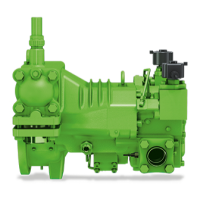

Halbhermetische

Hubkolbenverdichter

OCTAGON Serie

2KC-05.2(Y) .. 4NCS-20.2(Y)

22EC-4.2(Y) .. 44NCS-40.2(Y)

4FDC-5Y .. 4NDC-20Y

4VES-6Y .. 4NES-20Y

44VES-12Y .. 44NES-40Y

Inhalt

Seite

1 Sicherheit

1

2 Anwendungsbereiche

3

3 Montage

4

4 Elektrischer Anschluss

13

5 In Betrieb nehmen

17

6 Betrieb / Wartung

22

7 Außer Betrieb nehmen

24

1 Sicherheit

Diese Kältemittel-Verdichter sind zum

Einbau in Maschinen entsprechend

der

EG-Maschinenrichtlinie

2006/42/EG vorgesehen. Sie dürfen

nur in Betrieb genommen werden,

wenn sie gemäß vorliegender

Montage-/Betriebsanleitung in diese

Maschinen eingebaut worden sind

und als Ganzes mit den entsprechen-

den gesetzlichen Vorschriften überein-

stimmen (anzuwendende Normen:

siehe Hersteller-/Einbauerklärung).*

Autorisiertes Fachpersonal

Sämtliche Arbeiten an Verdichtern

und Kälteanlagen dürfen nur von

Fachpersonal ausgeführt werden,

das in allen Arbeiten ausgebildet

und unterwiesen wurde. Für die

Qualifikation und Sachkunde des

Fachpersonals gelten die jeweils gül-

tigen Richtlinien.

Semi-hermetic

reciprocating compressors

OCTAGON Series

2KC-05.2(Y) .. 4NCS-20.2(Y)

22EC-4.2(Y) .. 44NCS-40.2(Y)

4FDC-5Y .. 4NDC-20Y

4VES-6Y .. 4NES-20Y

44VES-12Y .. 44NES-40Y

Content

Page

1 Safety

1

2 Application ranges

3

3 Mounting

4

4 Electrical connection

13

5 Commissioning

17

6 Operation / Maintenance

22

7 De-commissioning

24

1 Safety

These refrigeration compressors are

intended for installation in machines

according to the

EC Machines

Directive

2006/42/EC. They may be

put to service only, if they have been

installed in these machines according

to the existing Assembly/Operating

Instruction and as a whole agree with

the corresponding provisions of leg-

islation (standards to apply: refer to

Declaration of Manufacturer/of

Incorporation).*

Authorized staff

All work on compressor and refrigera-

tion systems shall be carried out only

by refrigeration personnel which has

been trained and instructed in all

work. The qualification and expert

knowledge of the refrigeration person-

nel corresponds to the respectively

valid guidelines.

Ïîëóãåðìåòè÷íûå

ïîðøíåâûåêîìïðåññîðû

ñåðèèOCTAGON

2KC-05.2(Y) .. 4NCS-20.2(Y)

22EC-4.2(Y) .. 44NCS-40.2(Y)

4FDC-5Y .. 4NDC-20Y

4VES-6Y .. 4NES-20Y

44VES-12Y .. 44NES-40Y

Ñîäåðæàíèå

Ñòð.

1

Ïðàâèëàòåõíèêèáåçîïàñíîñòè

1

2

Îáëàñòèïðèìåíåíèÿ

3

3

Ìîíòàæ

4

4

Ýëåêòðè÷åñêîåïîäêëþ÷åíèå

13

5

Ââîäâýê ñïëó àòàöèþ

17

6

Ýêñïëó àòàöèÿ/Îáñëóæèâàíèå

22

7

Âûâîäèçýê ñïëó àòàöèè

24

1 Ïðàâèëàòåõíèêèáåçîïàñíîñòè

Äàííûåõîëî äèëüíûåê îìïðåññîðû

ïðåäíàçíà÷åíûäëÿóñòàíîâêèâ

ìàøèíû

ñîãëàñíîÏðåäïèñàíèþ ÅÑ

2006/42/EÑ.

Ââîäýòèõêîìïðåññîðîââýêñïëó àòàöèþ

äîïóñêàåòñÿòî ëüêîâòîìñëó÷àå ,

åñëèîíèóñòàíîâëåíûâìàøèíûâ

ñîîòâåòñòâèèñíàñòîÿùåéèíñòðóêöèåéè

âêîìïëåê ñåóäîâëåòâîðÿþòòðåáîâàíèÿì

ñîîòâåòñòâóþùèõïðåäïèñàíèé

(ïðèìåíÿåìûåíîðìû:ñì.Äåêëàðàöèþ/

Óñò àíîâêàèçã îòîâèòåëÿ).*

Ñïåöèàëèñòû, äîïóñ êàåìûåêðàáîòå

Êâûïîëíåíèþðàáîòíàêîìïðåññîð àõè

õ îëîäèëüíûõóñòàíîâêàõäîïó ñêàþòñÿ

òî ëüêîñïåöèàëèñòû,ê îòîðûåïîâñåì

âèäàìðàáîòûïîäâåðãëèñüîáó÷åíèþè

èíñòðóêòàæó.Äëÿêâàëèôèêàöèèèçíàíèÿ

ñïåöèàëèñòîâäåéñòâóþòñîîòâåòñòâåííî

äåéñòâóþùèåäèðåêòèâû.

* Hinweis gilt für Länder der EU * Information is valid for countries of the EC

*

ÓêàçàíèåäåéñòâóåòäëÿñòðàíÅÑ

ÈÍÑÒÐÓÊÖÈß ÏÎ ÇÊÑÏËÓÀÒÀÖÈÈ

KB-100-6-RUS

Loading...

Loading...