Bray Series 6P

Operation and Maintenance Manual

10

5. Piping Connections

NOTICE

To avoid introducing moisture or dust, both supply

andsignalairshouldbeclean,dry,andltered

instrument air.

Supply Pressure Condition

1. Dry air with dew point of at least 50°F (10°C)

lower than ambient temperature.

2. Avoid dirty or oily air. Filtered air is recom-

mended in compliance with ANSI/ ISA-573

1975 (R1981) instrument grade.

3. Do not use beyond the range of

20-100 psig (1.4 - 7.0 barg) supply air.

4. Setairlterregulator’ssupplypressure10%

higher than the actuator’s spring range pressure.

Pipe Condition

1. Make sure the inside of tubing is clean and clear.

2. Do not use tubing that has been pinched or has

holes.

3. Tomaintainproperowrate,useatubesizethat

is at least ¼” (6mm) inner diameter.

4. Do not use extremely long tubing systems.

Itmayaffecttheowrateduetoexcessive

pressure drop.

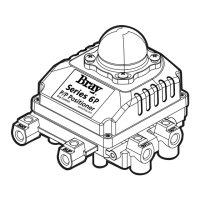

Piping connection with actuator

Series 93 Spring Return Actuator

When mounting on the Bray S93 Spring Return

Actuator, OUT 1 should be connected to port A (left

port when facing the ports) and OUT 2 should be

plugged. This generates increasing pressure, forcing

the pistons away from each other, causing a counter-

clockwise rotation compressing the springs with

increasing signal to the positioner. When mounting

to other manufacturers rack and pinion actuators or

other actuator types, check actuator documentation to

determine proper connection.

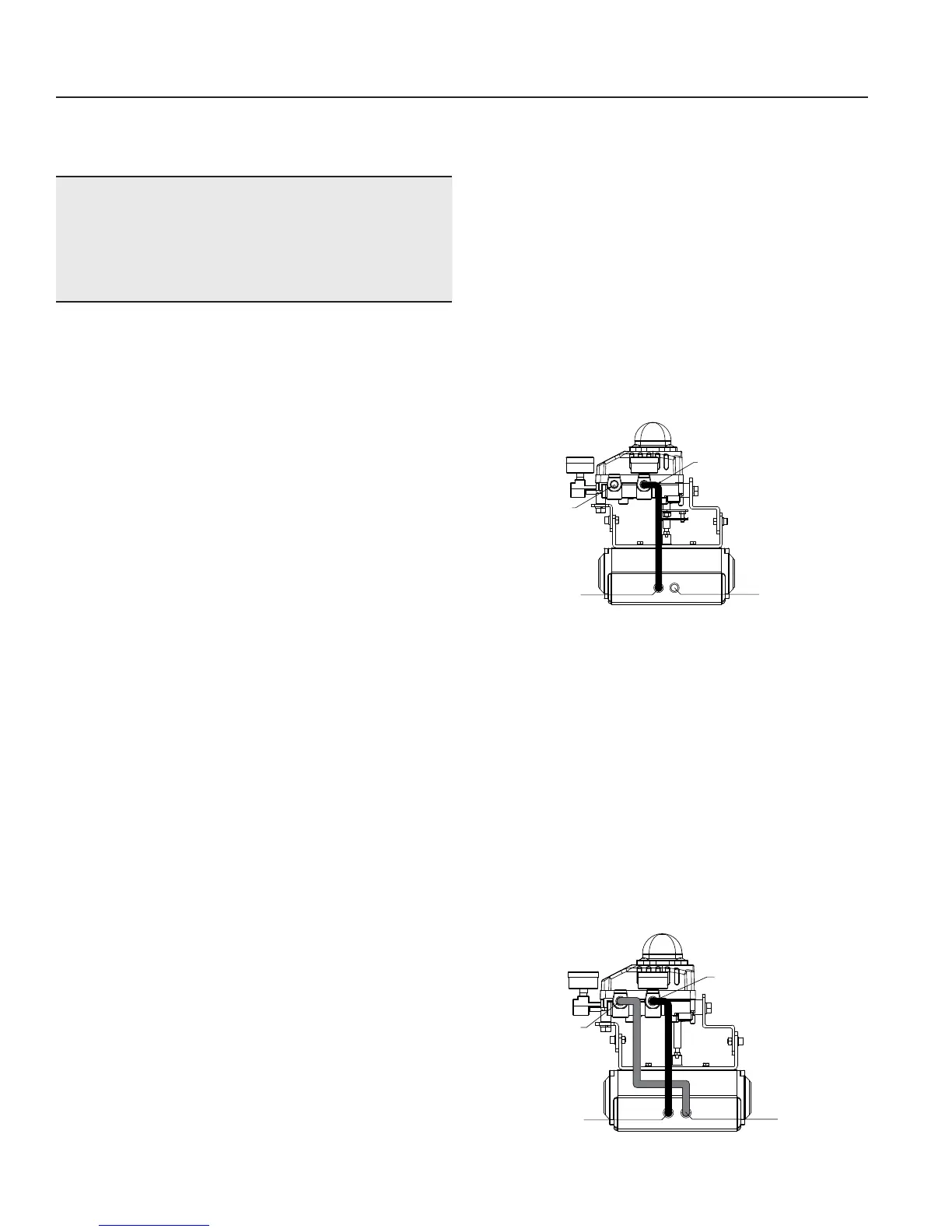

Series 92 Double Acting Actuator

When mounting on the Bray S92 Double Acting

Return Actuator, OUT 1 should be connected to port

A (left port when facing the ports). OUT 2 should be

connected to port B (right port when facing the ports).

These connections will cause the pistons to move

away from each other causing a counter-clockwise

rotation with increasing signal to the positioner, and

clockwise on decreasing signal. When mounting to

other manufacturers rack and pinion actuators or

other actuator types, check actuator documentation to

determine proper connection.

OUT 1

OUT 2

A

B

OUT 1

OUT 2

A

B

Figure 9 - Single Acting

Figure 10 - Double Acting

Loading...

Loading...