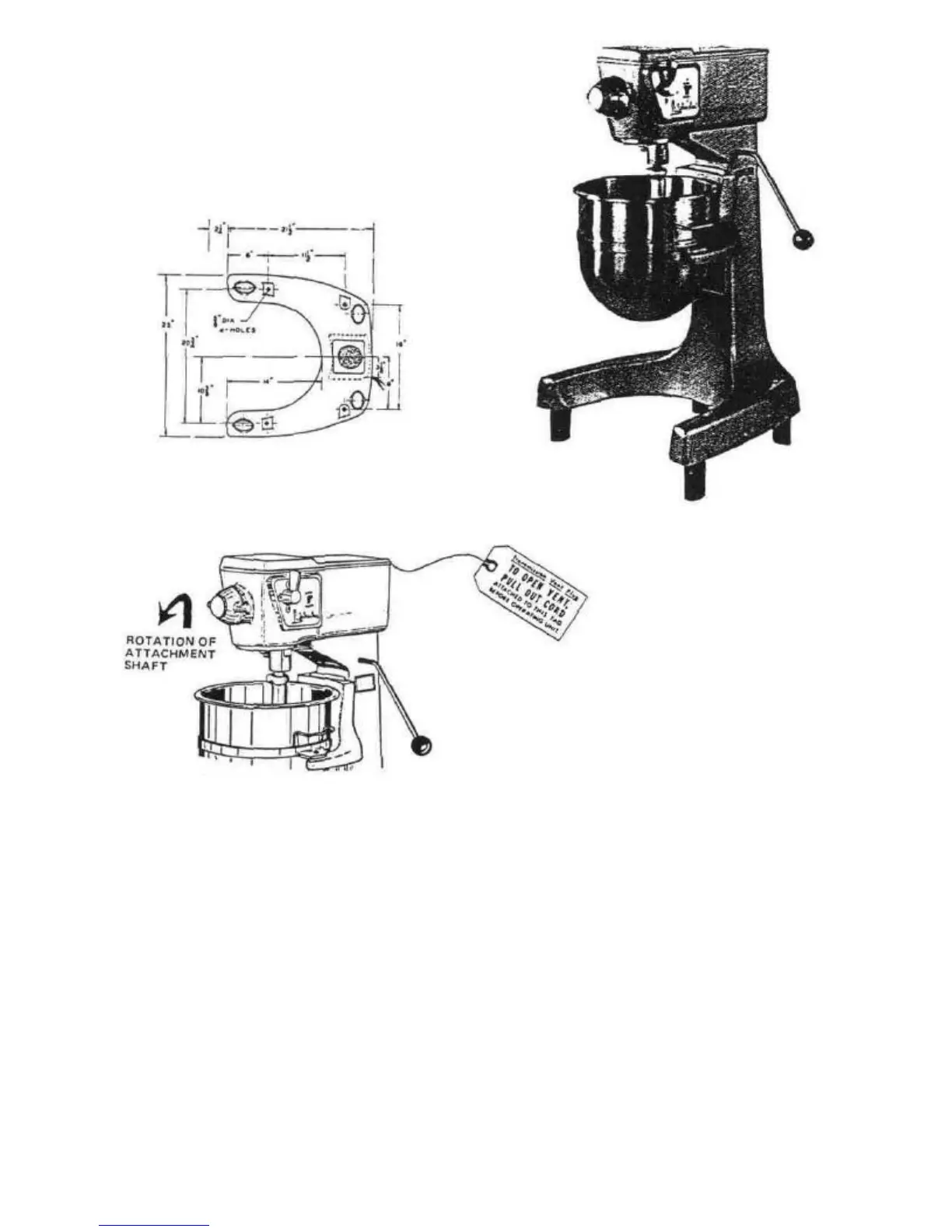

FLOOR MODELS F20, F30

Holes are provided for anchoring the mixer to the

floor, but unless desired, bolting to the floor is not

necessary except on shipboard use.

GENERAL FOR ALL MODELS

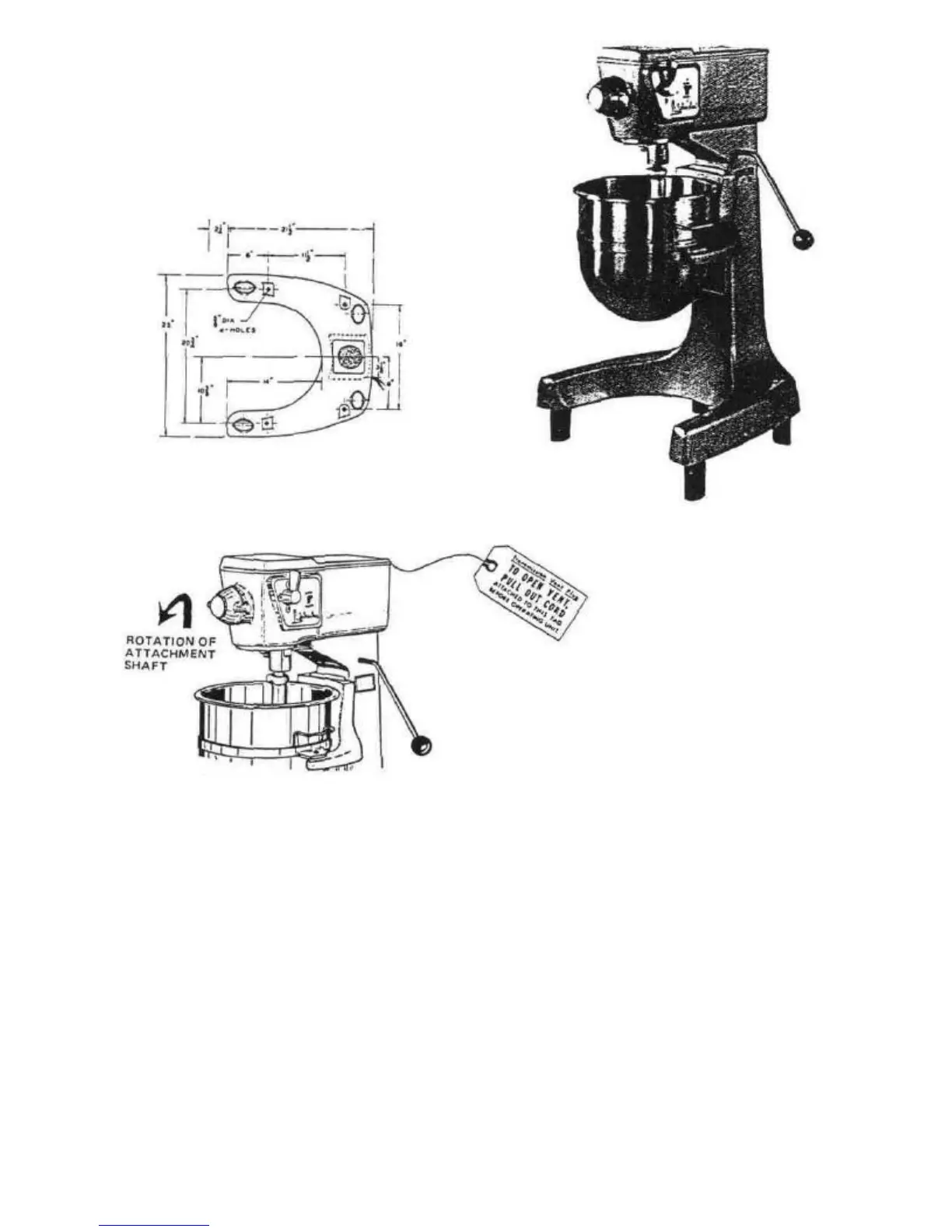

1. VENT PLUG SEAL REMOVAL

Remove vent plug seal from

transmission case. Vent plug has been

sealed with wax for shipment. To

remove seal, pull on tagged string. Seal

will completely pull out leaving vent open

and machine ready to run.

2. ELECTRICAL CONNECTIONS

CAUTION: Before making electrical connections be sure that current and voltage of the mixer are identical to those of electrical

inlet lines.

12 and 20 quart, 110 volt mixers are furnished with a six (6) foot flexible cord. Cords for single phase motors are supplied with a 3

prong plug. Cords for 3 phase motors are supplied with a 4 prong plug.

On 30 quart mixers the line cord is to be supplied by the customer. Connections are made inside the mixer column through

cover plate located on back side of column near the bottom. NOTE: A six (6) foot flexible, three (3) prong plug cord is

available as an extra cost option.

IMPORTANT: On 3 phase mixers, after electrical connection has been made, be sure the mixer operates in a counter-clockwise

direction as indicated by the arrow located above the attachment. Remove hub cover to observe shaft rotation. If electrical

connection is reversed the transmission will not shift, nor will the planetary action function.

3. TRANSMISSION OIL

After the first 200 hours of operation and every 6 months or 1000 hours of operation thereafter the transmission oil must be

changed.

When adding or changing transmission oil use #50 heavy duty oil (Hydrol Master 500 or equivalent)

3 pints — M-5-3330 Trans.

4 pints — M-5-1505 Trans.

3

Loading...

Loading...