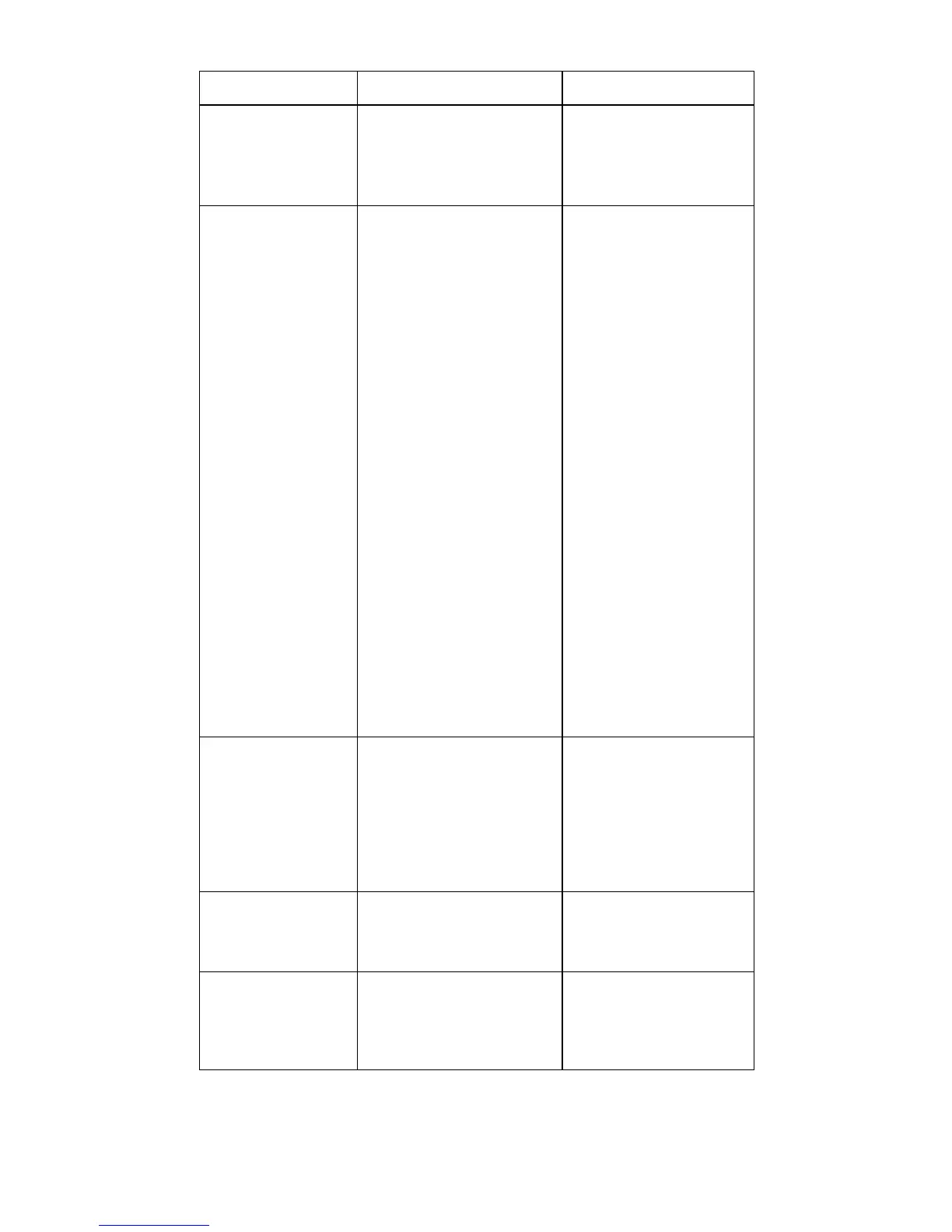

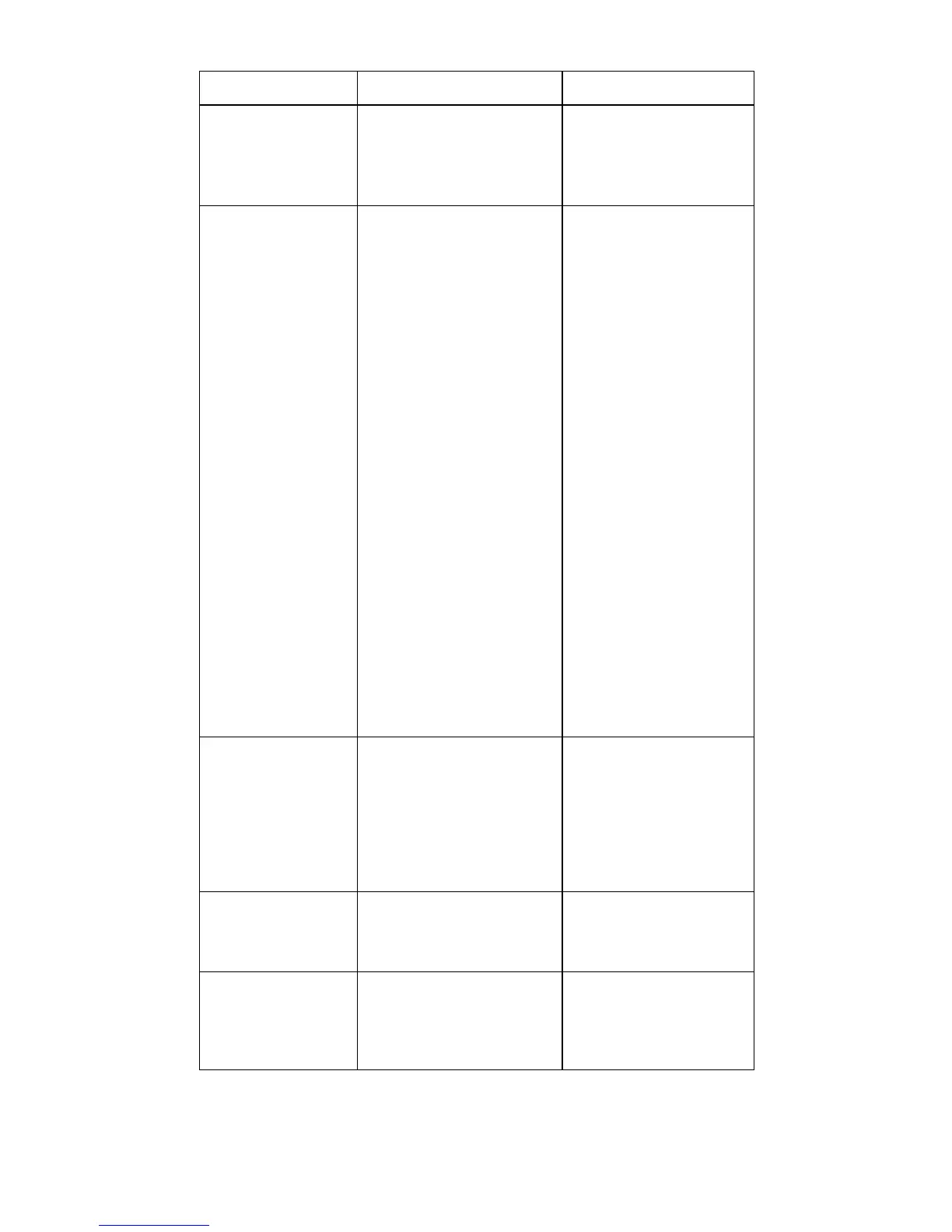

10. Troubleshooting

Trouble Possible cause Solution

Droplets left Unsuitable tip Use original Biohit tips

inside the tip

Non-uniform wetting Attach new tip

of the tip plastic

Leakage or Tip incorrectly attached Attach firmly

pipetted volume

too small Unsuitable tip Use original Biohit tips

Foreign particles Clean the tip cone,

between tip and tip attach new tip

cone

Instrument Clean and grease

contaminated O-ring and piston,

clean the tip cone (*)

Insufficient amount of Grease accordingly

grease on piston and

O-ring

O-ring not correctly Change the O-ring

positioned or damaged

Incorrect operation Follow instructions

carefully

Calibration altered or Recalibrate according

unsuitable for the liquid to instructions

Instrument damaged Send for service

Push button Piston contaminated Clean and grease

jammed or O-ring and piston,

moves erratically clean the tip cone (*)

Penetration of solvent Clean and grease

vapours O-ring and piston,

clean the tip cone (*)

Pipettor blocked, Liquid has penetrated Clean and grease

aspirated volume tip cone and dried O-ring and piston,

too small clean the tip cone (*)

Tip ejector Tip cone and/or ejector Clean the tip cone and

jammed or collar contaminated the ejector collar (*)

moves

erratically

(*) Clean with Biohit Proline Biocontrol or 75% ethanol.

46

Loading...

Loading...