BL6-U Parallel Integrated Controller Quick Commissioning User Manual

49

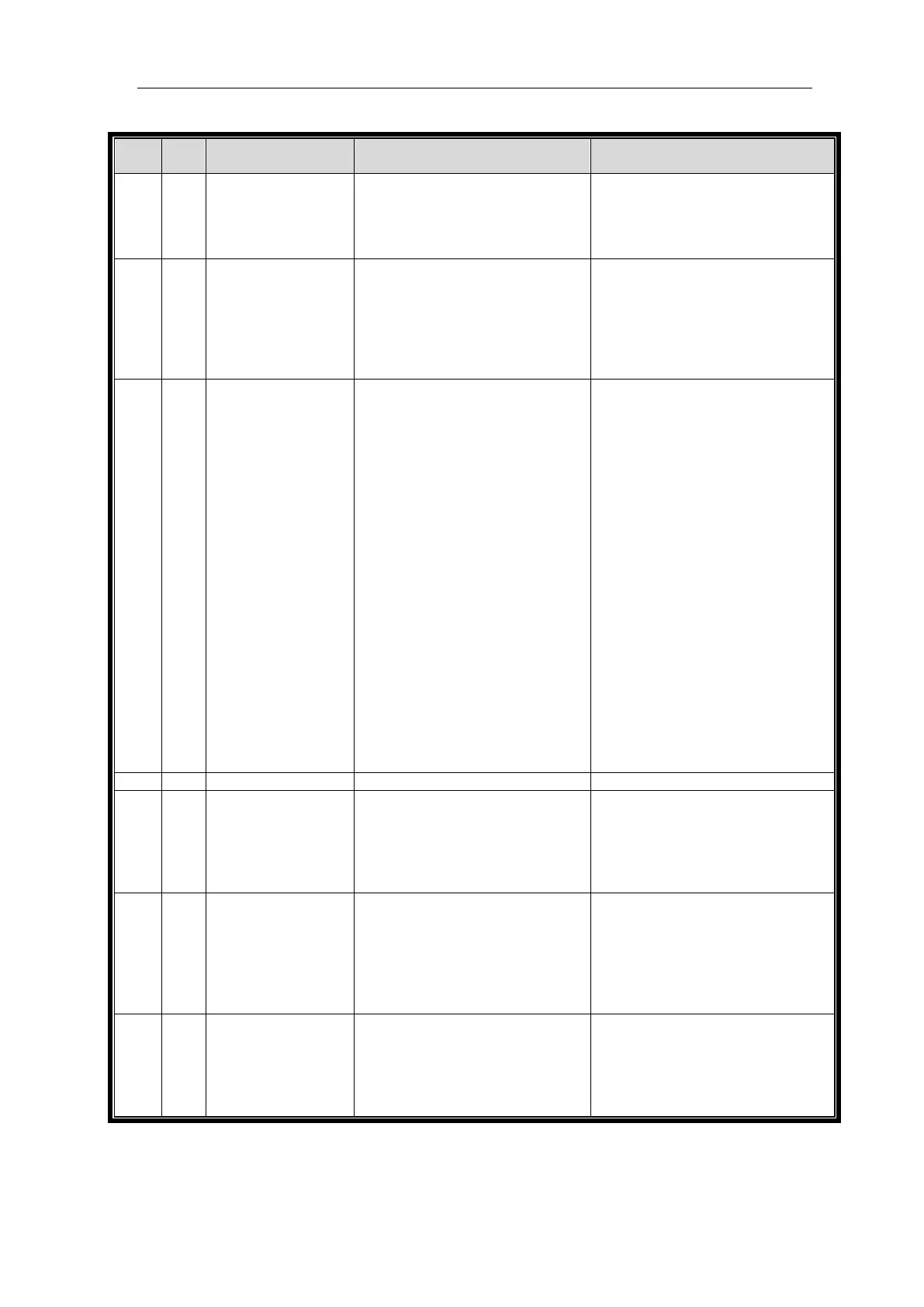

DRIVER FAULT LIST (CONT'D)

Elevator over speed

The speed feedback

exceeds the speed

limit and last longer

than set time.

1. Max speed /last time set

incorrect;

2. Speed over-tuning;

3. Encoder feedback incorrect;

4. Wrong motor parameters setting.

1. Check speed limit setting;

2. Check the P/I parameter;

3. Check encoder;

4. Check motor parameters.

Speed over deviation

The speed deviation

exceeds the allowable

range(F9-03) and last

longer than set time.

1. System overload;

2. Accel/decel time short;

3. Parameter setting wrong;

4. Encoder cannot work properly;

5. Brake wrongly act;

6. Wrong allowable range set.

1. reduce system load;

2. Increase accel/decel time;

3. Check the parameters;

4. Check the encoder;

5. Exchange motor phase sequence or

exchange A+/A- and B+/B- wire;

6. Check brake action.

PG disconnect

Did not receive

encoder signal at

operation.

PG card type setting is

different with actual

one, system cannot

identify it.

1. Encoder wiring is broken, loosen

or wrong connection;

2. Encoder damaged;

3. Wrong PG type setting;

4. PG card damaged;

5. Brake not open.

1. check encoder wiring;

2. Check encoder;

3. Check if F8-02 PG type is same

with actual PG card;

4. Check connection between PG

card and main board;

5. Check if brake can open;

6. If software version is old, please

enter Fault report->Controller Fault, and

find E2, E3 value:

Incremental encoder:

(1)E3=35, no speed feedback;

(2)E2=16, U/V/W signals error;

Sin/Cos encoder:

(1)E3=35, no speed feedback;

(2)E3=29,31,36, abnormal

communication between main board

and SPG card;

(3)E3=28 or 34, C/D signal error;

(4)E3=32 or 33, A/B/C/D signals are

highly similar;

7. If software version is new, these

errors are DF18, DF19 and DF20.

Data fault at saving parameters.

Baseblock circuit error

When system find

baseblock valid and

receive running

command, but running

condition isn’t ready.

1. Wiring for baseblock at X14 is

incorrect;

2. Setting electric level for

baseblock at X14 is incorrect.

1. Check the wiring at X14;

2. Modify the parameters.

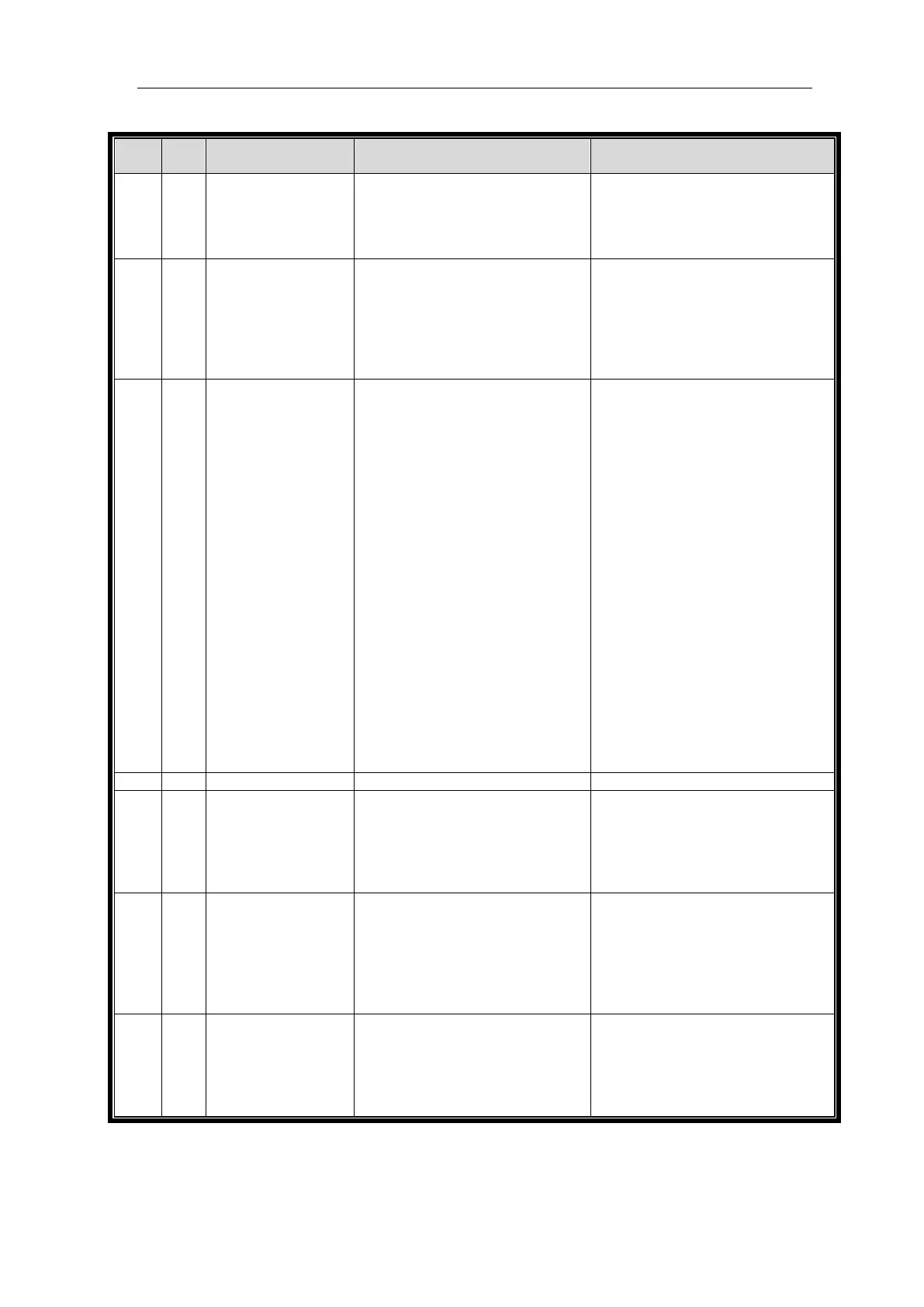

Motor overload

current output exceed

150% (200%) rated

value for 60s (10s).

Motor current exceed

150% (200%) rated

value for 60s (10s).

1. System load too heavy;

2. System power rating too low;

3. Low capacity controller.

1. Reduce system load;

2. Change a more suitable controller;

3. Change motor or increase F5-08

rated current properly to promote

overload capacity.

MC contactor bad

action

Controller main

contactor MC does not

close after given close

command for set time.

1. Wrong wiring for MC contactor;

2. MC contactor damaged;

3. Wrong FX-23 surge feedback

type setting;

4. Drive power on power board is

abnormal.

1. Try to reset the power, if this error

come again, contact supplier for

replacement;

2. Change FX-23 status, then power

off and power on again.

Loading...

Loading...