31

2

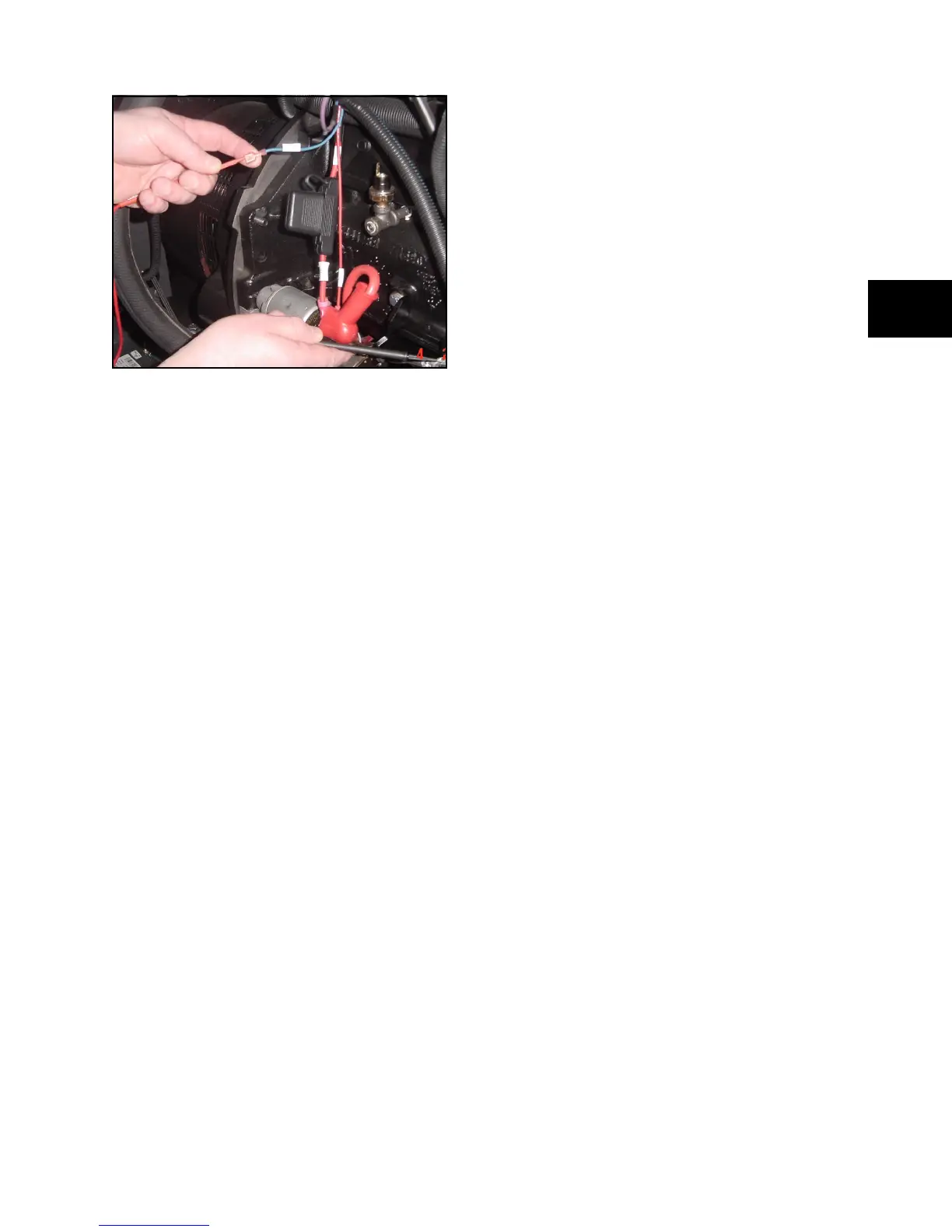

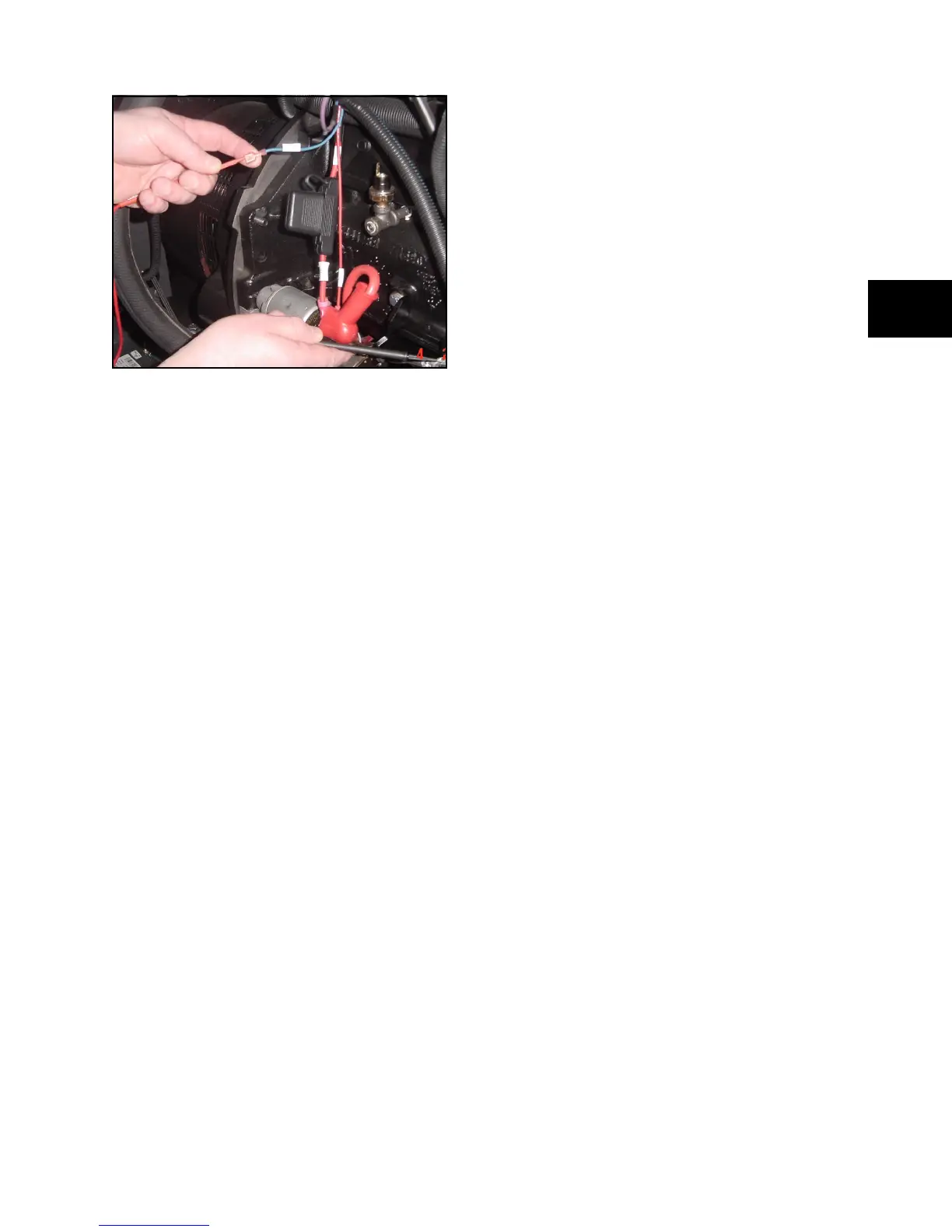

Figure 21

• If no short is detected, proceed to

TEST 2 - Check Engine Oil Pressure.

• If short is detected, continue with Steps

7 - 12.

7. Repair and/or replace wiring, as

necessary, then retest.

8. Reconnect Wire #85 to the LOP switch.

9. Reconnect the 8-pin connector to the

system control panel.

10. Reinstall the control panel cover.

11. Reinstall the 15 Amp fuse in the system

control panel.

12. Set the SYSTEM to AUTO, then push

and hold MANUAL OVER-RIDE to start

the unit.

TEST 2 - Check Engine Oil Pressure

Contact Power Solutions, Inc (PSI Technical

Service Specialists: 1-888-331-5764 or at:

Servce@PowerGreatLakes.com) for

specifications, testing, and troubleshooting

engine oil pressure.

• If oil pressure is normal, proceed to

TEST 3 - Check Oil Pressure Switch.

• If oil pressure is low, contact engine

manufacturer for engine

troubleshooting procedure.

TEST 3 - Check Oil Pressure Switch

1. If it is not already, install the LOP switch.

2. Turn the SYSTEM switch to AUTO. Push

and hold the MANUAL OVER-RIDE

switch to start the engine.

3. With the engine running, check the switch

with a continuity tester The switch

contacts should be open (no continuity).

• If the switch is OK, replace the system

control panel, and proceed to Step 4.

• If the switch is defective, replace it and

continue with Steps 4-9.

4. Reset the fault code detection system.

SEE RESETTING THE FAULT CODE SYSTEM ON

PAGE 19.

5. Start the generator and verify FC_2 does

not occur.

6. Set SYSTEM switch to OFF.

7. Turn UTILITY ON (if turned off).

8. Return SYSTEM switch to AUTO.

9. Reset the Exercise Timer.

SEE SETTING THE EXERCISE TIMER ON

PAGE 13.

Loading...

Loading...