EBE 350 E Operating Instructions

Maintenance

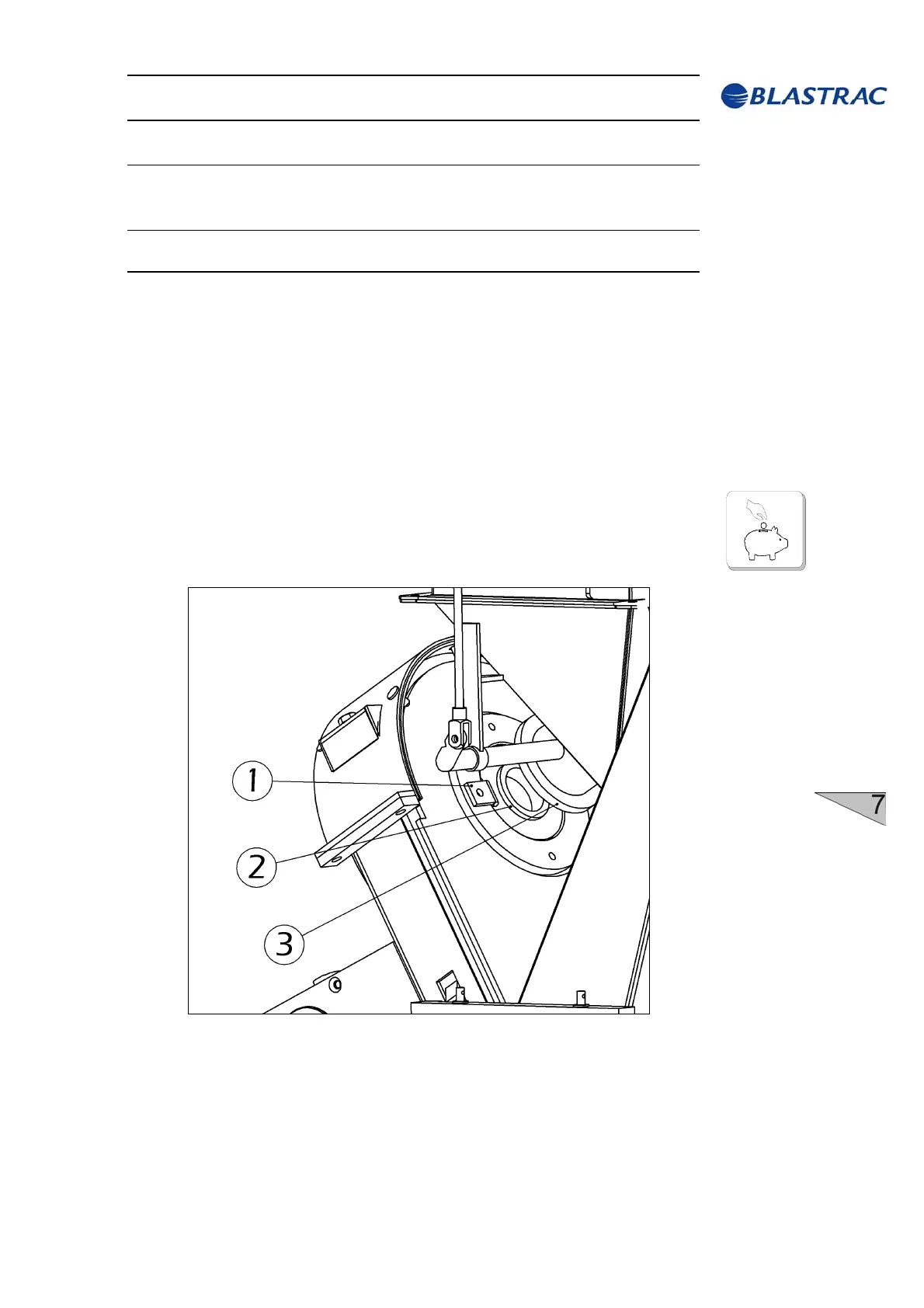

7.4 The blast pattern

Abrasive leaving the blast wheel blades is not thrown in all directions.

Scatter is restricted to an angle of about 80°. This is achieved through

the use of a control cage which surrounds the impeller. The position

of the window in the control cage determines the blast pattern.

Correct adjustment of the control cage and thus of the blast pattern is

the most important factor for optimum working with the EBE 350 E blast

cleaning machine.

Incorrect adjustment of the control cage results in very high wear and

premature blasting-through of the liners in the blast wheel housing, as

well as reduced blasting performance and a possible loss of the

rebounce energy of the abrasive.

Fig. 7.1

1 Cage clamp

2 Control cage

3 Shot valve housing and Feed spout rubber

The adjustment is effected by loosening the cage clamps (pos.1) and

turning of the control cage (pos.2).

5

Loading...

Loading...