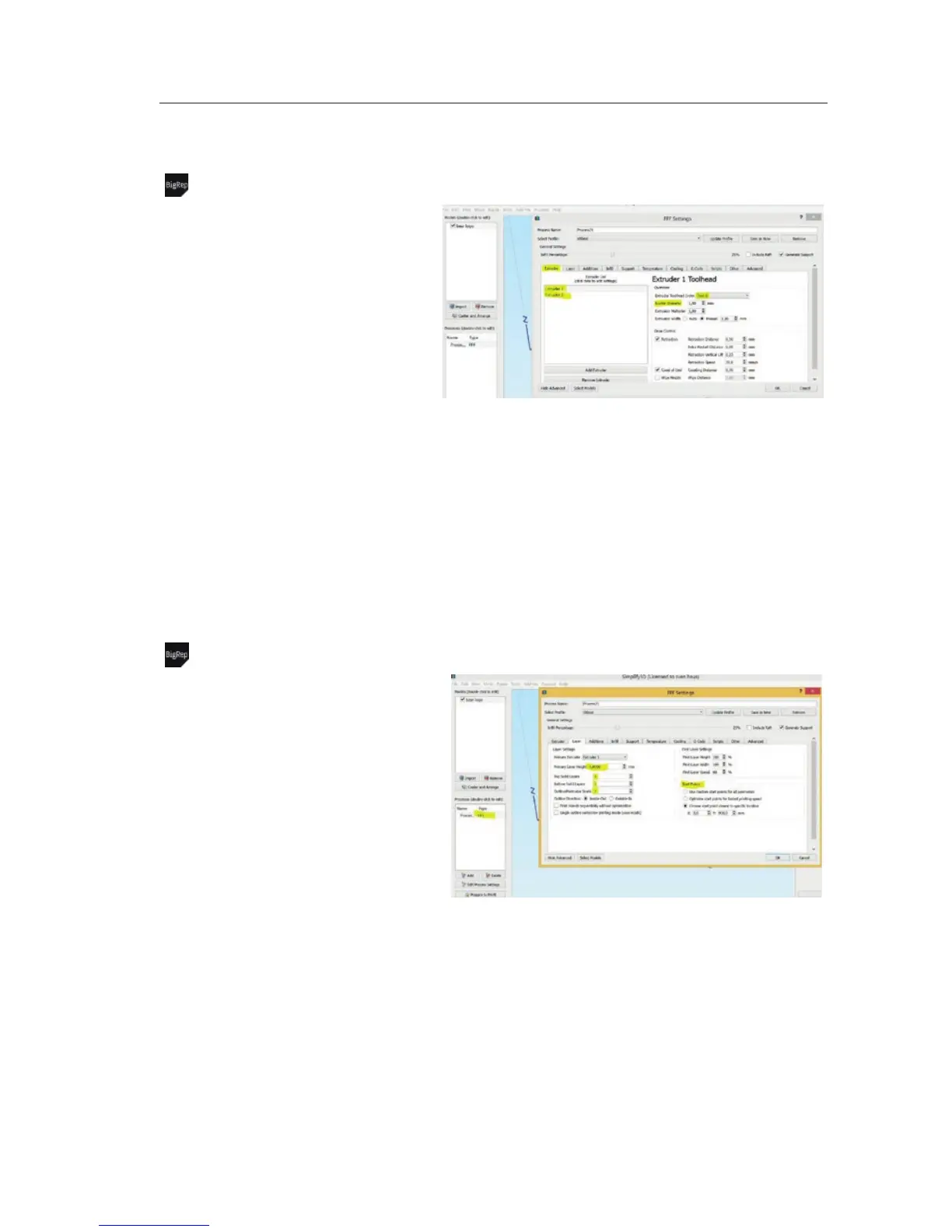

Slicing – most important settings: Extruder

Most important:

• Choose the correct extruder (T0, T1)

• Choose the correct nozzle diameter you have

installed at the machine (.5 or 1mm)

In detail:

• Extrusion Multiplier = Flowrate, choose 1 as

standard

• Extrusion Width = Single Outline Width, 10-20%

more than nozzle diameter is recommended,

but not a must

• Ooze Control = avoid overflow during z-moves,

standard values are recommended

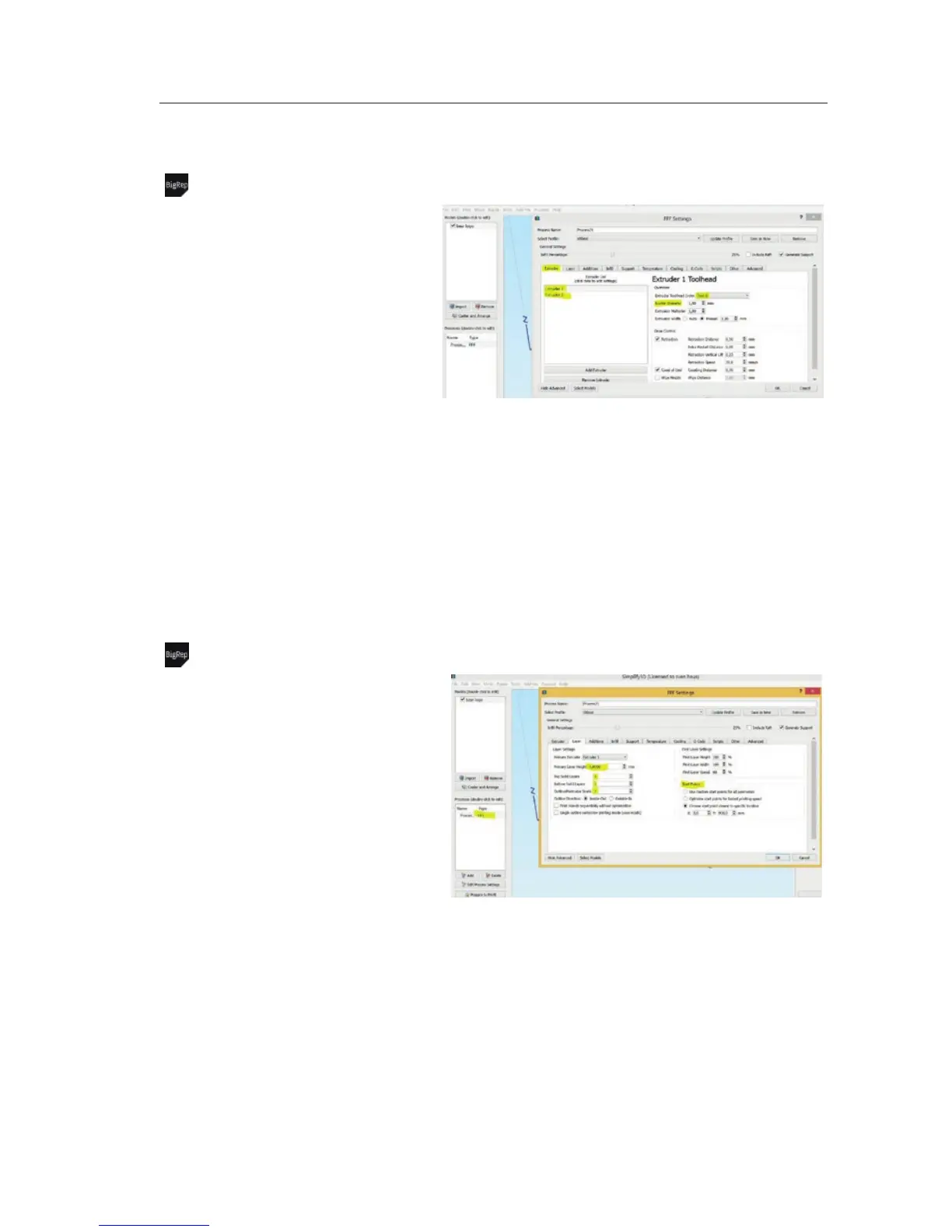

Slicing – most important settings: Layer

Most important:

• Layer Height (resolution) choose

between .6 and 1mm with 1mm nozzle &

between .2 and .5mm with 0.5mm nozzle

In detail:

• Top Solid Layers = number of solid layers at

the top of your sample. Choose at least 2.

Increase if you use little infill.

• Bottom Solid Layers = number of solid layers

at the bottom. 3 are recommended and

most often sufficient

• Outline/Perimeter Shells = number of loops

at the “walls”. Choose the correct amount to

avoid gaps or little infill structure.

• Start Points = the “seam” for z-moves.

Choose start point to for example “hide” the

seam in the back

VI-E 3/7

Loading...

Loading...