12

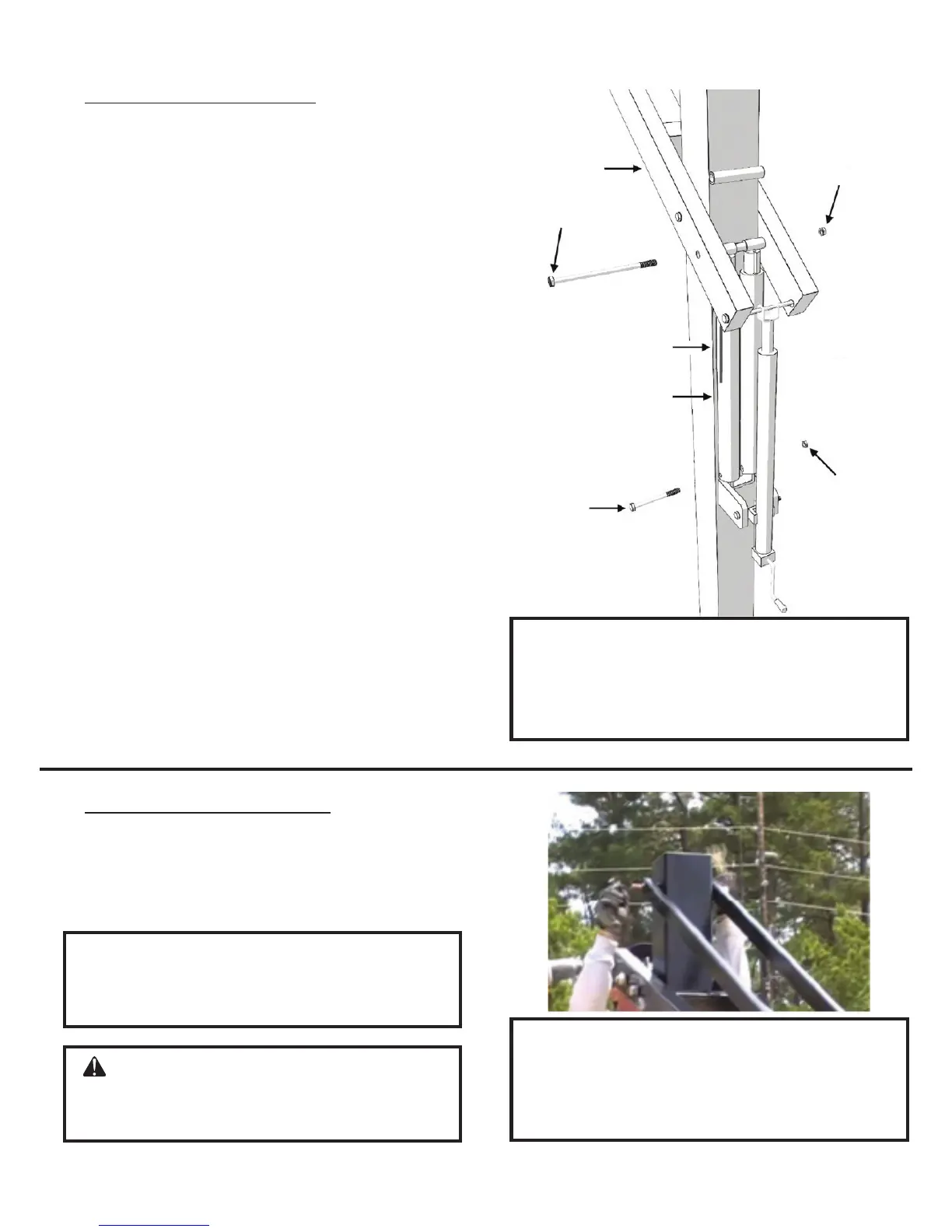

8) Spring Assist Assembly

Attach Spring-Assist Cartridges (E) to the

Main Extension Arm (B) using a 3/4” X 12 1/2”

Hex Bolt (P) and 3/4” Lock Nut (Q). The

Orange Rim Height Indicator (G) must slide

onto the 3/4“ x 12 1/2” Hex Bolt (P) on

whichever side you wish to install the height

indicator label shown in instruction #14. In

order to attach both Spring-Assist Cartridges

(E) at the bottom, lower the open end of each

Spring-Assist Cartridges (E) down over the

top of each welded tab as shown in the

diagram. You will use the Crank Adjustment

Cylinder to help align the lower mounting

holes. Use the 5/8” X 8” Hex Bolt (I) and 5/8”

Lock Nut (J) to attach them to the welded

tabs. You may need to turn or rotate the

Spring-Assist Cartridges (E) to line up holes.

The Rim Height Indicator (G) should hang

freely along the ouside of one of the

Spring-Assist Cartridges (E). Next, remove

and discard the plastic spring assist spacer

from Spring-Assist Cartridges (E).

NOTE: Tighten the lock nuts down

and then back off a 1/4 turn to allow

the joint to pivot when adjusting the

system up and down.

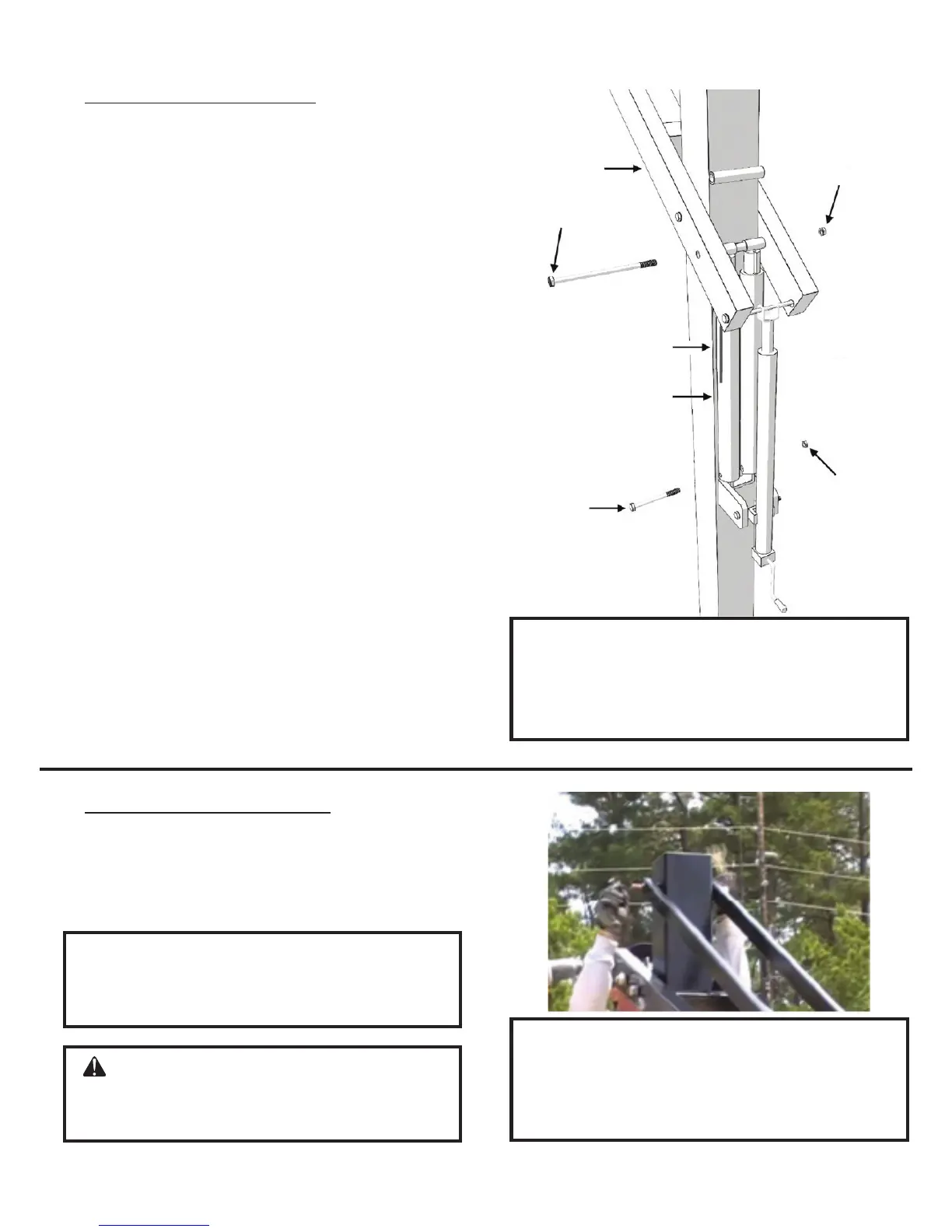

9) Upper Linkage Assembly

Attach Parallel Linkages (C) to Vertical

Post (A) with a 3/4” X 11 1/4” Hex Bolt (O)

and a 3/4” Lock Nut (Q).

NOTE: Tighten the lock nuts down

and then back off a 1/4 turn to allow

the joint to pivot when adjusting the

system up and down.

CAUTION: Injury may occur if

linkages are allowed to fall from main

arm during assembly.

NOTE: It does not matter which end

of the parallel link you attach to the

vertical post.

(B)

(Q)

(P)

(G)

(J)

(I)

(E)

REV. 10/10/17

Loading...

Loading...