EBE 350 E Operating Instructions

Maintenance

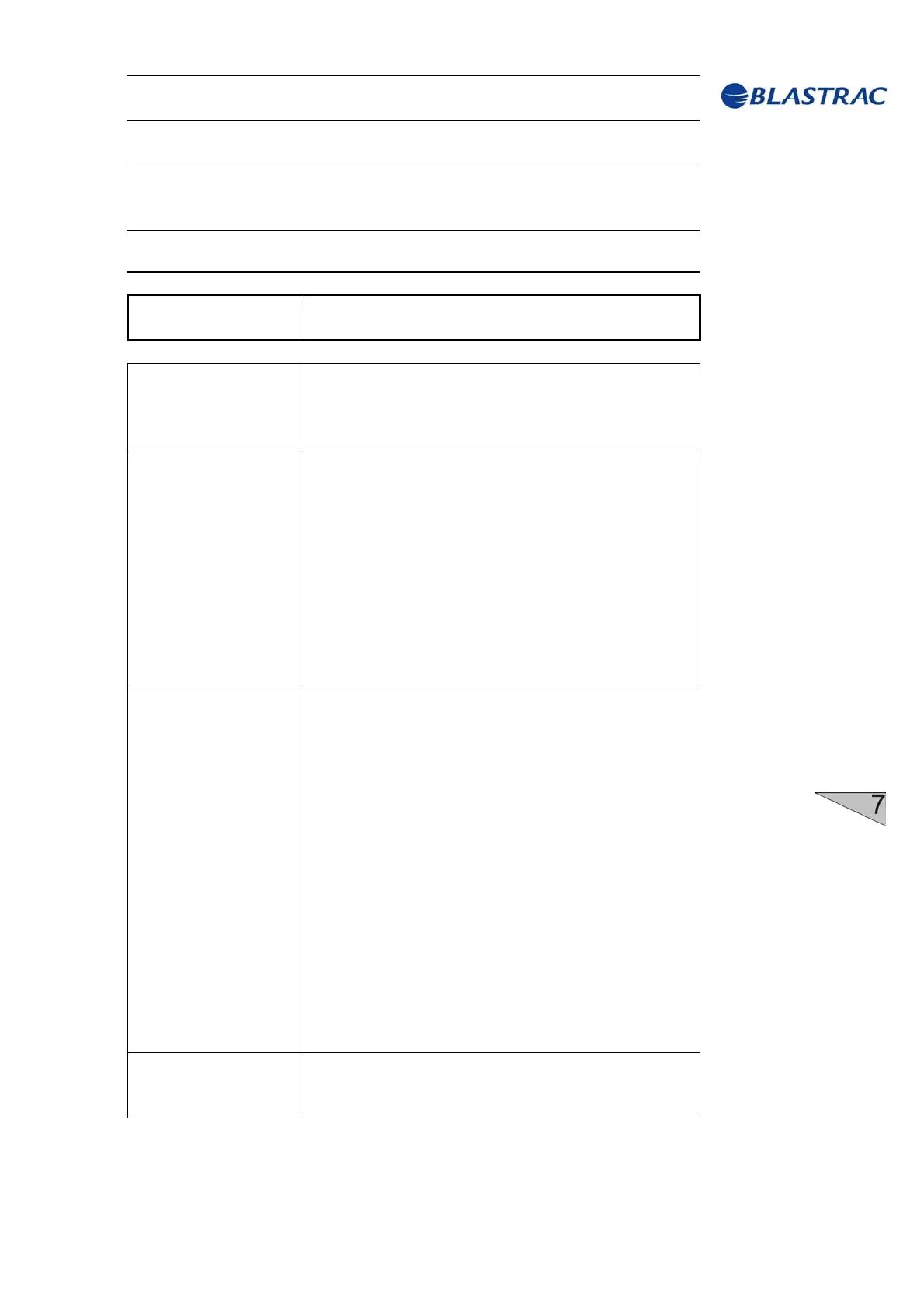

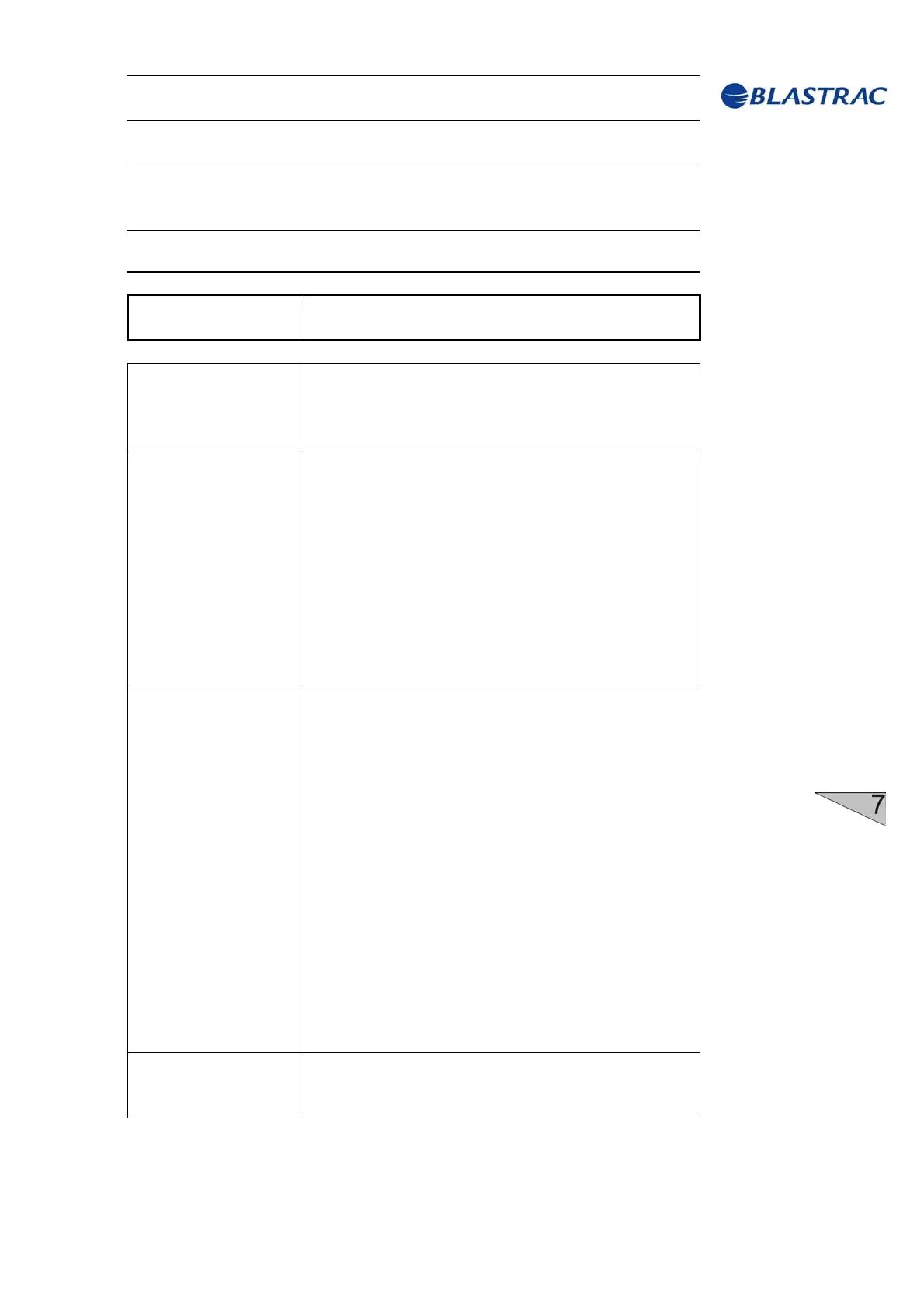

7.2 Maintenance and inspection list

Operating hours/

time period

Inspection points, maintenance

instructions

12 h after repairing

Check the efficiency of all safety devices.

Check all accessible screw connections for

tight seat.

every 3 h Check whether there is any foreign matter in

the hopper, the shot valve housing or in the

blast wheel unit.

Check blast wheel, liners and fasteners for

wear and damage.

Check the seal systems for wear.

Check the electric connections for sediments

of dirt or foreign bodies.

Check the electric motors for dirt and other

contaminants.

daily and prior to

starting work

Check the hose connections for tightness and

fixed seat.

Check the hose to the filter for damages.

Make sure that the dust container of the filter

is emptied. Check blast wheel, liners and

fasteners for wear and damage.

Check the separator parts for wear and

defects. Remove foreign bodies and dust

deposits.

Check the level of abrasive in the storage

hopper. Top up if necessary.

Check all connections of the electric cables

for fixed seat, and check the cables for

damage.

Check the electric motors and connections

for dirt and other contaminants.

annually

Full overhaul and cleaning of the complete

machine.

3

Loading...

Loading...