32

BROWN 800 Series Brush Cutter

BLADE BAR INSTALLATION

NOTE: Prior to blade bar installation, ensure that the output shaft and the hub are clean and dry.

Apply anti-seize compound to the hub or shaft.

Step 1 - Remove or secure hydraulic lines so the cutter can be turned upside down.

Step 2 - Using a suitable lift, turn the cutter upside down, being careful not to damage the bearing

housing. The cutter should rest on the front and rear headers, use blocking if necessary.

Step 3 - Be sure that the output shaft is clean, coat splines with copper anti-seize. Be sure the splines

of the hub in the blade bar are clean and dry.

Step 4 - Carefully take the blade bar and position it over the tapered splined output shaft making sure

the splines are aligned. The bar should go down approximately 2 3/4” on the shaft. The hub

should remain ABOVE the end of the shaft approximately 0.25 inches.

Step 5 - Install the nut on the output shaft and tighten to approximately 300 ft lb with a 2” 6 point

socket.

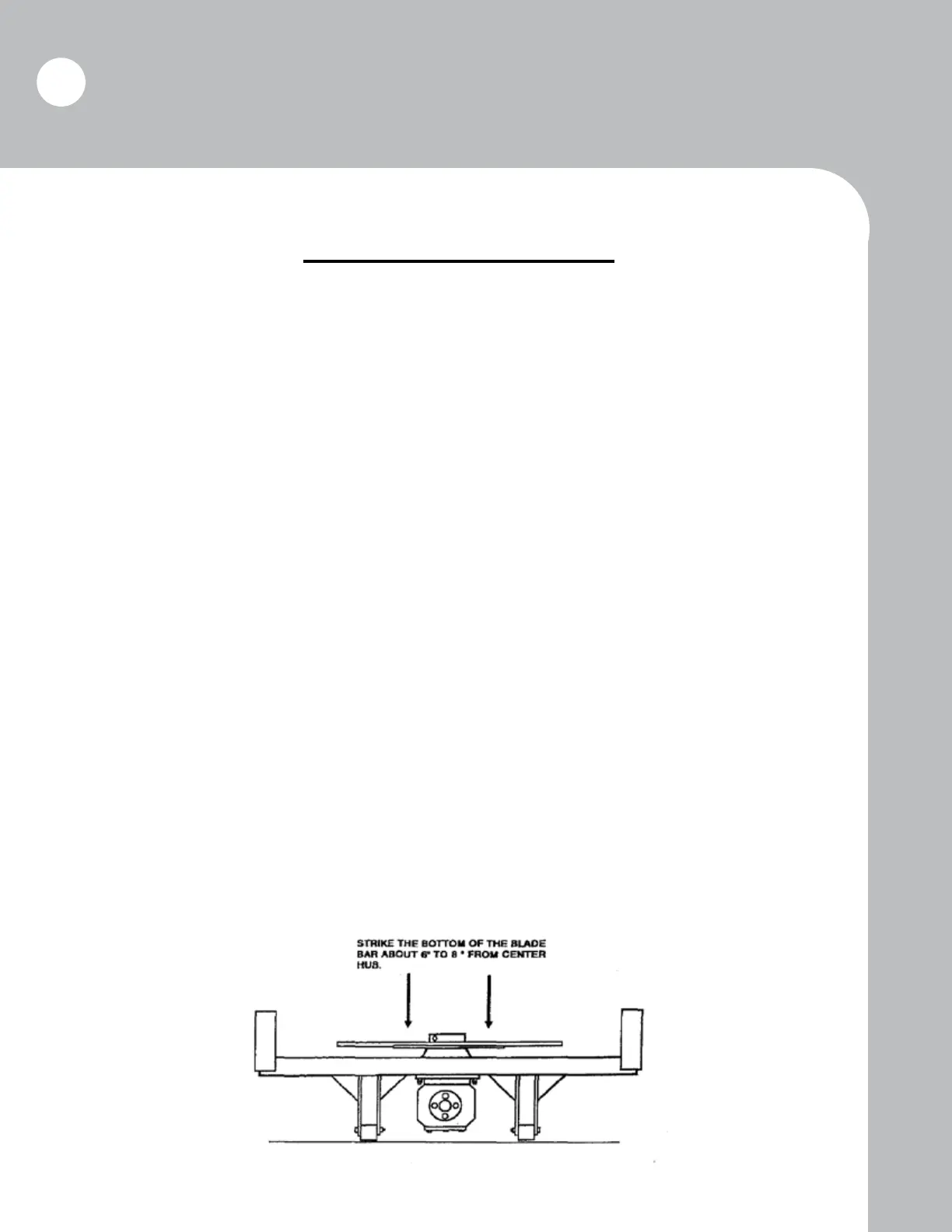

Step 6 - Take an 8 to 12 lb. sledge hammer and hit the bottom of the blade bar several times,

approximately 6 inches from the hub, in a circular pattern around the hub.

Step 7 - Tighten the bar again to approximately 300 ft lb.

Step 8 - Repeat Step 6, hitting the bar with hammer.

Step 9 Retighten the nut to approximately 600 ft lb torque. Remove the wrench from the nut and

check the location of the cotter pin slot and the hole in the shaft. If the hole and slot are not

aligned, continue tightening the nut until the hole and slot are aligned and insert the

cotter pin. If after tightening the nut to a maximum if 600 ft lb of torque the hole and slot

are still not aligned, install a different nut and repeat the tightening procedure. NEVER

loosen the nut to align for cotter pin installation.

Blade Bar Installation Procedure

Loading...

Loading...