2

9

Take Care

5.2 General maintenance

While the unit is in operation, weekly inspection of the heat exchanger and its connections

should be made for leaks and externally visible damage. BOWMAN® recommend that the

tubestack should be cleaned and inspected annually and the o rings should be renewed at

this time. Removal of the screws around the periphery of each end cover will allow the end

covers and seals to be removed. The tubestack can then be withdrawn from either end of

the body.

5.3 Cleaning

Whilst we strongly recommend that mechanical and chemical cleaning of the heat exchanger is

carried out only by specialised companies, below are some general guidelines that may be useful;

a) Removing the end covers allows access to the tube stack, which can be removed

from the body.

b) Wash the tube plates and tubes using a hand held hose or lance. An industrial steam

cleaner can also be used if available.

c) Tube brushes can be used to clean through each tube to aid removing stubborn deposits.

Small diameter rods and brushes for tube cleaning are available from companies such as

Rico Industrial Services www.ricoservices.co.uk

d) Detergents or chemicals suitable for use with the tube material* can be used if

fouling is severe. Allow time for the detergent or chemical cleaner to work, before hosing

down with plenty of water. *Please refer to the spare parts list for details of the tube materials.

e) The tube stack should be ushed through with clean water to remove all traces

of cleaning chemicals/detergents. If necessary, the cleaning uid should be neutralised.

f ) When retting the end covers after cleaning, new ‘O’ seals must be used

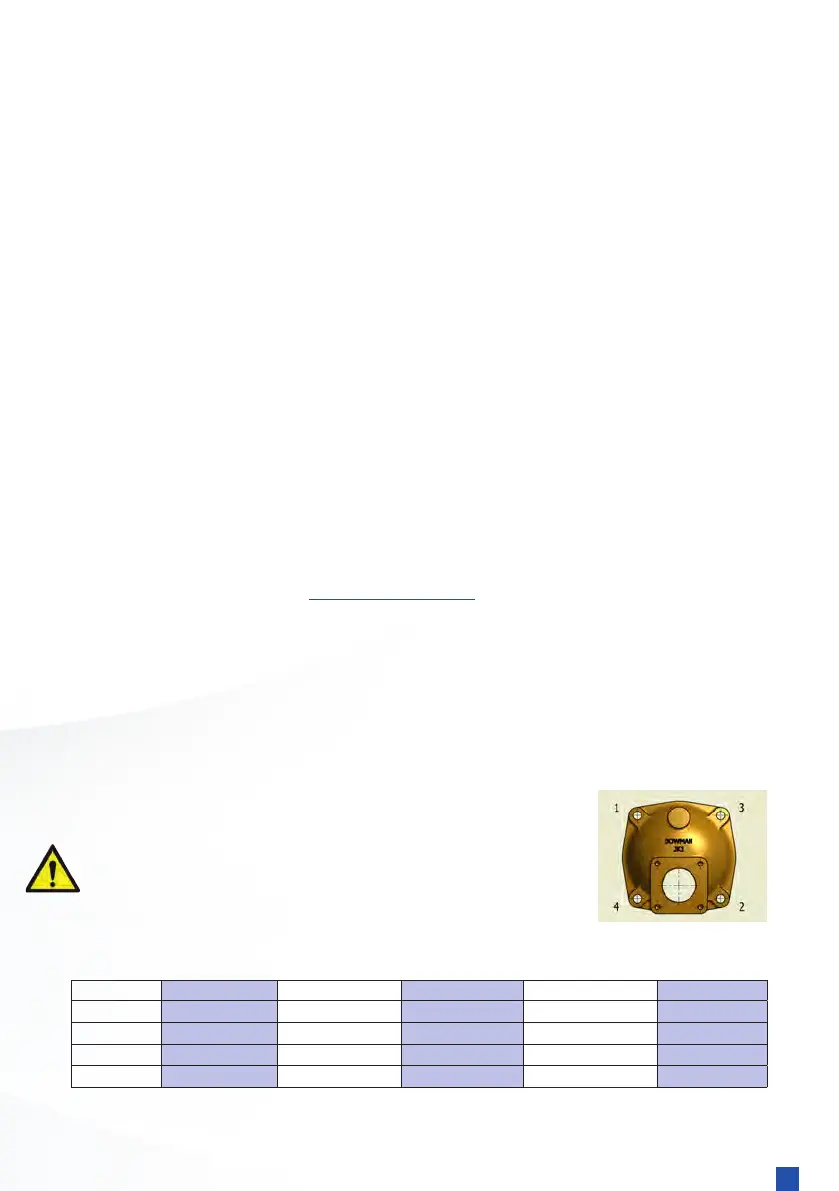

5.4 End cover screw tightening sequence

End covers must be retted in their original

orientation and tightened to the torque gures

below.

Cooler Series Screw Size Torque (Nm) Cooler Series Screw Size Torque (Nm)

EC M6 8 GK M12 54

FC M8 22 JK M16 95

FG M8 22 PK M16 130

GL M10 37 RK M16 130

Loading...

Loading...