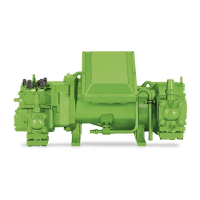

Do you have a question about the Bitzer HSN8571-125 and is the answer not in the manual?

| Brand | Bitzer |

|---|---|

| Model | HSN8571-125 |

| Category | Air Compressor |

| Language | English |

Ensures only trained staff perform work on compressors and refrigeration systems.

Provides instructions to prevent hazards and guide safe operation, covering potential dangers.

Details permitted refrigerants, oil charge, and operating limits for compressors.

Warns of chemical reactions and pressure increases due to air entering the system.

Guidelines for safely transporting the compressor, either on a pallet or using lifting eyes.

Instructions for setting up the compressor horizontally, including anti-vibration mountings.

Advises against rigid mounting on heat exchangers and recommends anti-vibration dampers.

Details on connecting pipes, including types of connections and soldering precautions.

Warnings regarding overheating valves, dismantling connections, and using clean/dry pipes.

Highlights risks of short circuits from condensation and emphasizes proper sealing of cable entries.

Describes a special HS.85 version for booster applications, requiring an external oil pump.

Explains the "Dual Capacity Control" system for 4-step or infinite capacity adjustment.

Details 4-step and infinite capacity control ranges (100%-50%, 100%-25%).

Warns that application ranges are restricted when using capacity control.

Lists and describes various connection points on the compressor for different functions.

Information on the integrated oil filter, its replacement, and the oil management system.

Recommends fitting additional connections for evacuation on large systems.

States compliance with EC directives and emphasizes following wiring diagrams and safety standards.

Warns of short circuits due to condensation and stresses proper grounding and cable sealing.

Guidance on selecting motor contactors, cables, and fuses based on operating current.

Warns of motor damage from incorrect wiring or phase angle issues.

Emphasizes operating compressors only in the prescribed rotating direction to prevent failure.

Notes factory high-voltage testing and advises on performing reduced voltage tests cautiously.

Outlines motor protection devices and their functions, warning against incorrect connections.

Describes the standard SE-E1 device, its monitoring functions, and connections.

Specifies the need for SE-C2 or SE-E2 devices when operating with frequency inverters.

Explains the necessity of pressure limiters to define operating ranges and avoid inadmissible conditions.

Describes the system's components for oil supply, rotation, and filter monitoring.

Details the function of the oil separator and the installation of an oil heater.

Advises insulating the oil separator in specific low or high ambient temperature conditions.

Emphasizes safety during commissioning, warning against improper pressure testing and refrigerant mixing.

Guides on testing the refrigerant circuit's pressure resistance according to standards, warning about test pressure limits.

Warns against filling oil directly into the compressor and details the correct procedure for oil filling.

Warns of compressor/motor damage if started under vacuum or if voltage is applied.

Details the process of charging permitted refrigerants, including oil heating and checking oil levels.

Warns about the danger of "wet operation" and the need for precise liquid refrigerant charging.

Highlights the risk of component explosion due to hydraulic overpressure and avoiding system overcharging.

Explains that insufficient refrigerant leads to low suction pressure and high superheating.

Lists essential checks before starting the compressor, including oil level, temperature, and safety devices.

Provides a method to test the compressor's rotating direction to prevent damage.

Details how to perform a phase sequence test to ensure correct wiring order.

Step-by-step guide for starting the compressor, including opening the suction valve and observing oil flow.

Explains how to test the oil supply monitoring system by unplugging a connection.

Warns about wet operation and potential issues if oil monitoring systems trigger.

Details setting the temperature control for the oil cooler based on refrigerant type.

Guides on accurately setting switch-on/cut-out pressures according to application limits.

Instructions on setting condenser pressure for optimal performance and avoiding rapid pressure drops.

Lists essential operating data to check, such as temperatures and cycling rates.

Warns about compressor damage if specific operational requirements (cycling rate, run time) are not met.

Stresses checking for abnormal vibrations in the entire plant and taking measures to avoid them.

Provides insights into common compressor failures and specific advice for safe operation.

Details correct positioning of the temperature bulb and ensuring sufficient superheat for expansion valves.

Advises on preventing refrigerant migration during longer standstill periods.

Specifies the recommended oil temperature relative to ambient temperature during compressor start-up.

Discusses the benefits of using a heat exchanger with HFC refrigerants for improved efficiency.

Lists essential points for regular plant inspection, including operating data, lubrication, and safety devices.

Briefly describes the function of internal pressure relief valves, check valves, and oil stop valves.

Warns of potential injuries if the compressor is under pressure and not properly depressurized.

Recommends initial oil filter change and outlines permanent monitoring of clogging.

Highlights that the oil filter chamber and compressor are independent pressure chambers, warning of serious injury.

Step-by-step guide for safely changing the oil filter, including depressurizing and proper sealing.

Warns that the oil separator is under pressure and requires depressurization before handling.

Advises caution with ester oils due to their hygroscopic nature and the need to avoid air entry.

Advises keeping the oil heater on during standstill to prevent refrigerant diffusion into the oil.

Guides on safely dismantling the compressor, extracting refrigerant, and proper disposal procedures.

Warns that the compressor may be under pressure and requires safety goggles during dismantling.

Loading...

Loading...