201-A00 page 4/12

INSTALLATION

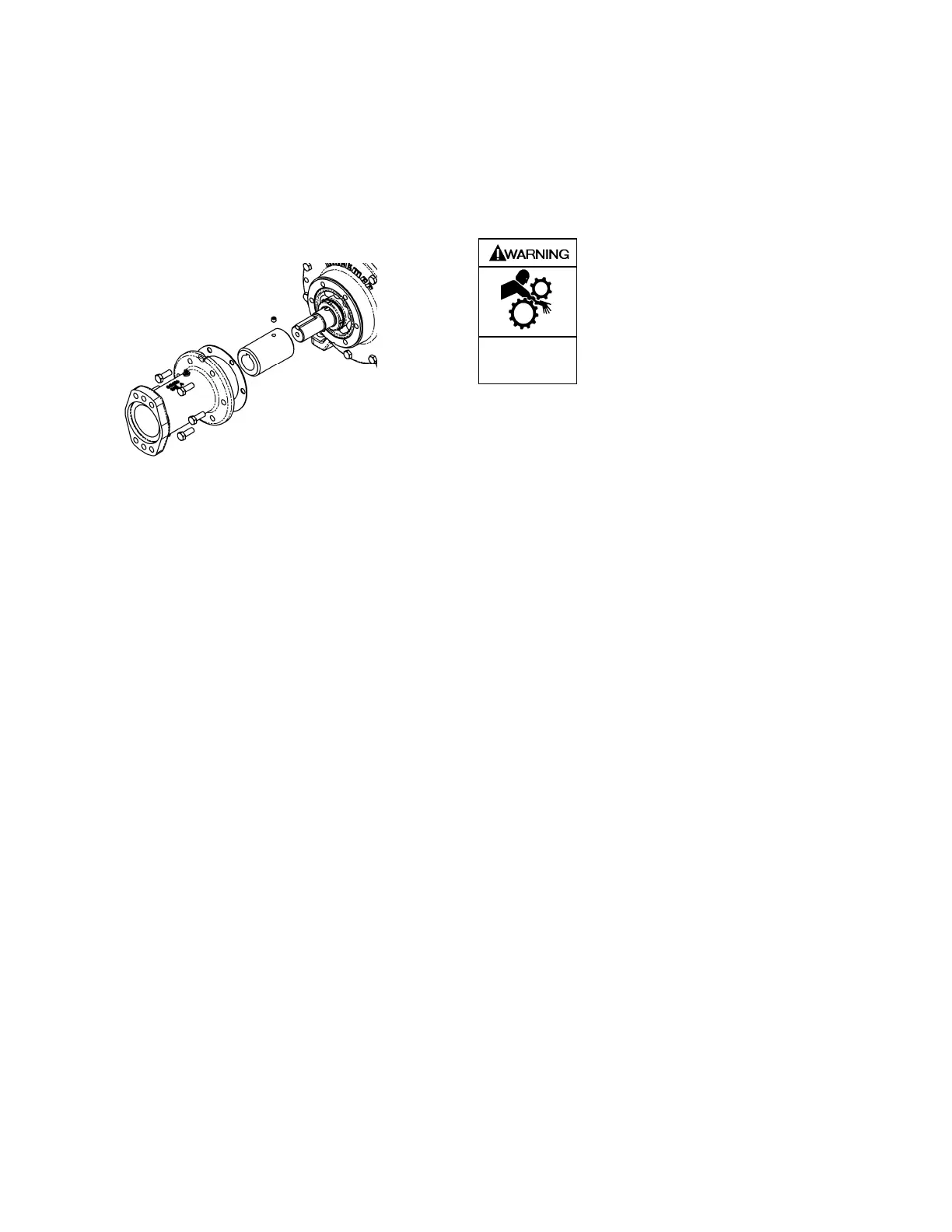

Hydraulic Drive

Pump sizes 1.5” – 3” may also be driven hydraulically.

Hydraulic motors need to be well supported with their shafts

parallel to the pump shaft in all respects. Blackmer provides

an optional close-coupled hydraulic motor adapter. The

adapter provides for straight alignment of a hydraulic motor

drive through a solid coupling connected to a straight key

shaft. This coupling connection requires grease lubrication

every three months at minimum. Refer to the "Lubrication"

section of this manual.

Figure 3 Hydraulic Drive

PUMP ROTATION

NOTICE:

Confirm correct pump rotation by checking the pump

rotation arrows respective to pump driver rotation.

TO CHANGE PUMP ROTATION

TXD Models

The TXD pump models are equipped with a double ended

rotor and shaft, enabling them to be driven from either shaft

end. To change rotation, rotate the pump 180 degrees so that

the opposite shaft becomes the driven shaft. On TXD pump

models, the shaft protector (186) MUST be mounted over the

non-driven shaft end.

Operation without shaft protector can

cause serious personal injury, major

property damage, or death.

Do not operate

without guard

in place

TX1.5, TX4 Models

To reverse rotation, the pump must be disassembled then

reassembled with the shaft on the opposite side of the pump.

See the ‘Maintenance’ section for instructions.

Loading...

Loading...