Do you have a question about the Bosch Rexroth RE 90300-B and is the answer not in the manual?

Information on the validity of the documentation for specific products and target audience.

Lists essential and recommended documents for product commissioning and use.

Explains symbols, signal words, and designations used for clear communication.

Defines the specific applications and intended use of axial piston units.

Lists foreseeable forms of faulty usage considered improper and associated liabilities.

Outlines the required knowledge and skills for safe operation and maintenance.

Provides overarching safety guidelines applicable to all operations.

Details safety warnings specific to axial piston units and their operation.

Emphasizes the user's responsibility for providing and using PPE.

Warns about improper handling that can lead to product damage.

Highlights risks associated with insufficient hydraulic fluid and lubrication.

Warns against mixing hydraulic fluids due to potential product damage.

Stresses the importance of hydraulic fluid cleanliness for component longevity.

Details risks of improper cleaning methods and agents.

Addresses environmental concerns related to product and fluid disposal.

Warns about chemical/corrosive environments damaging the product.

Covers risks of environmental pollution from hydraulic fluid leaks.

Warns about heat-generating components damaging nearby parts.

Lists included parts and optional accessories delivered with the unit.

Explains the basic functions of axial piston pumps and motors.

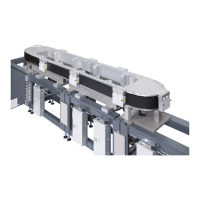

Outlines the categories and features of the axial piston unit product range.

Details how to identify the axial piston unit using its name plate.

Covers various methods for transporting the axial piston unit safely.

Specifies requirements for proper storage to maintain unit integrity.

Steps for unpacking and required installation conditions.

Discusses permissible installation positions and their implications.

Covers preparation, dimensions, general instructions, and connection methods.

Steps for completing assembly, hydraulic, and electrical connections.

Recommends a flushing cycle before commissioning to remove contaminants.

Covers initial setup, filling, testing, and functional checks for the unit.

Explains the running-in process and its importance for component longevity.

Procedures for recommissioning the unit after a period of inactivity.

Notes that operation requires no settings and users should stay within performance limits.

Instructions for cleaning and maintaining the axial piston unit.

Recommends regular inspections of the hydraulic system and unit.

Outlines maintenance requirements, focusing on hydraulic fluid quality.

Details on how and where repairs should be performed.

Information on obtaining and using original spare parts.

Steps to take before removing the axial piston unit.

Step-by-step procedure for removing the axial piston unit.

Guidance on preparing removed components for storage.

Instructions for environmentally responsible disposal of the unit and its fluids.

Warns against modifications and explains warranty implications.

A systematic approach to diagnosing and resolving issues.

A table listing common pump malfunctions, causes, and remedies.

A table listing common motor malfunctions, causes, and remedies.

Directs users to product-specific data sheets and online catalogs for technical data.

Lists product types and links to their specific instruction manuals.

| Brand | Bosch |

|---|---|

| Model | Rexroth RE 90300-B |

| Category | Industrial Equipment |

| Language | English |