21

We reserve the right to make changes without any prior notice. Translation from original instructions

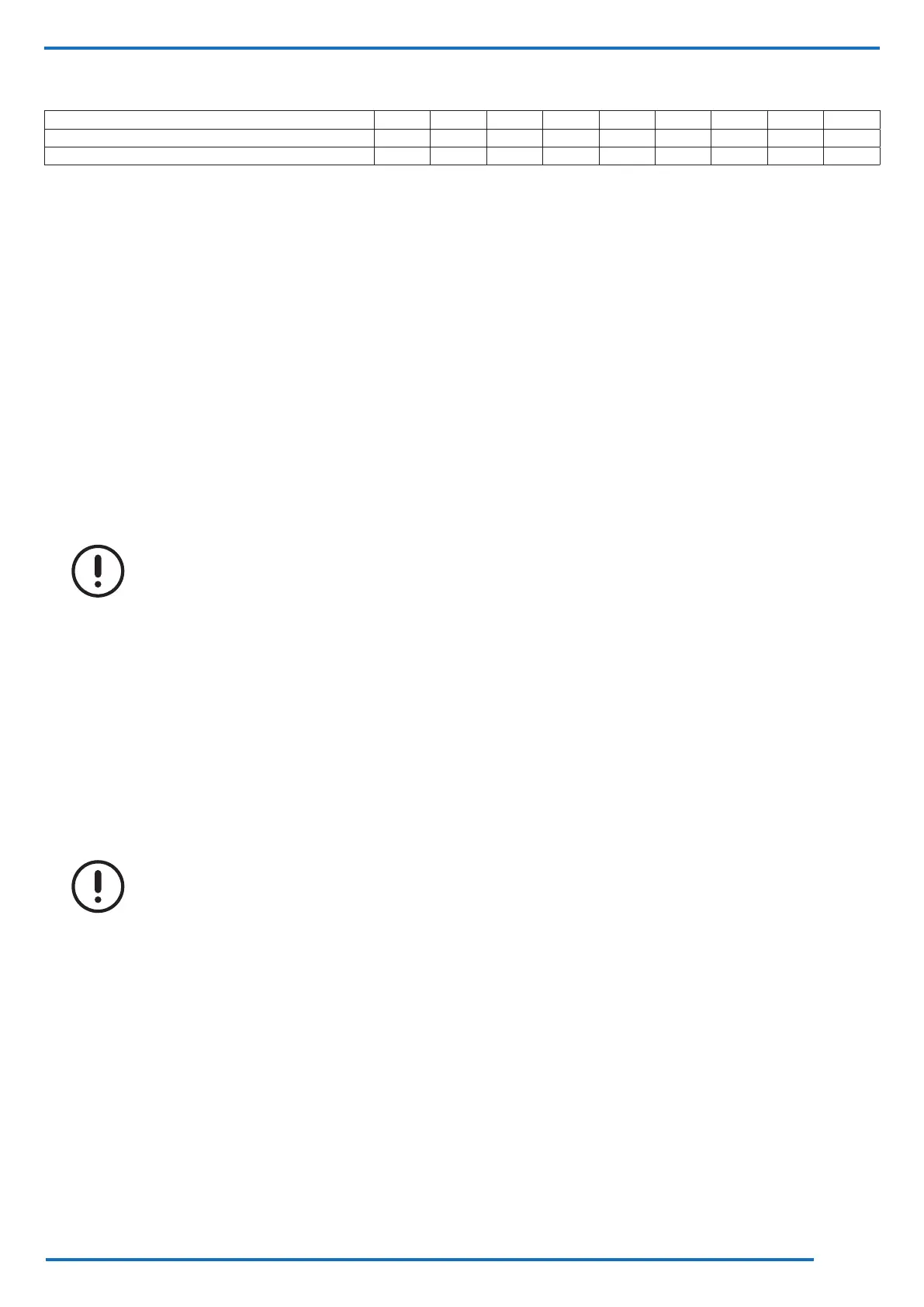

Size SXS XS S S-M M M-L L XL XXL

"K" for units with integrated fans 138 217 350 - 350 - 350 350 350

"K" for units with fans on separate section - - 515 260 350 515 - 515 515

4.7.3 Airowsensor

This device prevents the unit operating in the absence of air ow. The control is effected by a differential pressure switch

which measures the pressure difference upstream and downstream of the evaporator coil and the air lter, or by a differen-

tial pressure transducer in units where EC fans with control of the air ow are present. The going-off of the microprocessor

alarm is delayed by the intervention of the sensor.

To test its operation:

- With AC fans: open the circuit breakers of the fan section and the compressors (QMV and QMC on the wiring diagram),

and then turn on the unit. The microprocessor alarm should appear within a few tens of seconds.

- With EC fans: open the automatic compressor switches (QMC on the wiring diagram), remove the terminal with the

control signal for the EC fan (terminal J4) from the microprocessor card, turn on the unit as above and wait for the alarm.

4.7.4 Dirtyltersensor(optional)

The check of the level of air lter clogging is carried out by means of a differential pressure switch which measures the

upstream and downstream pressure drop of the lter.

The control panel will signal, via an alarm on the display, the need to replace or clean the lter. The machine will continue

to work in any case.

The fouling of the lter may cause a decrease in the ow rate and therefore of the machine’s performan-

ce; restoring the lter as quickly as possible from the time of reporting is recommended.

4.7.5 Dischargeairpressuresensor(optional)

For units with air delivery pressure switch under the raised oor (accessory), once the unit is installed, the installer must

connect the PVC tubes to the air differential pressure transmitter.

The small tubes supplied in coils inside the unit, must be positioned as follows:

- the tube connected to the negative inlet of the air differential pressure transducer should be positioned in the suction

unit, preferably in an intake plenum or in any case in such a position that the air pressure measurement is not inuenced

by the dynamic component;

- the tube connected to the positive inlet of the air differential pressure transducer should be positioned under the oor,

at a sufcient distance from the supply unit in order that the air pressure measurement is not inuenced by the dynamic

component;

The tubes must be positioned taking care not to make any small radius curves and not to choke the

tubes with clamps; incorrect positioning of the ends of the tubes, sharp bends or kinks may cause false

air pressure readings.

Loading...

Loading...