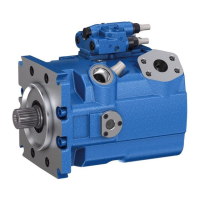

The document describes the Axial Piston Variable Pump A7VO, Series 63, manufactured by Bosch Rexroth. This instruction manual (RE 92202-01-B/08.2012) provides comprehensive information for machine/system manufacturers, fitters, and service technicians regarding the safe and appropriate transport, installation, commissioning, operation, maintenance, removal, and basic troubleshooting of the axial piston unit.

Function Description:

The A7VO is a variable pump with an axial tapered piston rotary group in a bent-axis design, specifically engineered for hydrostatic drives in open circuits. Its primary function is to generate, control, and regulate a hydraulic-fluid flow. The flow rate is directly proportional to the drive speed and displacement. A key feature is the stepless adjustment of the flow by changing the bent axis angle. In this design, pistons are arranged at an angle to the drive shaft, and with each revolution, they execute a stroke in the cylinder bores, the size of which depends on the swivel angle (pitch) of the bent-axis rotary group. Hydraulic fluid is fed into and out of the piston chamber through two kidney-shaped control slots in the lens plate. Increasing the swivel angle increases displacement, while reducing it decreases displacement. The swivel angle is hydraulically controlled by a stroke piston. When non-pressurized, the pump swivels to its maximum displacement position (Vg max) by a return spring, depending on the control unit. In an open circuit, hydraulic fluid flows from the reservoir to the pump, then to the consumer (e.g., hydraulic motor), and directly back to the reservoir. For prolonged zero-stroke operation (> 1 min), bearing flushing via port U is recommended.

Important Technical Specifications:

The technical data, operating conditions, and performance limits for the A7VO Series 63 (sizes 28 to 160 and 250 to 500) are detailed in data sheets RE 92202 and RE 92203.

Key specifications include:

- Cleanliness Level: For functional reliability, the hydraulic fluid requires a cleanliness level of 20/18/15 according to ISO 4406. At very high temperatures (+90 °C to +115 °C), a cleanliness level of at least 19/17/14 is necessary.

- Suction Pressure: A minimum suction pressure of 0.8 bar absolute at port S is required during operation for all installation positions and maximum swivel angle.

- Case Drain Pressure: Maximum case drain pressure at ports R1 or R2 must be observed.

- Hydraulic Fluid: Approved mineral-oil based, environmentally acceptable, and fire-resistant (HFDU/HFDR) hydraulic fluids are specified in data sheets RE 90220, RE 90221, and RE 90222.

- Operating Temperature: Permissible and optimal viscosity ranges are provided in data sheets RE 92202 and RE 92203.

- Port Connections: The manual provides detailed tables (Table 11 and 12) for ports, including designation, function, standard, maximum pressure, and connection state (must be connected or plugged). For instance, service lines (A/B) have a maximum pressure of 400 bar, while suction lines (S) are rated for 3 or 7 bar (for high-speed versions).

- Bearing Types: The A7VO uses standard bearings, while the A7VLO uses long-life bearings, available for sizes 250 to 500. Long-life bearings can be retrofitted.

- Weights: The weights of the axial piston units range from 17 kg (size 28) to 234 kg (size 500).

Usage Features:

- Intended Use: The axial piston unit is exclusively approved as a pump for hydrostatic drives in open circuits and is intended for professional use, not private use. It must only be commissioned after being installed in a machine/system and after the safety of the entire system has been established according to the machine directive.

- Installation Positions: Various installation positions are permissible, including below-reservoir and above-reservoir installations, with specific guidelines for each, especially concerning minimum fluid levels, immersion depths, and distances between suction and case drain lines.

- Direction of Rotation: The direction of rotation (clockwise or counter-clockwise) is specified on the name plate and must match the output/input shaft of the machine/system.

- Mounting: The unit can be installed with a coupling or on a gearbox. Specific instructions are provided for each method, including torque specifications for bolted joints (VDI 2230).

- Electrical Connection: Detailed instructions for connecting electrical components are provided, emphasizing correct polarity, permissible voltage range, and recommended control units.

- Commissioning: First commissioning involves filling and air bleeding the unit with a suitable filter system (10 µm filter grade), testing the hydraulic fluid supply, and performing a functional test according to the machine/system manufacturer's instructions.

- Safety: The manual highlights critical safety instructions, including warnings about high pressure, suspended loads, hot surfaces, and improper routing of cables. It also emphasizes the importance of qualified personnel for all activities.

Maintenance Features:

- Inspection: Regular inspections are crucial for long-term reliability. This includes daily checks of hydraulic fluid level and operating temperature, weekly checks of operating temperature at the reservoir, and yearly or every 2000 operating hours checks of the optionally fitted filter in the pressure line of the boost pump.

- Cleaning: The unit should be cleaned with water and mild detergents, avoiding solvents or aggressive cleaners. Power washers should not be pointed at sensitive components.

- Maintenance Schedule: The service life of the axial piston unit's bearings is limited. The hydraulic fluid should be changed at least once per year or every 2000 operating hours (whichever comes first).

- Repair and Spare Parts: Only original Rexroth accessories and spare parts should be used. Unauthorized modifications or use of non-specified components will void the warranty. Contact Bosch Rexroth Service for repairs and spare parts.

- Storage and Preservation: Detailed instructions are provided for storing axial piston units, including ambient conditions, corrosion protection, and preservation methods for different storage durations (up to 24 months).

- Troubleshooting: A comprehensive malfunction table is included, listing possible causes and remedies for common issues like unusual noises, insufficient flow, pressure/flow fluctuations, excessive hydraulic fluid temperature, and instability/vibrations.

- Disposal: Guidelines for environmentally responsible disposal of the axial piston unit, hydraulic fluid, and packaging material are provided, emphasizing adherence to national regulations and separation of materials (cast parts, steel, aluminum, non-ferrous metal, electronic waste, plastic, seals).