BL6-U Parallel Integrated Controller Quick Commissioning User Manual

45

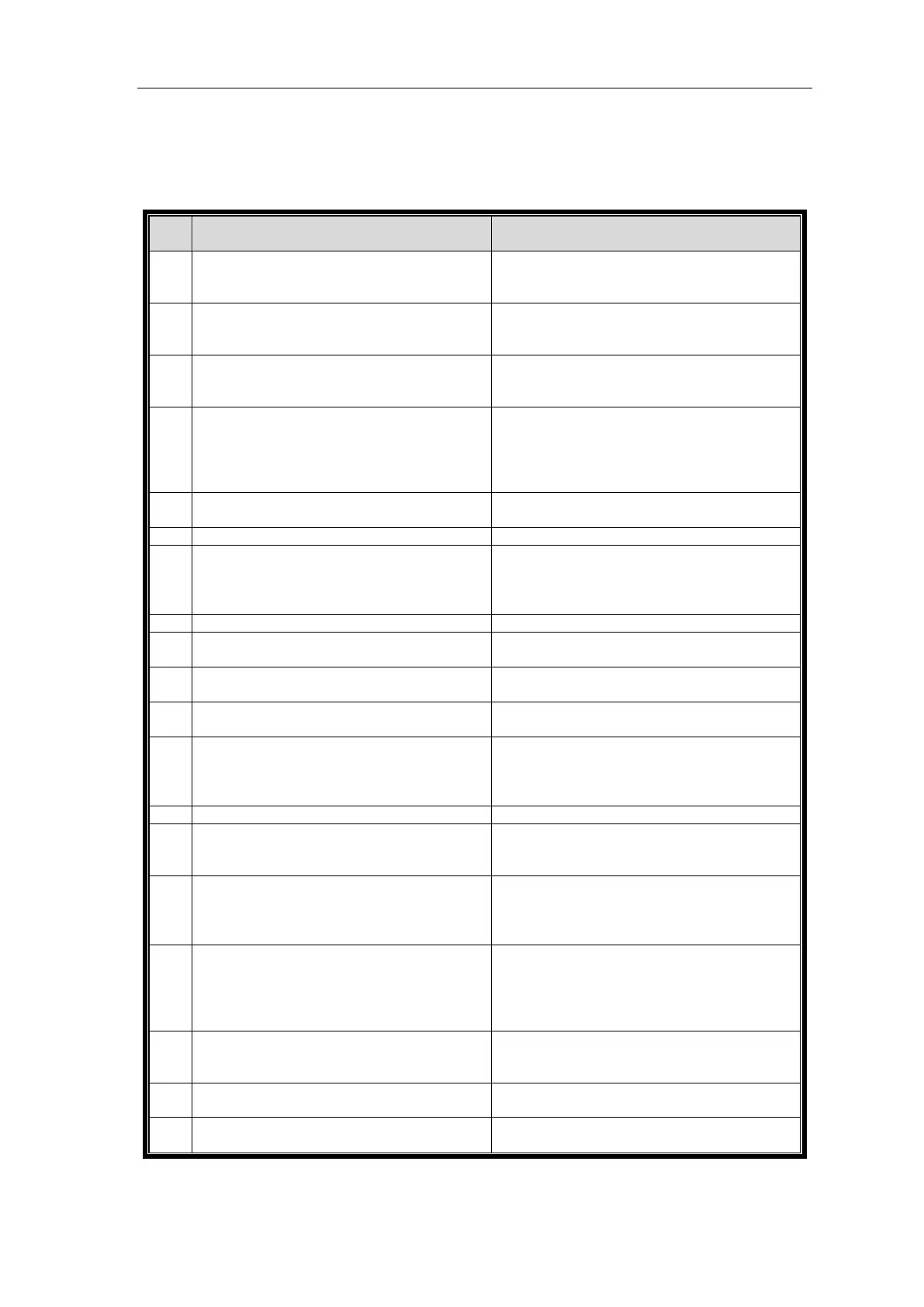

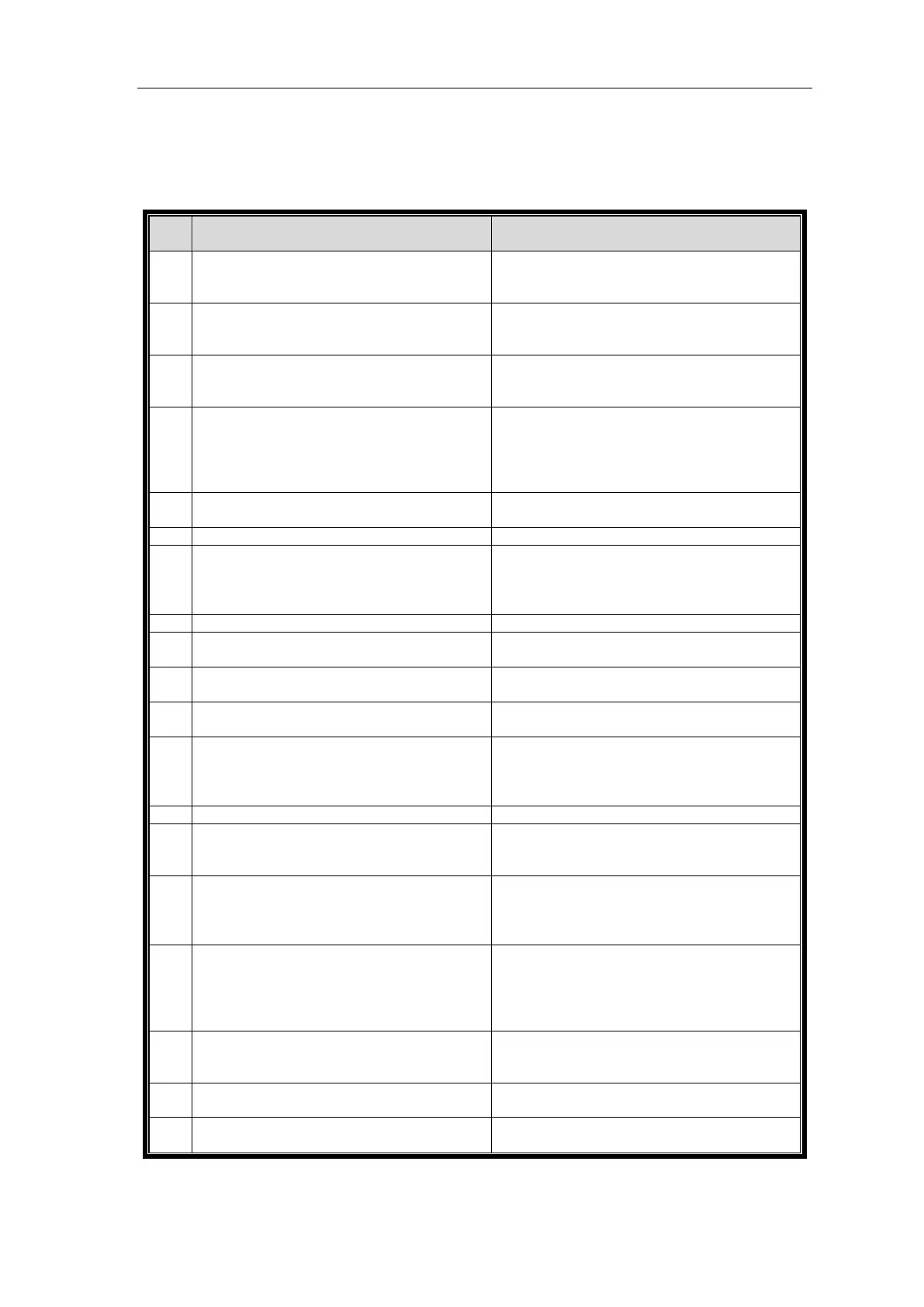

Appendix V Elevator System Faults

Elevator System Fault List

Door inter-lock faults: Door inter-lock circuit open

at elevator running

Check the work condition of door vane and door

interlock circuit. Roller should have enough space at

both side of the vane.

Check drive-error code. Determine the possible

cause of the fault and solve in corresponding

solution.

Elevator running in opposite direction with

command

1. Exchange phase “V” and “W” on motor

2. Exchange phase “A” and “B”, on encoder terminal

block or change in parameter setup.

Brake open fault: System does not receive brake

open feedback signal after output brake open

command:

1. No X6/X31 feedback after Y0output 0.5/2s.

2. X6/X31 enable when Y0 has no output.

1. Check the traction machine brake detection

switch and wiring;

2. If no feedback switch, should set feedback enable

to OFF

During elevator running, leveling zone input

signal X3, X4 is always on.

Check leveling zone signal circuit and induction

switch

Inverter pulse not enough at elevator running.

Check the wiring from encoder to controller.

KDY fault: Contactor KDY output not matching

feedback signal:

1. After Y1 output X5 no feedback in 0.4s.

2. X5 is enabled when Y1 has no output.

Check the contactor KDY coil and output/feedback

circuit wiring.

Safety circuit open, input X10 is invalid.

Check all safety circuits.

Leveling switch signal missing: Elevator is running

pass the floor, but there is not input at X3 /X4.

Check the leveling switches and its wiring.

Elevator pass top limit switch (X1 is invalid)

Check encoder, top limit switch including its

position / wiring.

Elevator pass bottom limit switch (X2 is invalid)

Check encoder, bottom limit switch including its

position / wiring.

Floor counter error from encoder deviation

accumulation: after this error, elevator will return

to bottom floor in inspection speed for

recalibration.

1. Check encoder wiring and related circuits;

2. Check the leveling switch and related circuits;

3. Possible reason: traction rope slip /door drive

shake at start.

No drive output after running command.

Check parameters in controller or contact supplier.

Floor number error: after this error, elevator will

return to bottom floor in inspection speed for

recalibration.

Check the encoder and its wiring.

The deceleration distance for target floor is not

enough, elevator did not perform hoistway

parameter learning after changing terminal

switch location.

1. Decrease “Least Speed” in user menu; make

elevator running curve steeper; reduce speed

adjusting distance;

2. Do hoistway parameter learning again.

When elevator reaches top/bottom floor and get

deceleration instruction, but elevator doesn’t

slow down; elevator did not perform hoistway

parameter learning after changing terminal

switch location.

1. Increase the proportion parameter of controller;

Check the braking resistor specification;

2. Make elevator running curve smoother;

3. Do hoistway parameter self-learning.

Single running time is over set time

1. Check related parameters in controller;

2. Check the traction rope for slip or car jam;

3. Check value of parameter “Over Time”.

Elevator has inspection signal input (X0 invalid) at

elevator normal running.

Check inspection switch and related circuits.

One of two leveling switch (X3, X4) is invalid at

elevator normal running.

Check leveling switches and wirings.

Loading...

Loading...