Do you have a question about the Bosch WT PSI 6 Series and is the answer not in the manual?

Describes graphical symbols used in the manual and on hardware components.

Explains formatting conventions used throughout the document.

Defines the intended application, limitations, and proper usage of the equipment.

Details potential hazards and necessary precautions related to magnetic fields.

Critical safety information regarding potential interference with cardiac pacemakers.

Defines the expertise and training required for safe operation and maintenance.

Provides guidelines for the correct handling, storage, and transportation of the equipment.

Provides crucial steps and safety precautions for correctly setting up the device.

Essential safety and procedural information for wiring the equipment correctly.

Core instructions and safety guidelines on how to use the equipment.

Advises on user-initiated changes and potential safety risks.

Instructions for routine upkeep and troubleshooting of the equipment.

Provides an overview of the welding system components and their purpose.

Explains how the welding system operates at a high-level overview.

Describes the characteristics and operation of the welding current used.

Illustrates the internal structure and interconnections of the timer module.

Details the necessary components and procedures for setting up and running the timer.

Lists the technical specifications and parameters for the welding timer modules.

Outlines the technical specifications and data for the power unit.

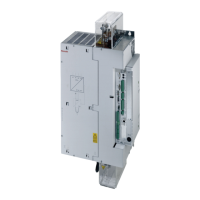

Describes the main functional units comprising the PSI 6XXX.190 W1.

Details the layout and components of the module front panel without specific I/O.

Describes the layout and components of the front panel with type-specific I/O.

Describes various connection interfaces like V24, pressure, and power supply.

Details internal and external power supply configurations and requirements.

Explains how to select and manage seam programs using parallel inputs.

Details timing characteristics for block selection changes and signal responses.

Describes the function of parallel output signals, such as 'Control Ready'.

Guides on setting up basic parameters for seam welding programs.

Details how to program welding parameters in basic and block programs.

Lists the valid input ranges for various welding parameters.

Explains how actual values are calculated for monitoring purposes.

Describes how current monitoring is configured and applied to block programs.

Lists the essential steps to take before starting the commissioning process.

Provides procedures for verifying the functionality of welding programs.

Offers recommendations for performing initial welding tests and parameter checks.

Details the steps for configuring the basic settings and parameters of the timer.

Guidance on checking and adjusting welding parameters during commissioning.

Explains how to adjust welding equipment parameters to real-world conditions.

Provides steps for fine-tuning programmed values for specific welding needs.

Details the steps required to enable and configure current monitoring.

Covers user level definition, parameter protection, and program copying.

Describes the procedures for backing up configured welding parameters.

Explains the types of messages generated by the timer, distinguishing between warnings and faults.

Categorizes messages by type: communication, stepper, timer status, and monitoring.

Lists specific error codes and explanations related to electrode or stepper issues.

Lists error codes and explanations related to the timer's internal status.

Lists error codes and explanations related to current monitoring functions.

Provides step-by-step instructions for replacing the internal backup battery.

Provides a glossary of terms and abbreviations used throughout the manual.

Defines specific terms related to regulation modes and parameters.

An alphabetical listing of topics with corresponding page numbers for easy reference.

| Category | Timer |

|---|---|

| Brand | Bosch |

| Model | WT PSI 6 Series |

| Number of programs | 6 |

| Power supply | 230 V AC |