English | 13

(15)

Hex key

b)

a)

Accessories shown or described are not included with the

product as standard. You can find the complete selection of

accessories in our accessories range.

b)

Commercially available (not included in the scope of deliv-

ery)

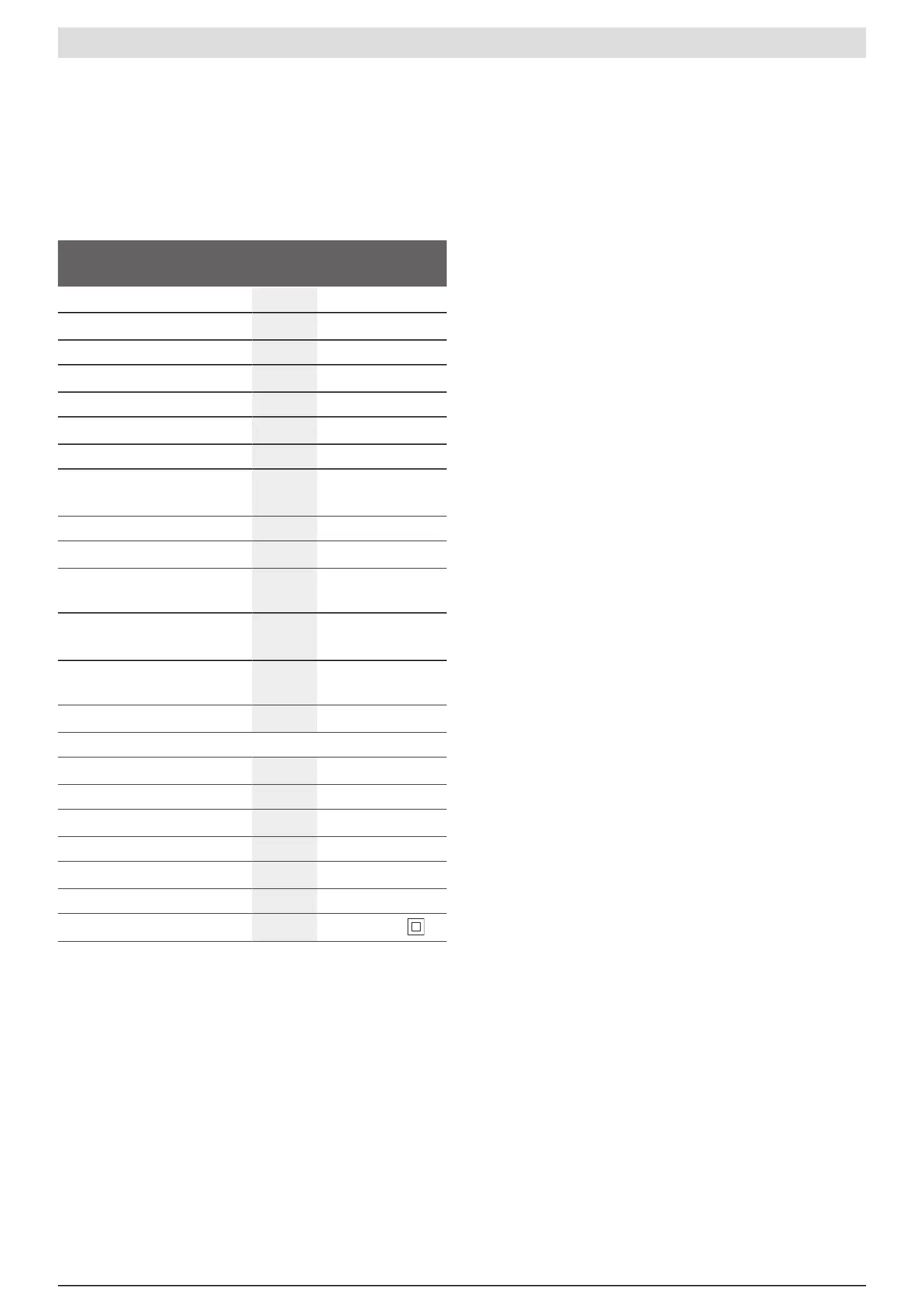

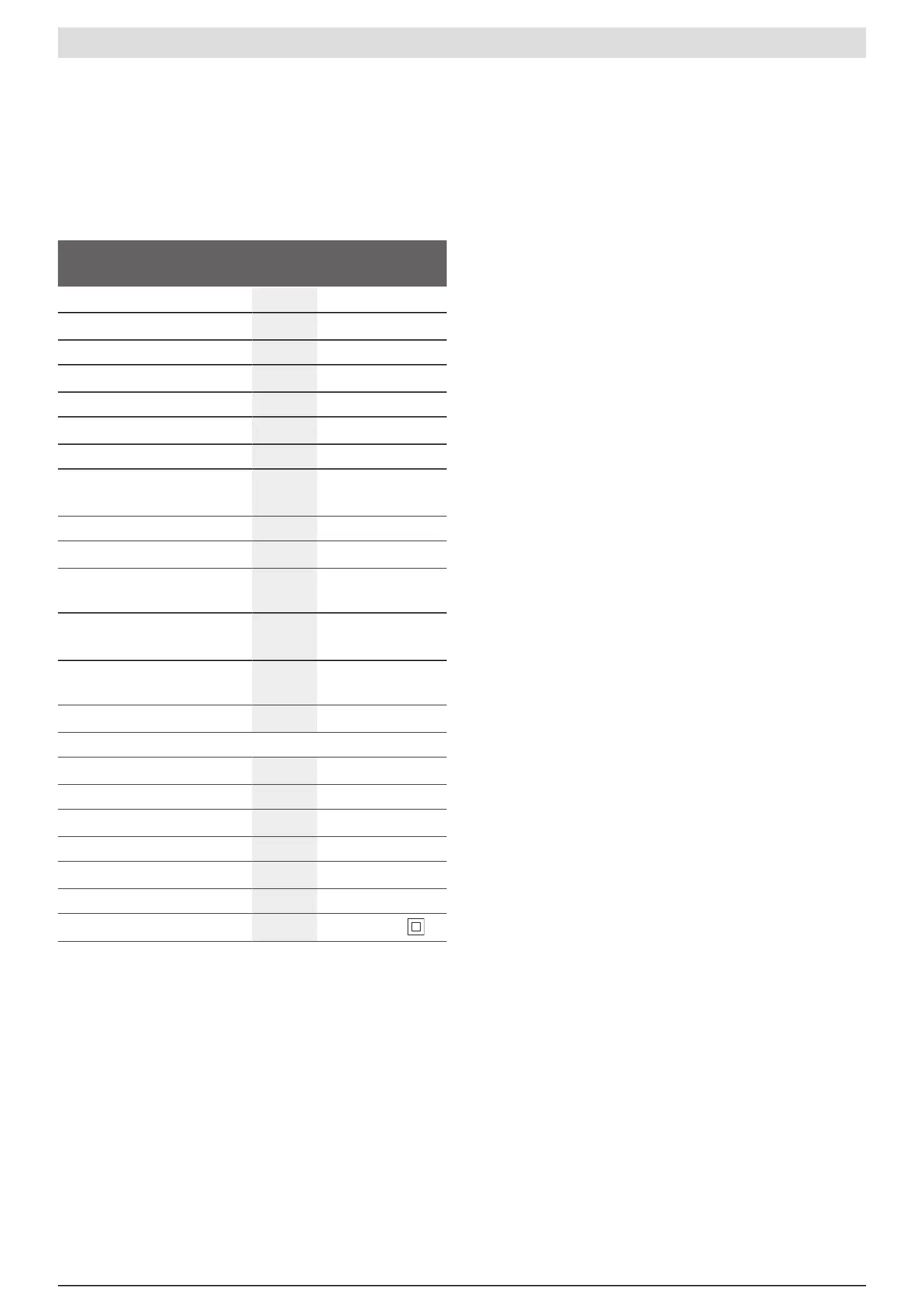

Technical Data

Impact Drill UniversalImpact

800 | 8000

Article number

3 603 A31 1..

Rated power input W 800

Max. power output W 560

No-load speed min

-1

50–3100

Rated speed min

-1

50–3100

Impact rate min

-1

46,500

Rated torque Nm 1.45

Stall torque in accordance

with EN 62841

Nm 19

Speed preselection ●

Constant electronic control ●

Clockwise/anticlockwise ro-

tation

●

Rapid Shut-Off (KickBack

Control)

●

Fully automatic spindle lock

(Auto-Lock)

●

Spindle collar diameter mm 43

Max. drilling diameter

– Masonry mm 14

– Concrete mm 14

– Steel mm 12

– Wood mm 30

Chuck capacity mm 2–13

Weight

A)

kg 1.7

Protection class

/ II

A) Weight without mains connection cable and without mains plug

The specifications apply to a rated voltage [U] of 230 V. These spe-

cifications may vary at different voltages and in country-specific mod-

els.

Noise/vibration information

Noise emission values determined according

toEN62841-2-1.

Typically, the A-weighted noise level of the power tool is:

Sound pressure level103dB(A); sound power

level111dB(A). Uncertainty K=5dB.

Wear hearing protection!

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to EN62841-2-1:

Drilling into metal: a

h

=8 m/s

2

, K=2 m/s

2

,

Impact drilling into concrete: a

h

=32 m/s

2

, K=2.5 m/s

2

,

Screwdriving: a

h

< 2.5 m/s

2

, K=1.5 m/s

2

.

The vibration level and noise emission value given in these

instructions have been measured in accordance with a

standardised measuring procedure and may be used to com-

pare power tools. They may also be used for a preliminary

estimation of vibration and noise emissions.

The stated vibration level and noise emission value repres-

ent the main applications of the power tool. However, if the

power tool is used for other applications, with different ac-

cessories or is poorly maintained, the vibration level and

noise emission value may differ. This may significantly in-

crease the vibration and noise emissions over the total work-

ing period.

To estimate vibration and noise emissions accurately, the

times when the tool is switched off or when it is running but

not actually being used should also be taken into account.

This may significantly reduce vibration and noise emissions

over the total working period.

Implement additional safety measures to protect the oper-

ator from the effects of vibration, such as servicing the

power tool and accessories, keeping their hands warm, and

organising workflows correctly.

Assembly

u Pull the plug out of the socket before carrying out any

work on the power tool.

Auxiliary Handle (seefigureA)

u Before carrying out any work, make sure that the wing

bolt is tightened. Loss of control can cause personal in-

jury.

u Do not operate your power tool without the auxiliary

handle (10).

Turn the wing bolt (7) anti-clockwise and guide the auxiliary

handle (8) in the required position over the drill chuck onto

the spindle collar of the power tool.

You can swivel the auxiliary handle (10) in order to achieve a

safe work posture that minimises your fatigue.

Swivel the auxiliary handle (10) to the required position and

retighten the wing bolt (7) in clockwise direction.

Setting the Drilling Depth (seefigureB)

You can use the depth stop to set the required drilling depth

X.

Press the button for depth stop adjustment (11) and insert

the depth stop into the auxiliary handle (8).

The fluting on the depth stop (12) must face downwards.

Pull the depth stop(12) far enough out that the distance

between the drill bit tip and the edge of the depth stop(12)

corresponds to the required drilling depth X.

Dust/chip extraction

The dust from materials such as lead paint, some types of

wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reac-

Bosch Power Tools 1 609 92A 9ED | (29.02.2024)

Loading...

Loading...