~.

i

l

l

r

I

I

r

!

i

!

~

I

I

.

I

l

J

I

I

~

IT]

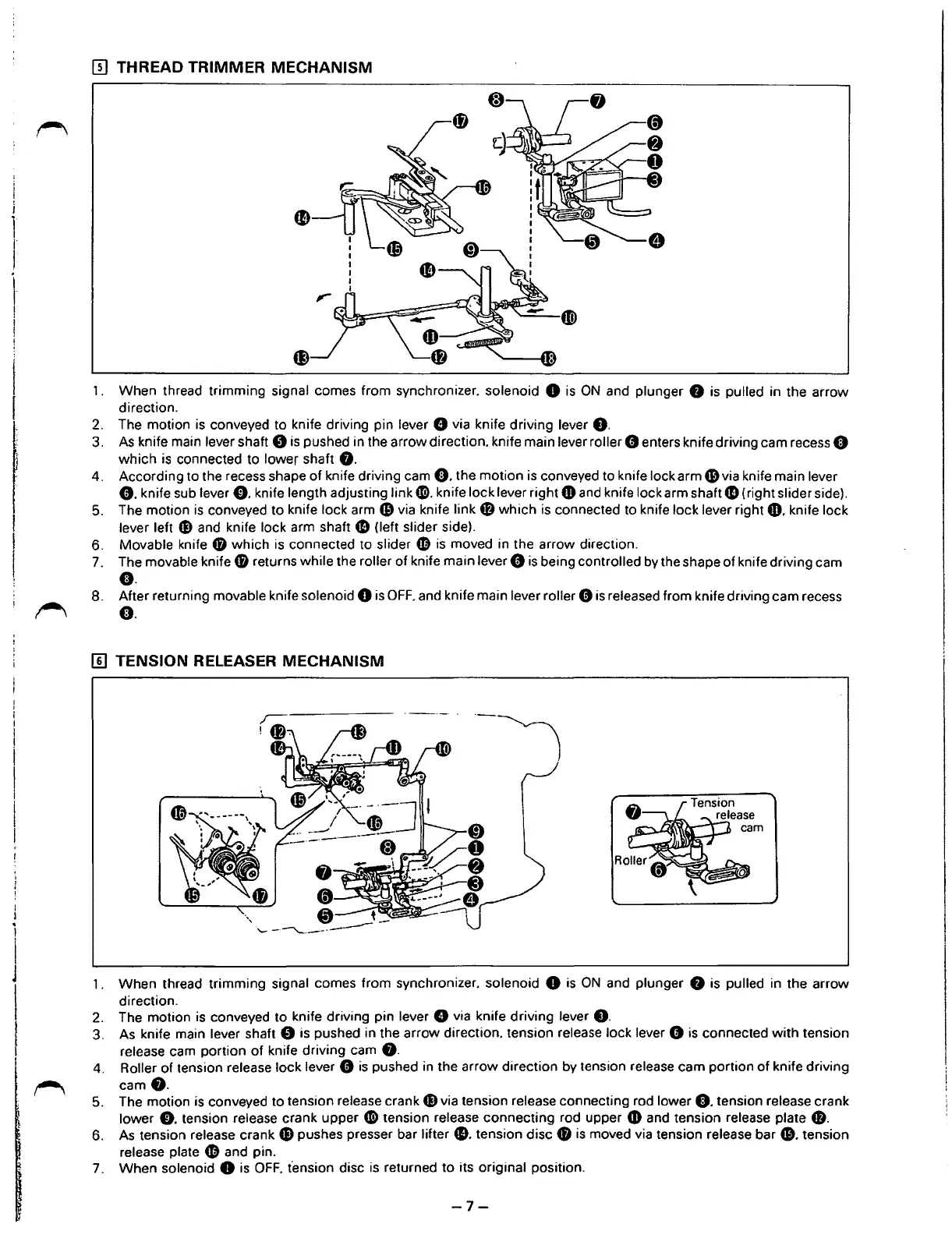

THREAD TRIMMER MECHANISM

1.

2.

3.

4.

5.

6.

7.

8.

When thread trimming signal comes from synchronizer. solenoid 8

is

ON

and plunger 8

is

pulled in the arrow

direction.

The motion

is

conveyed to knife driving pin lever 8 via knife driving lever

8.

As

knife main lever shaft 8

is

pushed in the arrow direction. knife main lever roller 8 enters knife driving cam recess e

which

is

connected to lower shaft

8.

According to the recess shape of knife driving cam

e.

the motion

is

conveyed to knife lock arm

6)

via knife main lever

8.

knife sub lever

0.

knife length adjusting link

CD.

knife lock lever right

4D

and knife lock arm shaft

G)

(right slider side).

The motion

is

conveyed to knife lock arm

6)

via knife link

4B

which

is

connected to knife lock lever right

49.

knife lock

lever left

G)

and knife lock arm shaft

G)

(left slider side).

Movable knife

0 which

is

connected to slider

fD

is

moved in the arrow direction.

The movable knife

0 returns while the roller of knife main lever 8

is

being controlled

by

the shape of knife driving cam

e.

After returning movable knife solenoid 8

is

OFF.

and knife main lever roller G

is

released from knife driving cam recess

e.

[[]

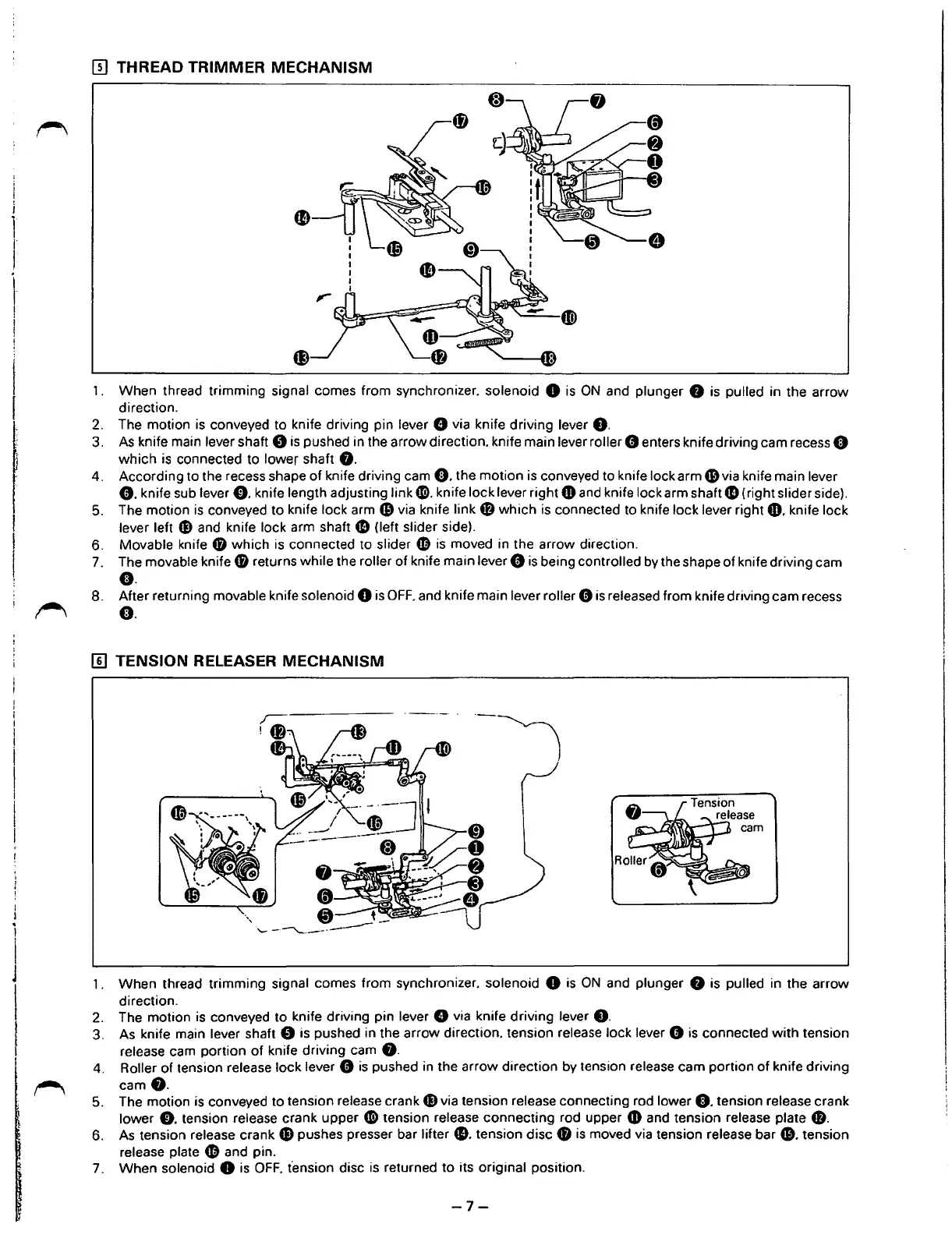

TENSION RELEASER MECHANISM

1 .

2.

3.

4.

5.

6.

7.

When thread trimming signal comes from synchronizer. solenoid 8

is

ON

and plunger 8 is pulled in the arrow

direction.

The motion

is

conveyed to knife driving pin lever 8 via knife driving lever

0.

As knife main lever shaft 8 is pushed in the arrow direction. tension release lock lever 0

is

connected

with

tension

release cam portion of knife driving cam

8.

Roller of tension release lock lever 8

is

pushed in the arrow direction by tension release cam portion

of

knife driving

cam8.

The motion is conveyed to tension release crank

G)

via tension release connecting rod lower

e.

tension release crank

lower

0.

tension release crank upper

CD

tension release connecting rod upper

4D

and tension release plate

8.

As

tension release crank

G)

pushes presser bar lifter

41).

tension disc 0 is moved via tension release bar

41.

tension

release plate

fD

and pin.

When solenoid

8

is

OFF.

t'ension disc

is

returned to its original position.

-7-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...