BRIGGS & STRATTON CORPORATION

Milwaukee, WI 53201

Part No. 275429-1/04 Printed in U.S.A.

www.briggsandstratton.com

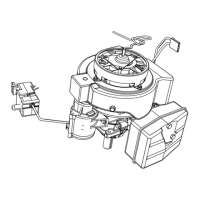

272147 - Single Cylinder OHV Air-Cooled Engines

272144 - Vanguard™ Twin Cylinder OHV Air-Cooled Engines

275429 - Vanguard™ Twin Cylinder OHV Liquid-Cooled Engines

MS-0750 - Vanguard™ 3-Cylinder OHV Liquid-Cooled Gasoline Engines

MS-1055 - Vanguard™ 3-Cylinder OHV Liquid-Cooled Diesel Engines

Quality Starts With A

Master Service Technician

Other Briggs & Stratton

Commercial Power Repair Manuals:

Vanguard Twin Cylinder

OHV Liquid-Cooled Engines

Briggs & Stratton

VANGUARD™ TWIN CYLINDER OHV LIQUID-COOLED ENGINES

Part No. 275429-1/04

REPAIR MANUAL

™

275429_2LC_.1875_Spine 3/29/06 11:11 AM Page 1

For Briggs & Stratton Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com