Exponential line loading is used for all four

drive units, primarily to achieve freedom from

resonance and reflection, but also for the

damping effect on the fundamental resonance

in the low frequencies.

The two dome units are tightly coupled to

their respective wave guides via a hollow pole

magnet which causes minimal discontinuity to

the advancing wave front.

A hollow pole magnet is also to be found

behind the lower mid diaphragm supported by a

chassis which itself forms the first 50mm of the

wave guide. The tube to which this is attached is

shaped to smooth the transition from the chassis.

The distinctive natural appearance of Nautilus

is derived from the best compromise of folding

a tapered tube to save space whilst maintaining

the highest curvature-to-width ratio. Traditionally,

folded pipes have involved many 180° bends

which have serious frequency dependent

transmission properties.

Enclosure

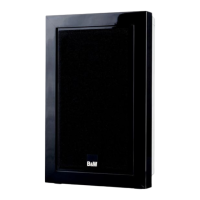

Each drive unit has been developed to

operate as a piston within its intended

frequency band, with two octaves between

the upper roll-off and the first sign of break-

up modes. Extensive use of aluminium in

the diaphragms makes this possible. All

voice coils are wound on polyimide formers

to eliminate eddy-current losses, which are

particularly serious at high frequencies.

A 9.5kg (21lbs) magnet with a 100mm

(4in) voice coil acts as the massive motor of

the 300mm (12in) bass unit. This, when used

in the exponential line enclosure, results in

a high-pass behaviour so over-damped that

the traditional second-order characteristic

is replaced by two distinct first-order slopes

and no stored energy.

A 250 micron one-piece aluminium cone/

centre dome ensures coherent motion to

beyond 1.5kHz. From 220Hz to 880Hz,

a 100mm flat-fronted unit is employed to

prevent the gentle cavity resonance found

in conventional cone units at around 2kHz

interfering with the output from the upper

midrange unit. A rare earth magnet assembly

with hollow pole is used to minimise the

obstruction to the rear radiation from

the diaphragm.

Two domed units of anodised aluminium

of similar construction, 50mm and 25mm

in diameter, handle the 880Hz-3.5kHz and

3.5kHz-25kHz ranges respectively. All drive

units are completely mounted on silicone

rubber O-rings to decouple them from

the cabinet.

Drive units Crossover

The division of the signal into the four required

bandwidths is accomplished in the Nautilus

Active Crossover via totally nonresonant

circuitry. Both inputs and outputs offer

single and balanced operation, the latter

being particularly useful in noisy electrical

environments, although a slight subjective

improvement has been observed when

using balanced signal interconnections at

every stage.

With suitable pre- and power amplifiers,

one unit is required for each loudspeaker

and should be sited close to the power

amplifiers. A power supply connection for

each crossover is required.

10mm thick Glass Reinforced Plastic (GRP) has

been used for the exterior surface which, when

coupled with the doubly curved shape, results

in an extremely stiff enclosure. The inner turns

of the spiral are bounded by a foam filled GRP

which braces the opposite faces of the snail in

a manner similar to the Matrix type enclosure

perfected by B&W.

The external form of the Nautilus has been

achieved using a blend of hand-built forming

and advanced CAD technology borrowed from

the automotive industry. This enables B&W to

maintain mathematical accuracy of the wave

guide and to produce the final mould tool to

submillimetric accuracy.

The high gloss surface finish is the result

of using a two-part acrylic paint with a deep

lacquer coat for lustre and durability. A 50kg

block of polished terrazzo type material supports

the complete mollusc.

Important: your dealer must

check that the serial number

located at the rear of each

crossover unit matches that

of the loudspeaker – and that

the stated voltage is correct

for your mains supply.

Loading...

Loading...