Commissioning

6 720 808 928 (2017/06)38

6.8 Integral heat meter (if fitted)

The heat meter complies with the requirements of the European

Directive MID 2004/22/EC modules B and D and of the standard EN

1434 class 2.

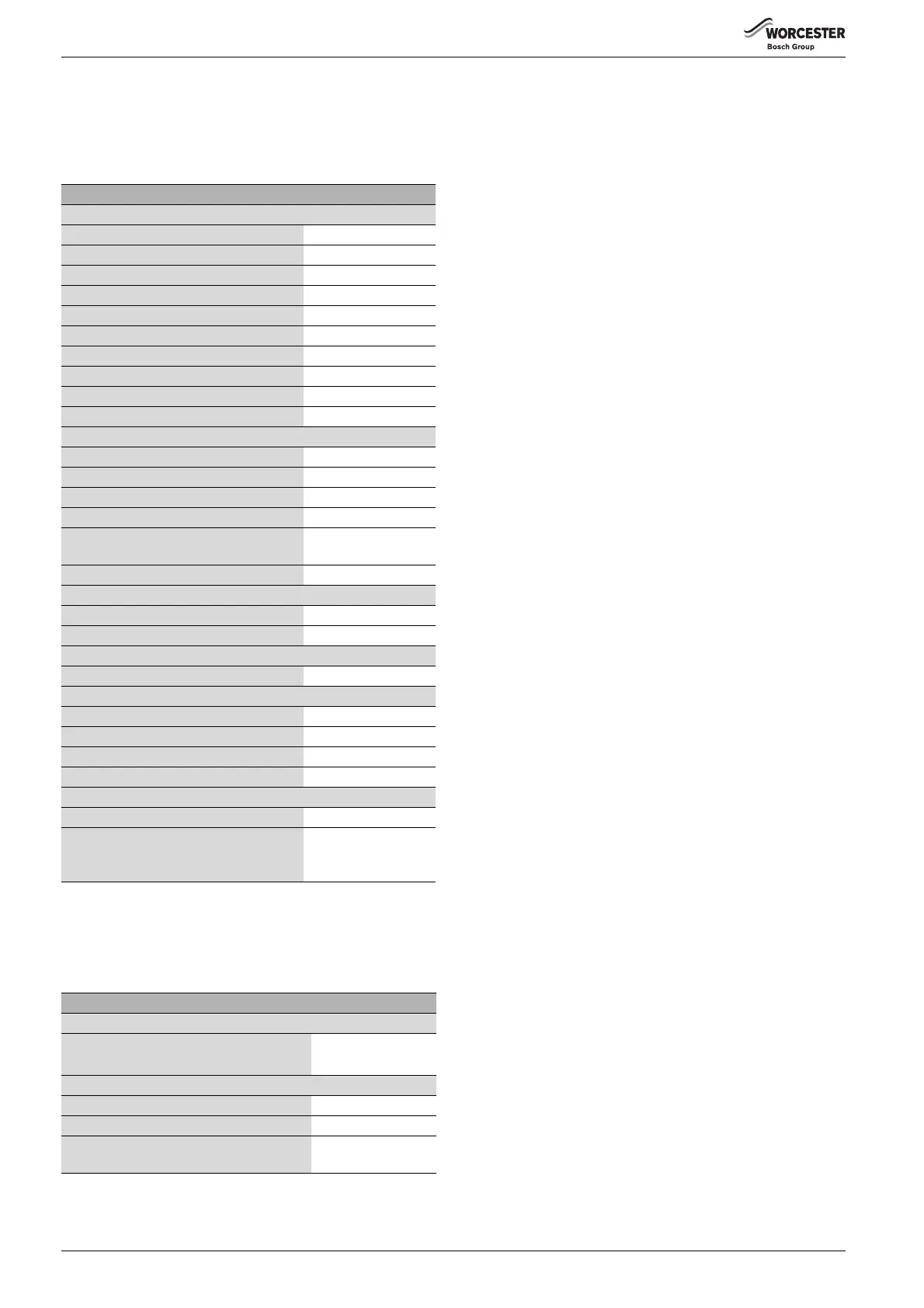

Technical data

The heat meter is designed on the basis of the proven fluid oscillation

principle. Due to the use of a static flow sensor, the heat meter does not

have any moving parts and thus no wear. The fluid oscillation principle

guarantees a high stability and repeatability for a reliable and precise

measurement of flow and thermal energy.

The heat meter consists of a static fluid oscillator flow sensor for flows

from qp 0.6 - 2.5 m

3

/h, in permanent connection with a removable

integrator and a pair of temperature sensors covering an operation

range from 5 °C - 90 °C.

Main features

The heat meter optimized for the measurement and calculation of energy

consumption in district or local heating systems.

• Complies with the requirements of the European Directive MID

2004/22/EC modules B and D and of the standard EN 1434 class 2.

• Flow of qp 0.6 - 2.5 m

3

/h.

• Corrosion resistant materials.

• No moving parts, thus no wear.

• Not sensitive to dirt.

•Stable.

• Direct pick-up of voltage pulses without reflectors.

• Long-term stability, accurate and reliable measurement.

• Easy to operate and read.

• Non-volatile EEPROM memory.

• 18 monthly energy values for heat energy, volume and for the set day

values.

• Self-monitoring of conditions.

Functions

• Recording heat consumption by means of measuring the flow and

temperature difference.

• Displaying consumption data:

– 18 monthly energy and volume values.

– Set day values.

– Operating data.

– Self-monitoring with error display.

Energy calculation

The flow sensor records the flow. Using a microprocessor, the integrator

calculates the temperature difference and calculates the thermal

energy, respectively the heating energy, consumed using the average

flow and the heat coefficient.

Monthly values

At the end of each month, the monthly values are stored. A total of 18

monthly values of heat energy are volume are memorized in the

integrator.

Powered remote M-Bus

The powered remote M-Bus communication interface is a serial interface

which permits communication between different M-Bus devices via a

central M-Bus station.

The M-Bus protocol is compliant with standard EN1434-3.

By default, the primary address will be configured with the address 0

and the secondary address will correspond to the serial number of the

heat meter.

Technical data for the M-bus communication system:

M-Bus protocol compliant with standard EN 1434-3; free potential

interfacing without polarity (the voltage measured on the last device

must exceed 36VDC); transmission speed 300/2400 Baud; variable

data structure.

Type of cable recommended: telephone cable JYStY N*2*0.8 mm

2

.

integrator

Temperature sensors

Temperature sensor 2 wires Pt1’000

Diameter Ø 5.0; Ø 5.2, Ø 6.0 mm

Cables length 1.5 m

Admissible range 0...110 °C

Differential range 3...75 °C

Response limit 0.5 K

Temperature resolution (display) 0.1 K

Temperature resolution Δt 0.01 K

Measurement cycle for temperature from 10 seconds

Measurement cycle for flow

1)

1) the oscillating measurement principle and the differential pressure piezo sensor

ensures at any time that all pulses, ie, all volume is detected. In contrary to the

ultsasonic measuring principle, no scanning with a signal through the water is

necessary.

Permanently

Environment class

Environment class C

Mechanics M1

Electronics E1

Battery protection class III

Cable connection between flow sensor and

integrator

0.6 m, fix

Protection index IP 65

Permissible temperature

Operation 5...55 °C

Storage and transport -10...60 °C

Display

Display 8-digits LCD

Display units

Energy kWh, MWh, MJ, GJ

Volume m

3

Temperature °C

Δ temperature K

Power supply

Lithium battery 3V 6+1 or 12+1 years

Powered by M-Bus line 1 device = 2 M-Bus

charges

(max 2 x 1.5mA)

Table 27

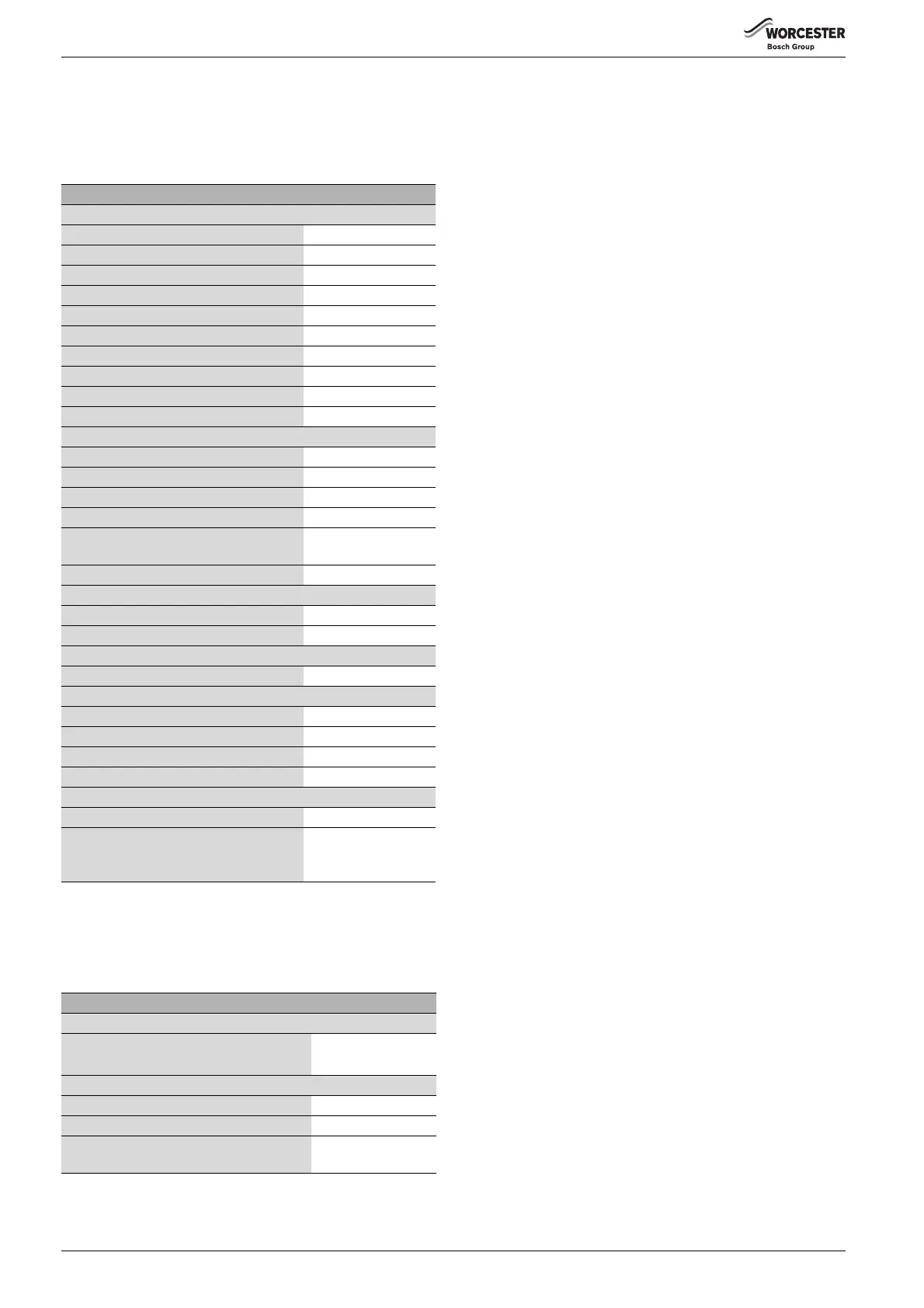

Integrator pulse output option with accessary only

Pulse output

Open drain (MOS Transistor)

Vcc

max

: 35 V

DC

; ICC

max

: 25mA

1 Hz, 500 ms

Pulse inputs with a dry contact

Power supply internal 2.3 V

DC

R

pull UP internal

2 M Ω

Pulse factor 0...999.999 m

3

/Imp

or without unit

Table 28

Loading...

Loading...