7

Maintenance

⚫ It is very important to clean the machine after use. The dry ingredients may stick on the metal and stick inside

the pump.

⚫ Rise the machine with 5L-10L, 70-80℃ water for 15mins or more until you make sure it is clean. Turn on the

pump during cleaning.

⚫ Do not use any sharp metal implement to remove any residue. Use a soft cloth or soft scouring pad to clean the

inside of the boiler. (vinegar can be good for this)

⚫ Any wort residue marks on the boiler base should be cleaned off before next use.

⚫ Reverse flush the pump by connecting a hose to the curved pipe.

⚫ Suitable cleaning products can be used. (please check suitability)

⚫ Do not splash any electronic parts of the machine.

⚫ Do not immerse the machine in water.

⚫ Store the machine in a dry place, do not plug in when not in use.

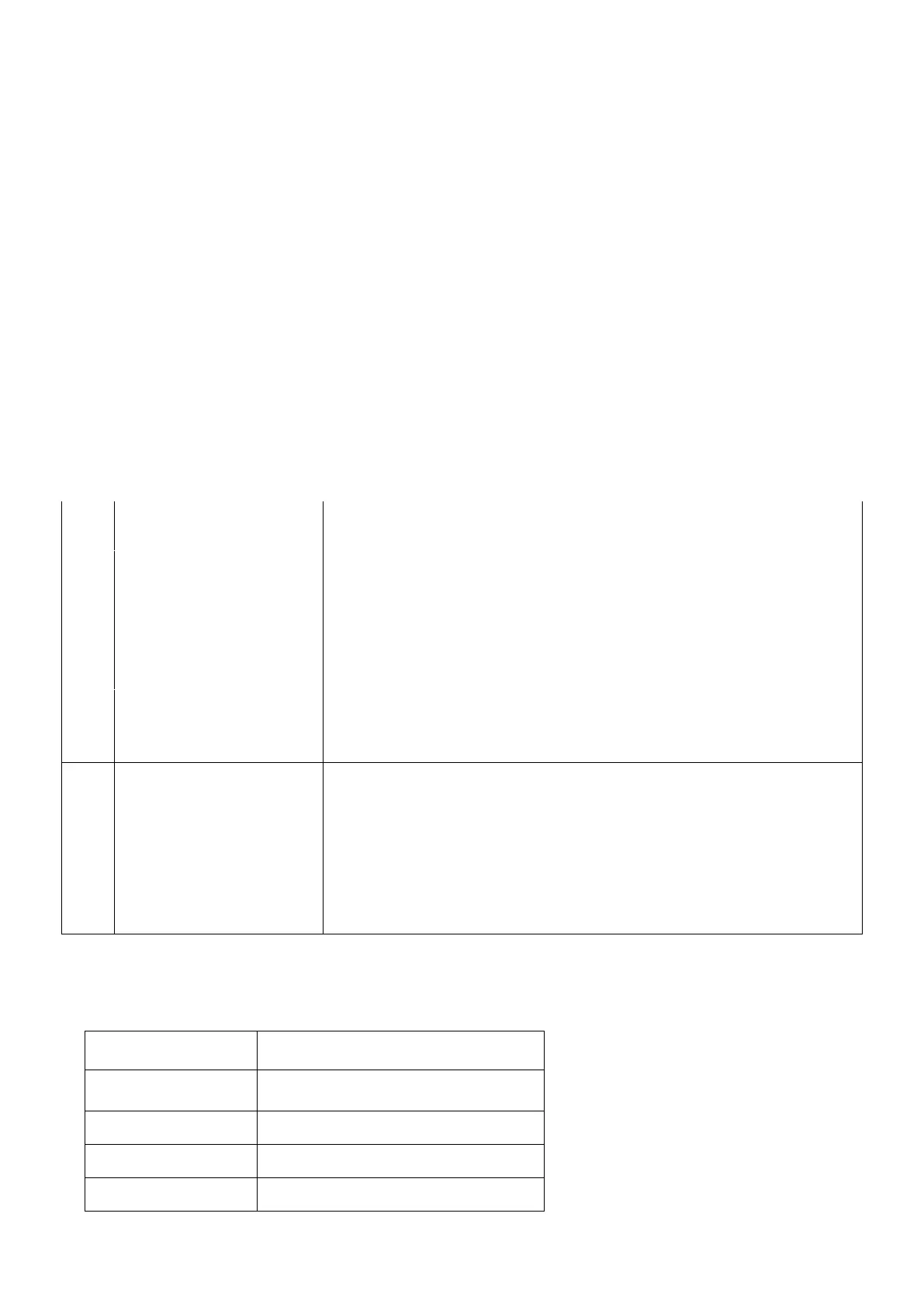

Troubleshooting Tips

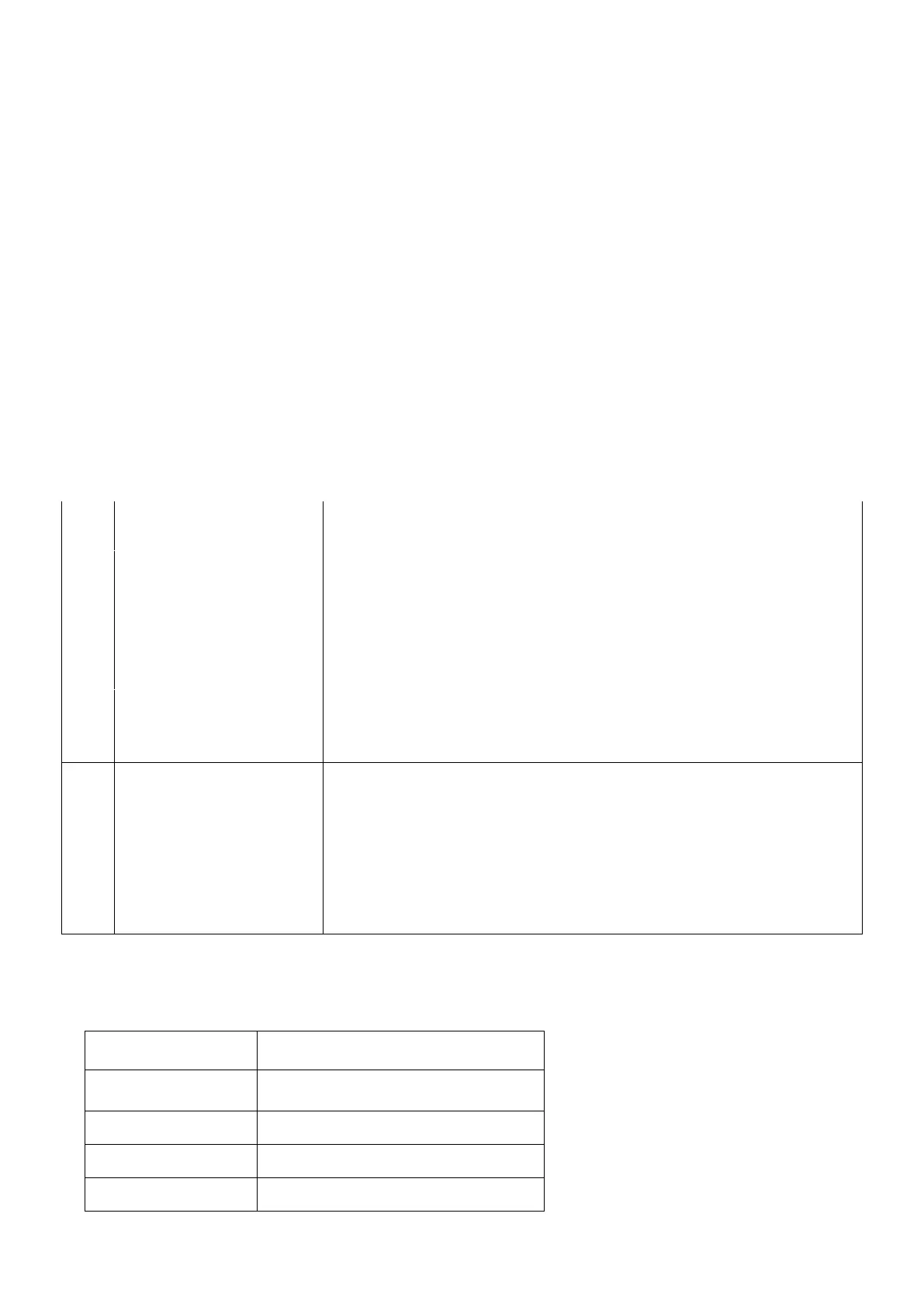

Technical Data

40L up to top, 35L to full line

Ingredients stuck in the

pump

A: Flush the pump by connecting a hose to the curved pipe

B: Dismantle the pump to remove the ingredients.

A: Put the lid on for 1 to 2 mins

B: Make a temperature correction.

C1--degree centigrade

temperature correction

A: Press "-" and "+" at the same time to enter C1 temperature correction

setting. Setting range is from -10℃ to +10℃, press TEMP button to

confirm.

F1--Fahrenheit

temperature correction

A: Press "-" and "+" at the same time to enter C1 temperature correction

setting. Setting range is from -50℉ to +50℉, press TEMP button to

confirm

A: Temperature is lower than -20℃, it is low temperature warning.

B: Senor connector is loose.

C: Open the underneath and check the sensor. Re-connect it if loose.

A: Temperature is higher than 120℃, it is overheat/boil-dry warning.

B: Sensor is out of order, please contact dealer for replacement.

Suddenly shut off during

heating

A: Lower the heat up power

B: Replace overheat protection fuse

Loading...

Loading...