l

I

I

J

J

I

I

[[]

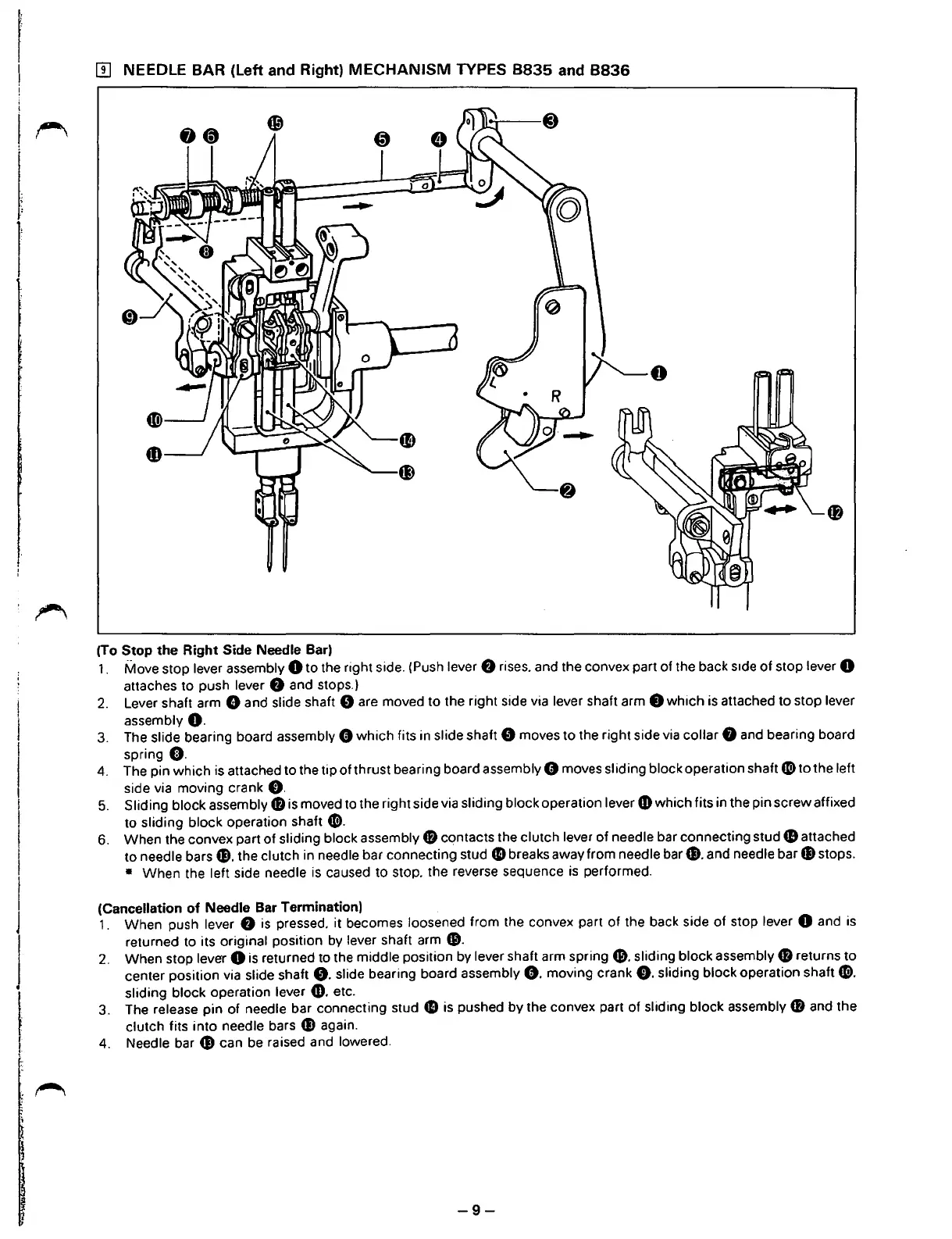

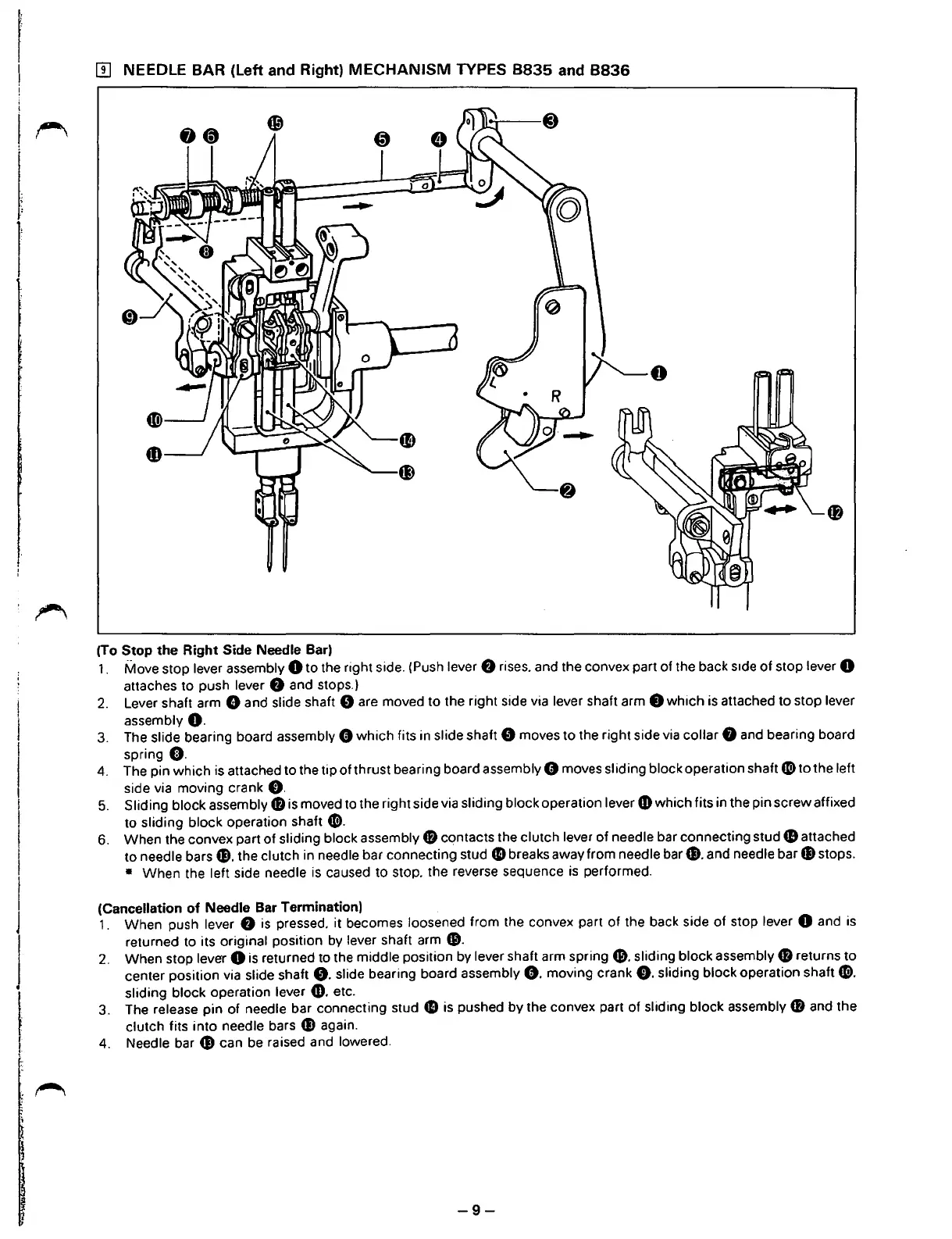

NEEDLE BAR

(left

and Right)

MECHANISM

TYPES

8835

and

8836

(To Stop the Right Side Needle Bar)

1.

Move stop lever assembly 0 to the right side. (Push lever

f)

rises. and the convex part of the back

s1de

of stop lever 0

attaches to push lever

f)

and stops.)

2.

Lever shaft arm 8 and slide shaft 0 are moved to the right side via lever shaft arm 8 which is attached to stop lever

assembly

O.

3.

The slide bearing board assembly 8 which fits in slide shaft 0 moves to the right side via collar 8 and bearing board

spring

0.

4. The pin which is attached to the tip of thrust bearing board assembly 8 moves sliding block operation shaft

G)

to the left

side via moving crank

0.

5.

Sliding block assembly

48

is moved to the right side via sliding block operation lever

CD

which fits in the pin screw affixed

to sliding block operation shaft

G).

6.

When the convex part

of

sliding block assembly

fB

contacts the clutch lever of needle bar connecting stud

41

attached

to needle bars

fl). the clutch in needle bar connecting stud

41

breaks away from needle

bar~.

and needle bar fl) stops.

• When the left side needle

is

caused to stop. the reverse sequence

is

performed.

(Cancellation

of

Needle Bar Termination)

1. When push lever

f)

is

pressed. it becomes loosened from the convex part

of

the back side

of

stop lever 0 and is

returned to its original position

by

lever shaft arm

CD.

2.

When stop lever 0 is returned to the middle position by lever shaft arm

spring&.

sliding block assembly

fB

returns

to

center position via slide shaft

0.

slide bearing board assembly

0.

moving crank

0.

sliding block operation shaft

G>.

sliding block operation lever

CD.

etc.

3. The

release pin of needle bar connecting stud

41

is

pushed by the convex part of sliding block assembly

CD

and the

clutch fits into needle bars fl) again.

4. Needle bar G) can

be

raised and lowered.

-9-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...