Replacement Parts

Motor/Bearing Housing(continued)

41

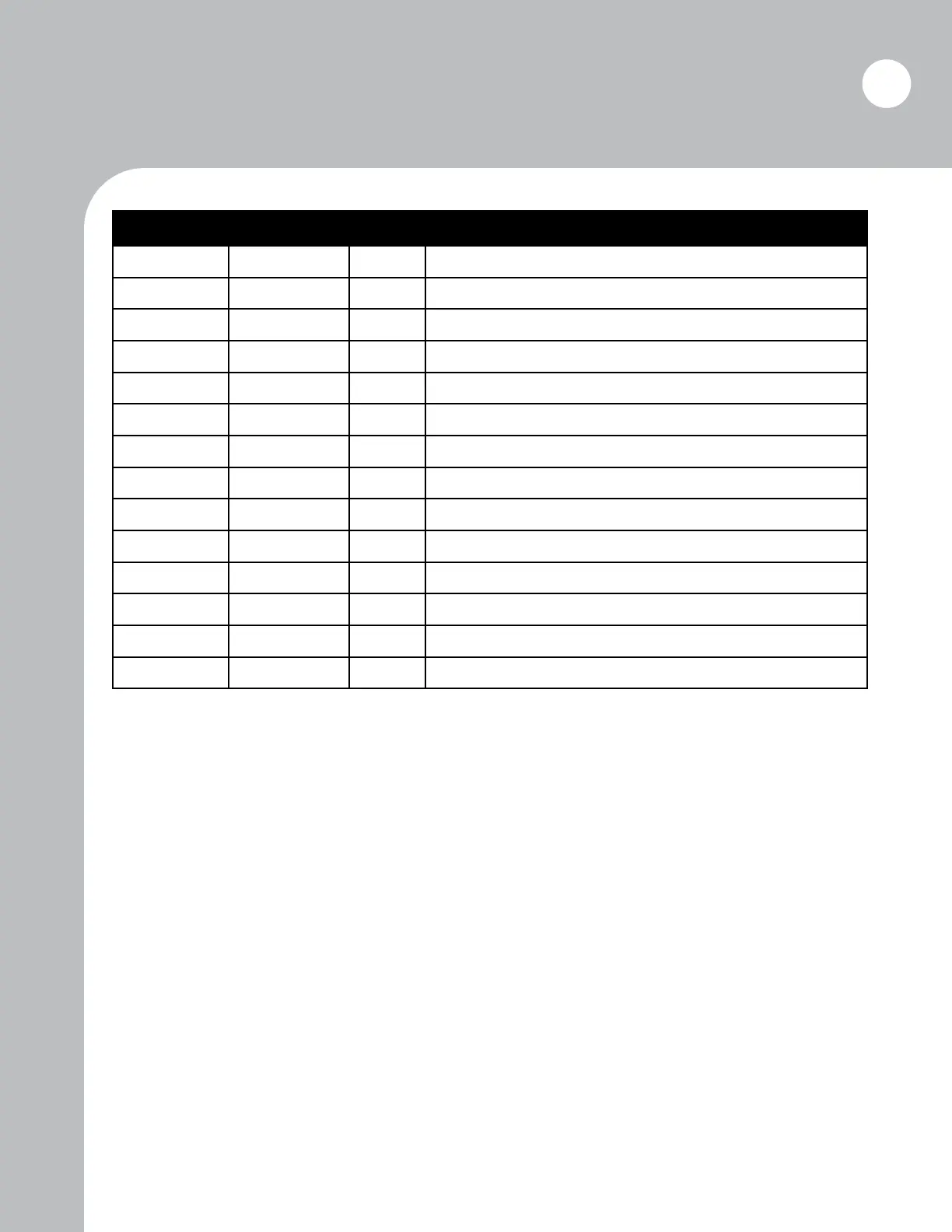

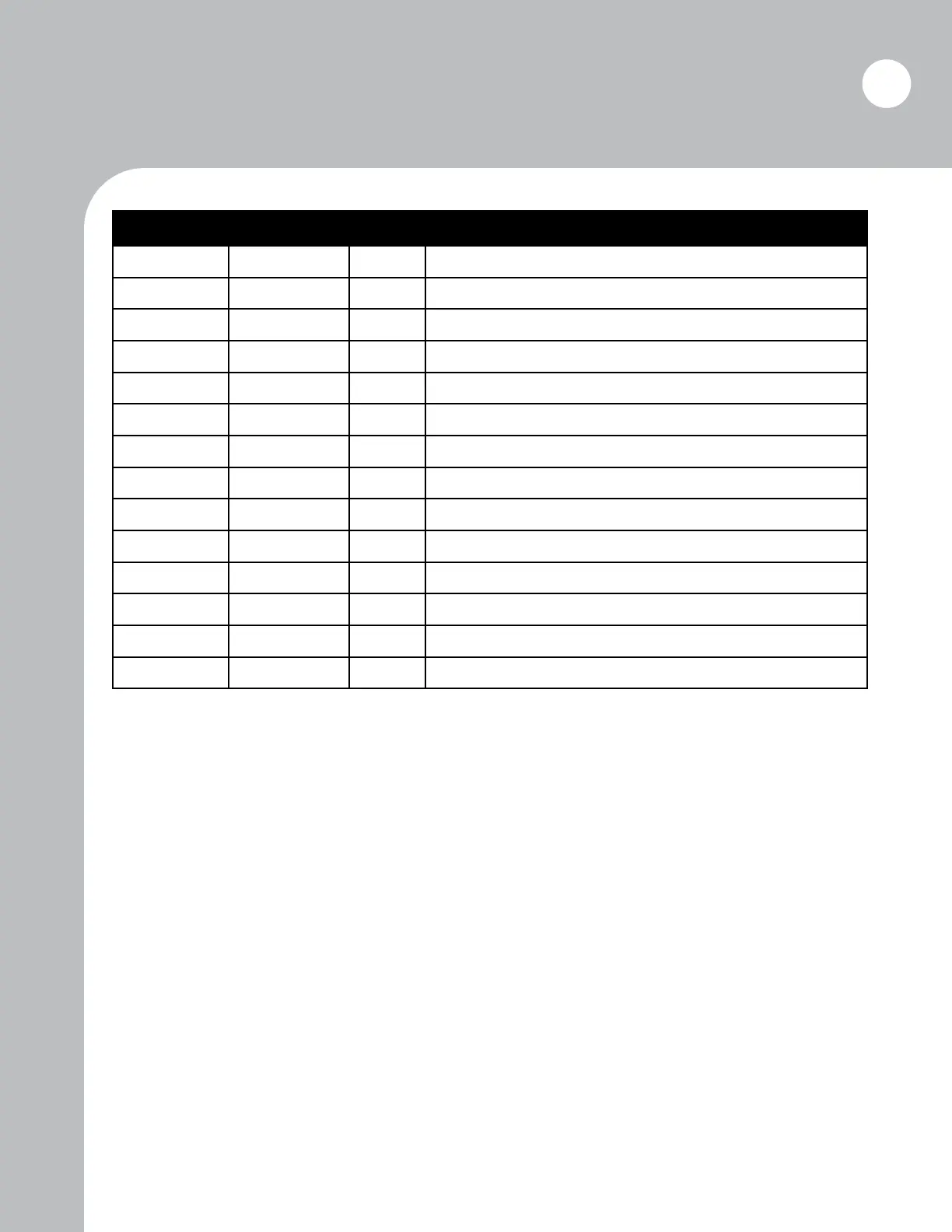

Ref. No. Part No. Qty Description

30 233-82027 1 Hydraulic Motor

31 235-6000 1 Bearing Housing (Complete, without Hub)

32 235-8014 1 Shaft

33 235-32012X 2 Bearing, Cup and Cone

34 235-6305 1 Washer w/ Tang

35 235-6124 1 Lock washer, M60

36 235-6012 1 Bearing Lock Nut, M60-2

37 235-6005 1 Set Screw M5

38 235-60319 1 Lower Seal

39 235-6801 1 Seal Protector

40 235-8018 1 Blade Bar Hub ( welded in 232-0860)

41 235-6114 1 Slotted Hex Nut, 1 1/4”, Washer Bottom

42 235-3015 1 Cotter Pin, 6.3mm x 60mm Zinc, Hammerlock

43 T5-068B 2 3/8” Pipe Plug NPT

START UP - Installation of new motor:

Before connecting any tubes ensure that they are clean, any excess material that could work loose

should be removed. There should not be any oxidation of surfaces that come into contact with the

oil. Make sure the motor casing is lled with oil. Before starting work, the hydraulic circuit

should be purged of air. This can be achieved by running the motor without load for 10-20 minutes,

during which time checks should be made for oil leaks. During the rst few hours of working under

load checks should be made for leakages from connections and ensure that all components remain

rmly xed to their supports.

The motors are factory tested and do not require a wear in period.

START UP - Installation of new or rebuilt bearing housing:

Place bearing housing on level surface, ll housing with approximately 1 pint of T5-LUBE, 85-140

Weight Oil. Settling will occur, especially in cold weather. Put a small bead of RTV sealant around

the inside perimeter of the top bearing housing mating ange, place the motor on top of the bearing

housing and install and torque bolts to 52 ft/lbs. Bolts are listed as item 9 on Page 39. Install this unit

with motor hydraulic ports facing the rear of the machine.

Loading...

Loading...