Do you have a question about the Bitzer OSNA8571-K and is the answer not in the manual?

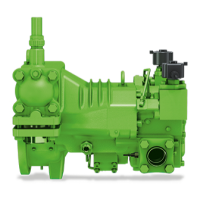

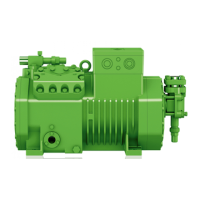

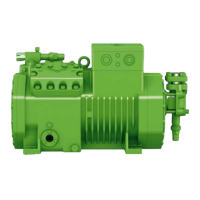

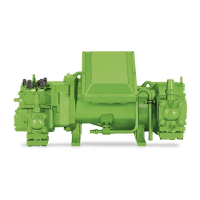

Highlights the OS.85 compressors' innovation, efficiency, and key technical attributes.

Details the compression process and the Vi-control for varying internal volume ratios.

Explains the dual capacity control system allowing infinite or stepped regulation.

Covers the automatic start unloading feature to reduce starting torque.

Details the compressor start-up sequence, including unloading.

Recommends infinite capacity control for systems requiring high accuracy.

Details the integrated oil management system and its components.

Explains thermosiphon oil cooling principles and its application.

Presents a table of lubricants for HFC and R22 refrigerants with their properties.

Details the pump down system requirements and function.

Covers requirements for the expansion valve, including sensor positioning.

Explains the integrated capacity control feature.

Details the necessity of pressure control for optimal oil supply and efficiency.

Covers integrated and additional start unloading methods like bypass.

Explains the function of the integrated ECO port in the control slider.

Details ECO operation using a heat exchanger as a liquid subcooler.

Guides on selecting liquid subcoolers based on heat exchangers and software data.

Covers valve layout and selection for liquid subcoolers and evaporators.

Lists explosion-proof compressor models available upon request.

Lists explosion-proof oil separator models available upon request.

Details central power factor correction and its requirements.

Details SE-B2 monitoring functions for temperature and oil flow.

Explains oil flow monitoring.

Covers monitoring of rotation direction and oil stop valve.

Explains oil filter monitoring.

Details OFC monitoring function for oil flow.

Lists SE-C2 monitoring functions for rotation direction, oil flow, temperature, and cycling rate.

Covers SE-C2 monitoring of compressor cycling rate.

Details the standard monitoring concept with SE-B2.

Explains the delay control for activating ECO operation.

Shows a simplified schematic for automatic pump down.

Shows a simplified schematic for single pump down.

Explains compressor switching based on suction pressure for pump down.

Lists technical data for standard OS.85 compressors.

Lists technical data for OS.A85 NH3 compressors.

Guides through selecting language, units, and output headers.

Describes the main menu options for selecting compressors or cooling capacity.

Guides on selecting the "Open Drive Screws" main menu.

Instructs to select the desired compressor model.

Explains how to calculate and access accessories after model selection.

Guides on how to select the "Open Drive Screws" main menu.

| Model | OSNA8571-K |

|---|---|

| Refrigerant | R22, R134a, R407C, R404A, R507 |

| Weight | 950 kg |

| Power Input | 15.0 kW |

| Frequency | 50 Hz |

| Sound Power Level | 85 dB(A) |

| Displacement (1450 RPM) | 857.1 cm³ |

| Motor Power | 15.0 kW |

| Oil Pump | Integrated |

| Dimensions (LxWxH) | 580 mm |