22

We reserve the right to make changes without any prior notice.Translation from original instructions

4.7.6 Airlters

The units are equipped with air lters on the recirculation line with varying degrees of efciency. The lter change must

always take place from the front of the unit.

The lters of the direct expansion units have the same overall size of the evaporator coils, whether they are UNDER or

OVER.

In water chilled units the lters are located on the top (UNDER unit) or behind the front panels (OVER units). In any case

refer to the dimensional drawings.

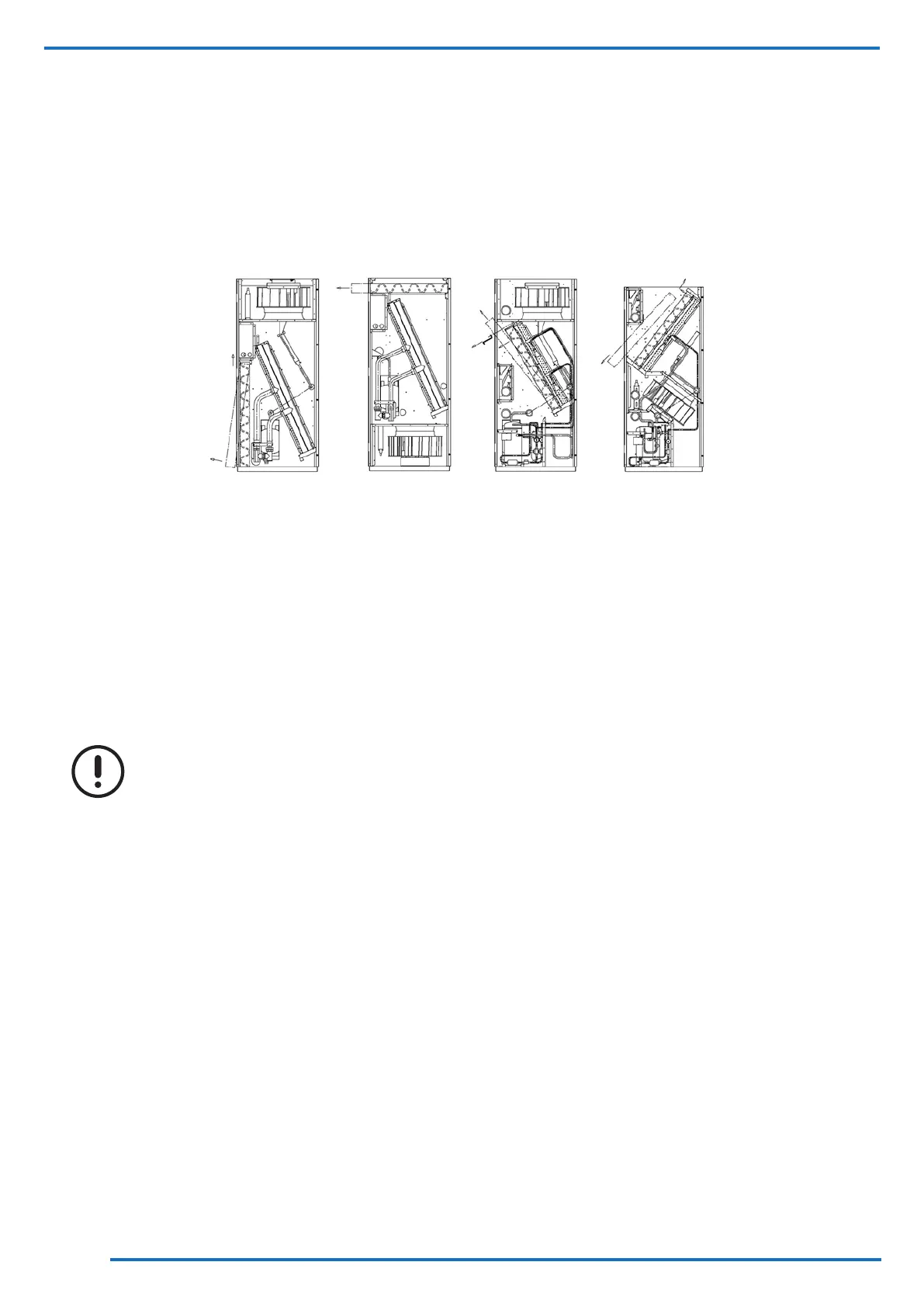

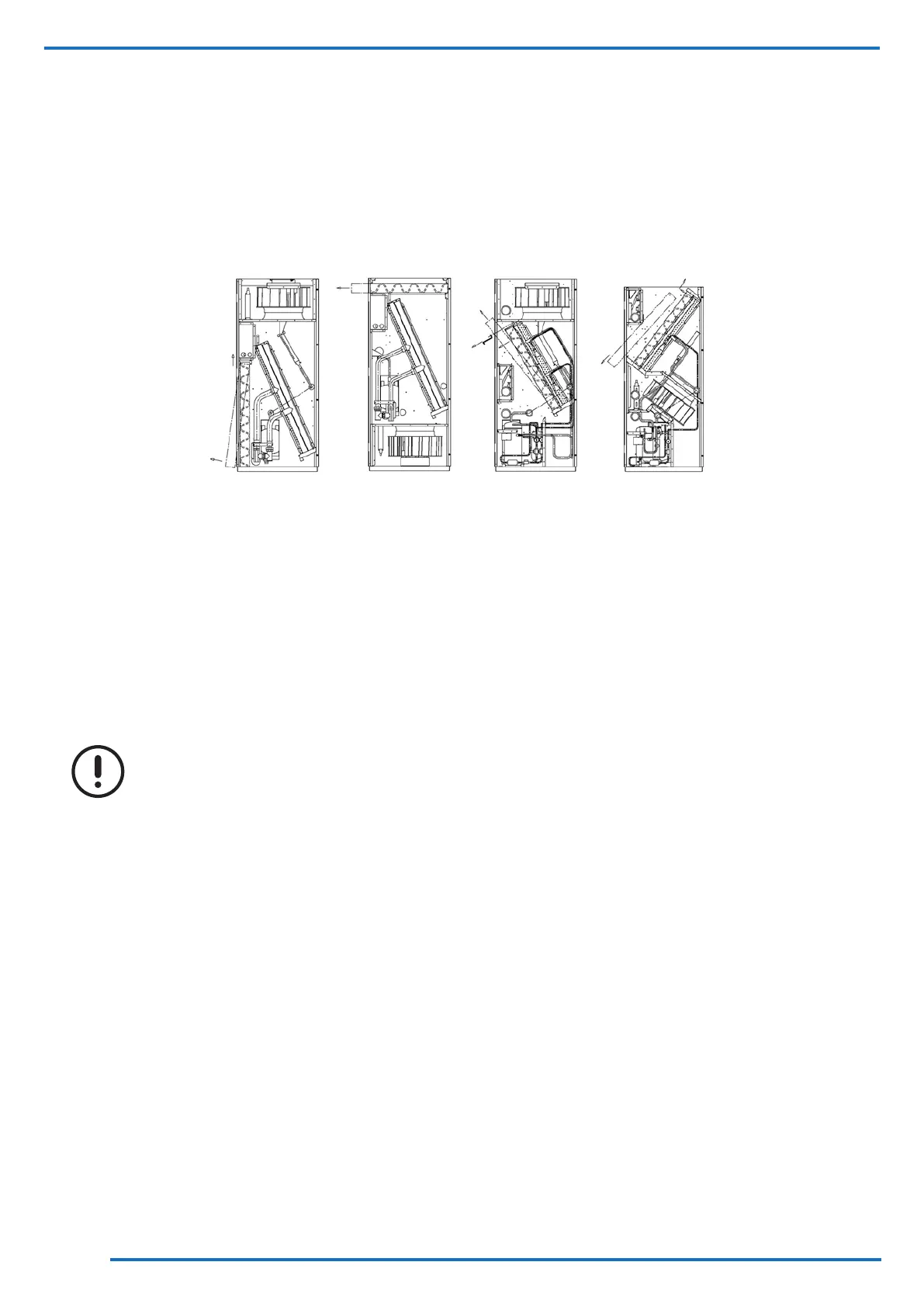

The drawings below show the way to extract the air lters according to the type of unit.

Fig. 5 Extracting the air filters

4.7.7 Humidier

The units can be equipped with an immersed electrode humidier according to the model version. Before use, make sure

all electrical and hydraulic connections have been made.

The humidier is automatically controlled by the microprocessor, which regulates the amount of water present inside the

boiler, according to specic algorithms and according to the request for moisture production. For further details concerning

the operation of the humidier, refer to the humidier and microprocessor manuals.

Should it be necessary to carry out maintenance or replace the humidier components, rst empty the water contained in

the cylinder.

In order to ensure a correct operation and life of the humidier cylinders, the characteristics of the feed water should be

within the limits provided. The limits are reported in the specic manual.

Do not treat with softeners.

The use of well, industrial water or drawn from cooling circuits, potentially chemically or bacteriologically polluted, is forbid-

den. We do not recommend the addition of disinfectants or anticorrosive compounds, as they are potential irritants.

Any particular characteristics of the water supply, such as very low or very high conductivity, may require specic humidier

cylinders which differ from the standard, to be agreed upon with the manufacturer.

Loading...

Loading...