2

7

Take Care

3. Operation

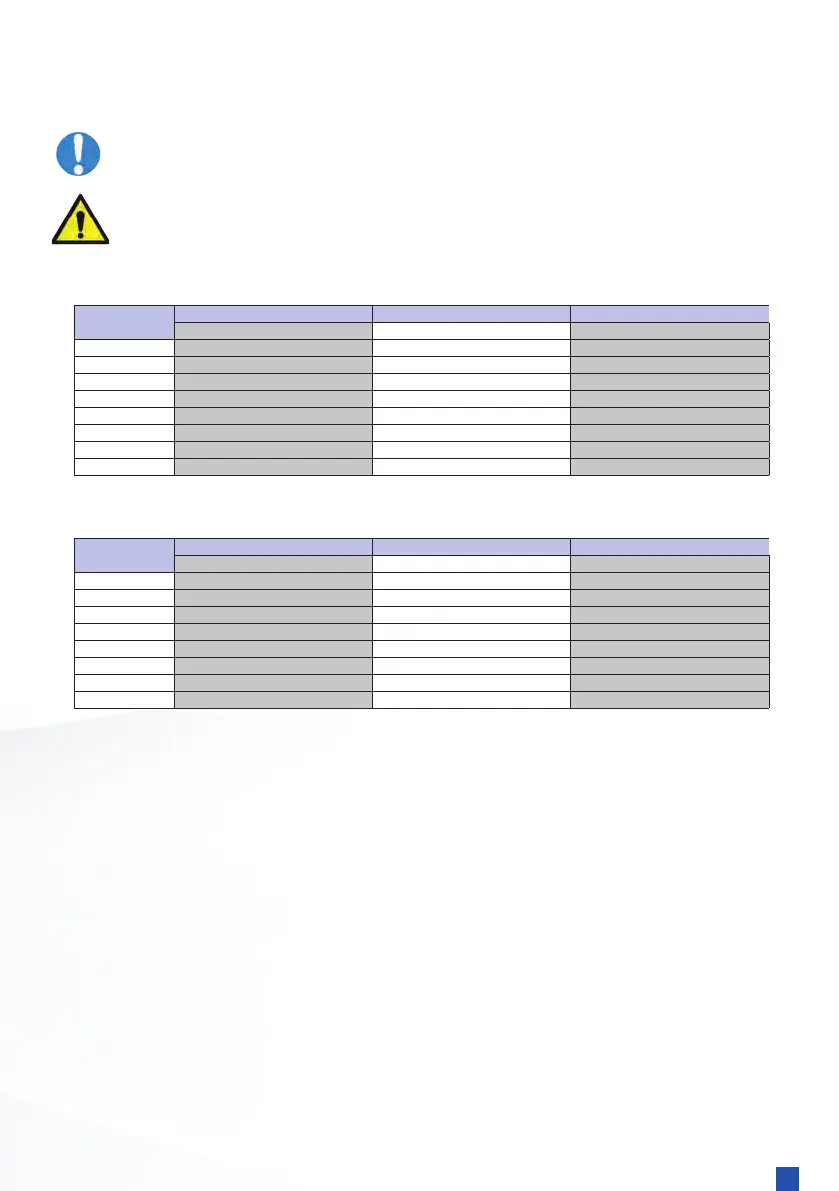

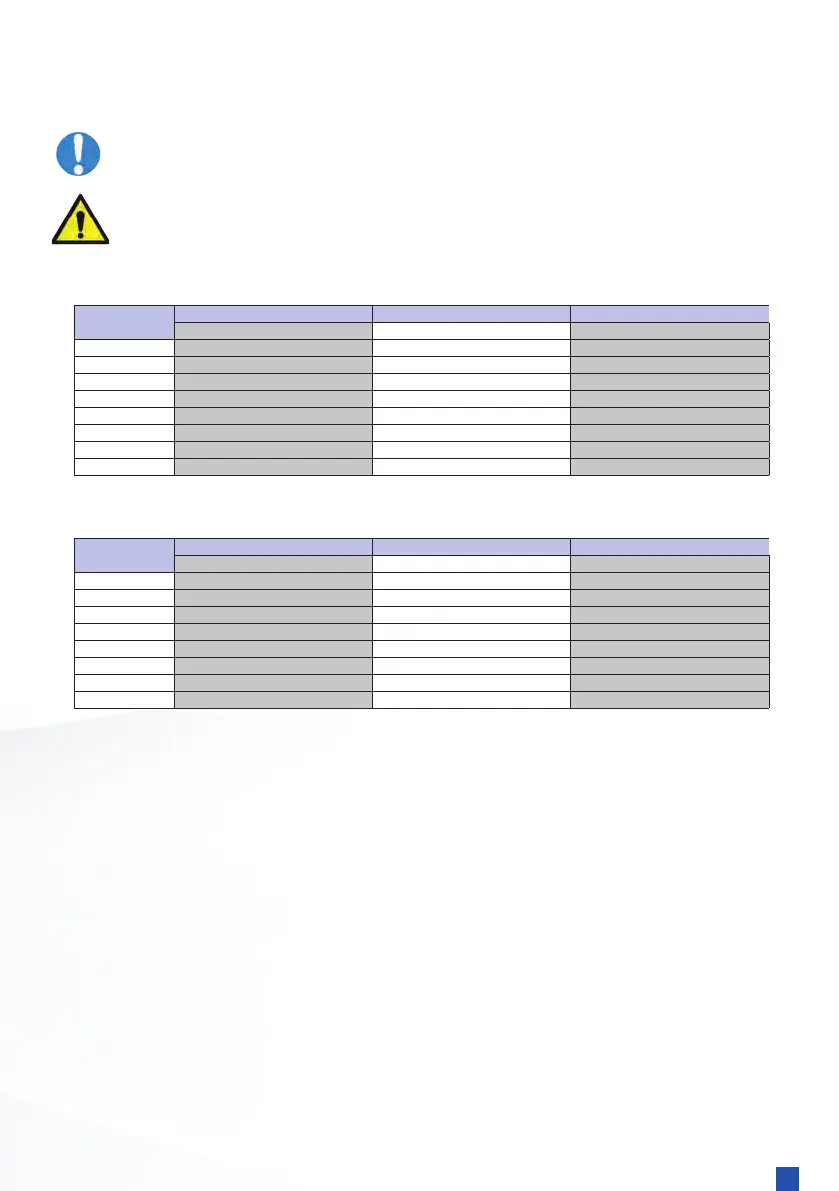

3.1 Maximum water flow rates

The following tables give maximum ow rates through the tube stack for either

single, two or three pass conguration, using either sea or fresh water.

Max Recommended Flowrate (I/min) Max Recommended Flowrate (I/min) Max Recommended Flowrate (I/min)

EC range 50 80 170

FC range 80 120 230

FG range 110 170 320

GL range 200 290 560

GK range 300 450 900

JK range 400 600 1200

PK range 650 1000 2000

RK range 900 1400 2800

Max Recommended Flowrate (I/min) Max Recommended Flowrate (I/min) Max Recommended Flowrate (I/min)

EC range 75 120 255

FC range 135 200 380

FG range 180 270 530

GL range 320 470 900

GK range 460 690 1400

JK range 660 1000 2000

PK range 1000 1500 3000

RK range 1400 2150 4300

Sea Water Application (Maximum 2 m/s)

Fresh water Application (Maximum 3 m/s)

3-Pass

Type

3-Pass

Type

3.2 General information

The oil cooler should be pressurized on the oil (shell) side such that it is at a higher pressure than

the water (tube) side. This will ensure that if a leak occurs it will be detected by a reduction in the

oil level and the oil will not be contaminated. A dierential pressure of 2 bar would be sucient. It

is essential that the following instructions are followed to prevent corrosion/erosion of the heat

exchanger:

a) Always maintain the water pH to within correct levels. The ideal water pH should be kept

within 7.4 to 7.6. On no account should it be below 7.2 or above 7.8.

b) Minimum water velocity of 1m/s should be used.

c) Ensure compliance with water quality and maximum permissible pressure requirements.

d) Air must be adequately vented from both circuits.

e) Stagnant water should not be allowed to accumulate in the oil cooler. If it is not in use

for any period of time the water should be drained o.

2-Pass 1-Pass

2-Pass 1-Pass

Loading...

Loading...