-8-

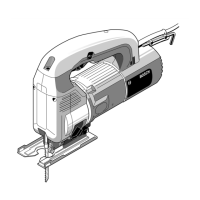

FOOTPLATE ANGLE ADJUSTMENT

The footplate may be tilted to allow angle cuts

up to 45˚ in either direction. To adjust

footplate, loosen screw with allen wrench, slide

the footplate towards the front of the tool, and

rotate to the desired angle, as marked on the

angle scale. Detent slots will hold the footplate

firmly at 45˚, and there are additional position

marks for 15˚ and 30˚ angles. Intermediate

angles may be set with a protractor. After

positioning the footplate, securely tighten

screw).

ANTI-SPLINTER INSERT

To minimize splintering of the top surface of

the material being cut, place the anti-splinter

insert in the blade opening of the footplate.

Note: This insert will only work with blades

that have ground sides such as T301CD,

T101B, T101D, and T101DP.

DETENT SLOTS

ANGLE

SCALE

SCREW

FOOTPLATE

PROTRACTOR

(Not included)

The following types of blades should only be

used with orbital Setting O:

1. Blades with teeth that point downward

(reverse-tooth blades).

2. Blades with teeth that point straight out

rather than up or down.

3. Carbide-tipped blades.

4. Grit-edge blades.

Loading...

Loading...