Do you have a question about the Bitzer ECOLINE and is the answer not in the manual?

Details qualifications and training for personnel handling compressors.

Identifies inherent risks associated with compressors.

Provides overall safety guidelines and hazard classifications.

Specifies permitted refrigerants and oil types for compressor models.

Warns about the dangers of air entering the system.

Instructions for safely moving and handling compressors.

Guidance on positioning and installing compressors correctly.

Details on removing transport securing devices from units.

Describes different types of anti-vibration mountings and their installation.

Instructions for connecting refrigerant and control lines to the compressor.

Guidance on the operation and safety of shut-off valves.

Explains fitting cylinder heads for start unloading or capacity control.

Specifics for 8-cylinder models regarding start unloading.

Information on the CRII system for capacity control in ECOLINE compressors.

Visual representations of compressor connection ports for various models.

Detailed listing and explanation of connection point functions and types.

Overview of electrical connection standards and safety.

Guidelines for dimensioning motor contactors, cables, and fuses.

Description of motors for direct on-line start (star/delta).

Details on part winding motors and their contactor selection.

Information on motor protection devices (SE-B1, SE-B2).

Details on the optional differential oil pressure switch.

Instructions for fitting and connecting the discharge gas temperature sensor.

Purpose and connection guidelines for HP/LP pressure limiters.

Explains the function of the crankcase heater and when to use it.

Details on the CIC system for thermal application limits.

Procedure for testing the pressure strength of the system.

Method for verifying the leak tightness of the refrigerant circuit.

Steps for evacuating the system using a vacuum pump.

Instructions for safely charging refrigerant into the system.

Procedures for checking oil level and temperature before starting.

Immediate checks for lubrication and oil pressure after starting.

Details on optional oil pressure monitoring systems.

Information on the OLC-K1 optical oil level monitoring system.

Guidelines for identifying and mitigating abnormal vibrations and resonances.

Specifies the maximum allowed start frequency and minimum running times.

Routine inspections for operating data, oil supply, and protection devices.

Checks for secure electrical cable connections and tightening torques.

Measures to prevent and manage condensation water in terminal boxes.

Guidelines for replacing compressor oil, including frequency and oil types.

Steps to follow before dismantling the compressor.

Instructions for safely taking apart the compressor.

Procedures for environmentally responsible disposal of compressors.

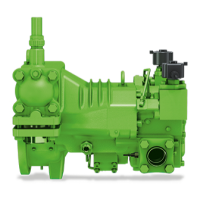

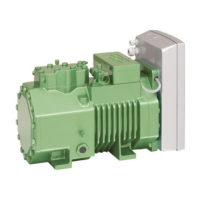

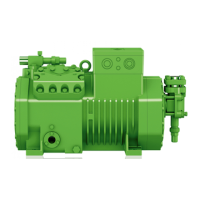

| Brand | Bitzer |

|---|---|

| Model | ECOLINE |

| Category | Air Compressor |

| Language | English |

Loading...

Loading...