BRONKHORST

®

9.17.022 page 31

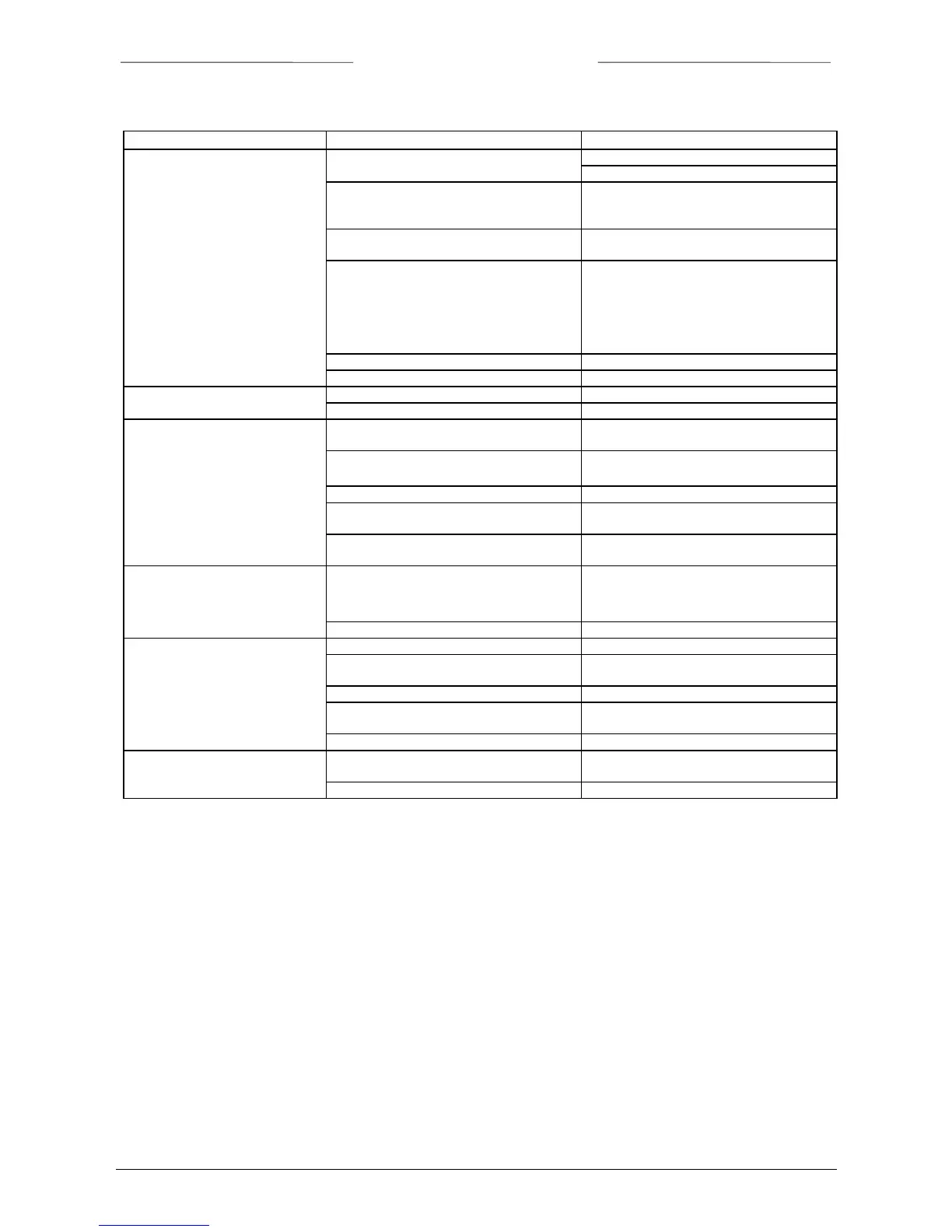

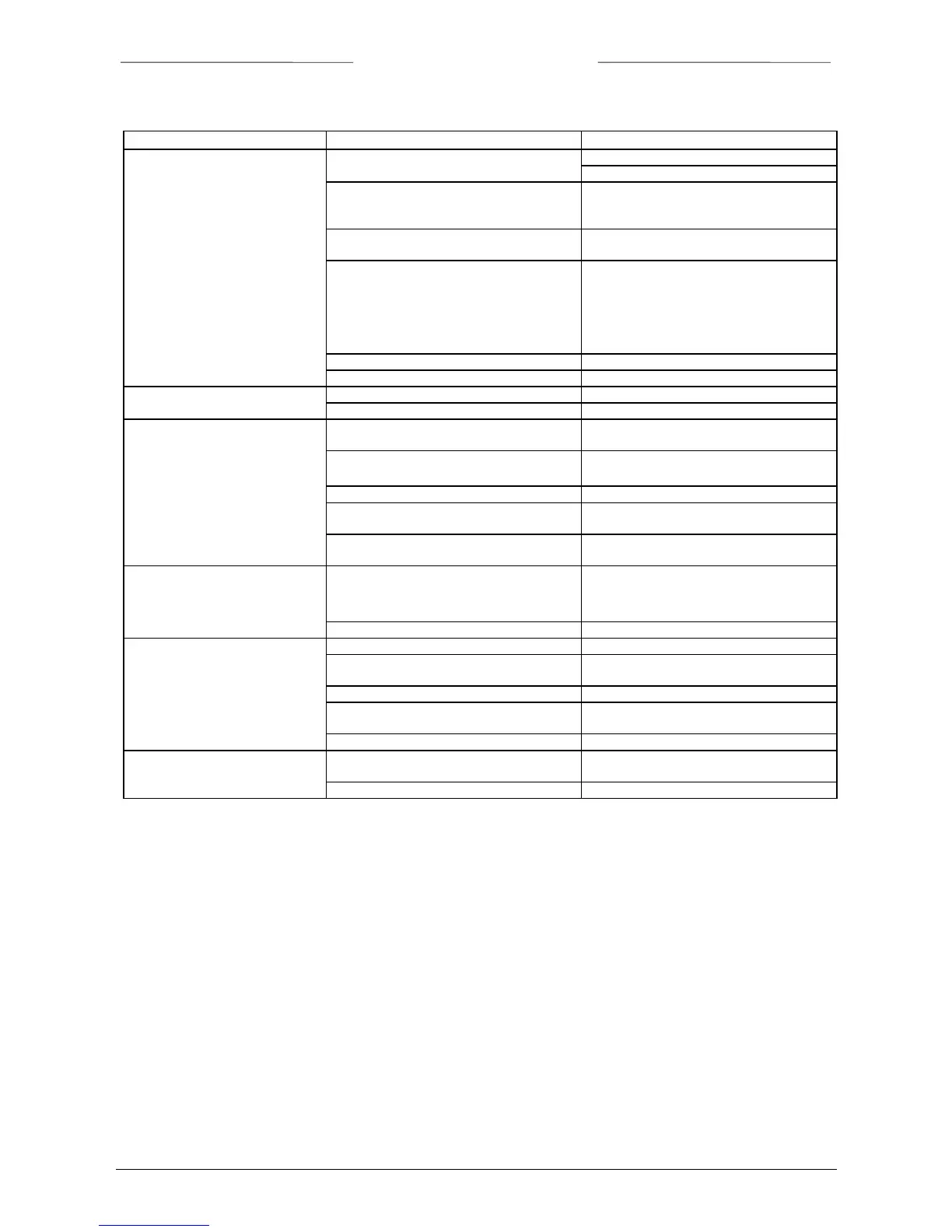

7.2 Troubleshooting summary general

Symptom Possible cause Action

No output signal No power supply 1a) check power supply

1b) check cable connection

Output stage blown-up due to long

lasting shortage and/or high-voltage

peaks

1c) return to factory

Supply pressure too high, or differential

pressure across meter too high

1d) lower supply pressure

Valve blocked/contaminated 1e) connect 0 .. 15 Vdc to valve and

slowly increase voltage while supply

pressure is ‘on’. The valve should open

at 7V

3V; if not open, then cleaning

parts and adjust valve (qualified

personnel only)

Screen in inlet fitting blocked 1f) clean screen

Sensor/capillary failure 1g) return to factory

Maximum output signal Output stage blown-up 2a) return to factory

Sensor/capillary failure 2b) return to factory

Output signal much lower than

setpoint signal or desired flow

Screen blocked/contamined 3a) clean screen

LFD blocked/contaminated and/or liquid

in meter

3b) remove LFD and clean; dry meter

with air or

N

2

Valve blocked/contaminated 3c) clean valve

Valve internals damage (swollen seat in

plunger)

3d) replace plunger assembly and adjust

valve or return

Incorrect type of gas is used and/or

pressure/diff. pressure

3e) try instrument on conditions for which

it was designed

Flow is gradually decreasing

Condensation, occurs with

NH

3

,

hydrocarbons such as

CH,CH

38 410

etc.

4a) decrease supply pressure and/or

heat gas to be measured

Valve adjustment has changed 4b) see ‘1e’

Oscillation Supply pressure/diff. pressure too high 5a) lower pressure

Pipeline too short between pressure

regulator and MFC

5b) increase length or diameter of piping

upstream

Pressure regulator is oscillating 5c) replace pressure regulator or try ‘5b’

Valve sleeve or internals damaged 5d) replace damaged parts and adjust

valve, see ‘1e’ or return to factory

Controller adjustment wrong 5e) adjust controller

Small flow at zero setpoint Valve leaks due to damaged plunger or

dirt in orifice

6a) clean orifice and/or, when replacing

plunger assembly, see ‘1e’

Pressure too high or much too low 6b) apply correct pressure

Note: For other (more specific) problems see also troubleshooting parts in other documents.

Loading...

Loading...