3

A

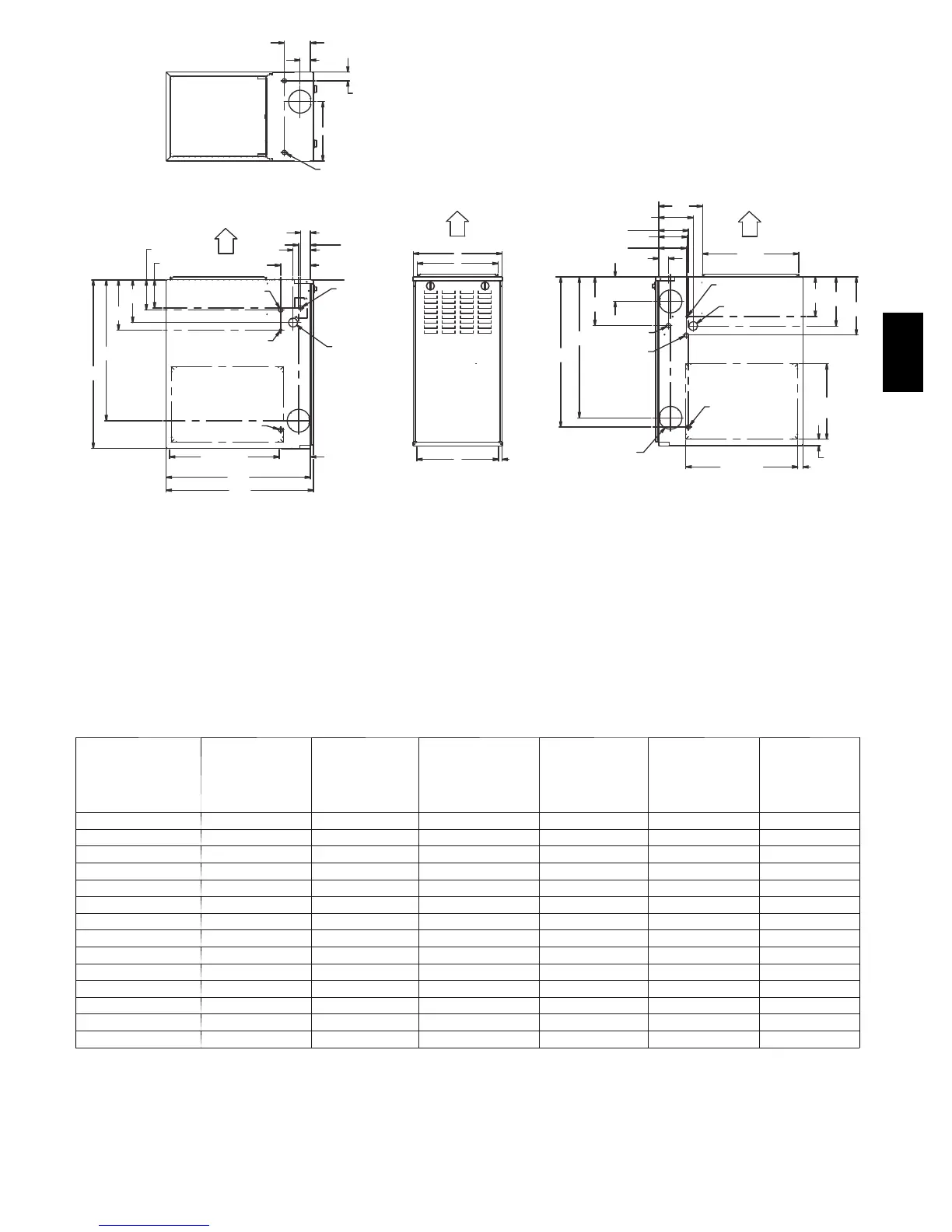

[736.9]

29

Ø7/8

[22.2]

ACCESSORY

5 15/16

[150.7]

28.39

[721.2]

Ø7/8

[22.2]

ACCESSORY

14 7/8

[337.3]

(BOTH SIDES)

Ø7/8

[22.2]

ACCESSORY

Ø7/8

[22.2]

ACCESSORY

Ø1 3/4

[44.5]

GAS ENTRY

Ø1/2

[12.7]

THERMOSTAT WIRE ENTRY

22 1/16

[560]

SIDE INLET

(BOTH SIDES)

11 7/16

[290.7]

9 11/16

[245.4]

[197.8]

7 13/16

Ø7/8

[22.2]

J.BOX PROVISION

Ø7/8

[22.2]

JUNCTION BOX

LOCATION

Ø1 3/4

[44.5]

GAS ENTRY

1 15/16

[49.2]

[25.4]

1 1/4

[31.8]

29 9/16

[750.7]

1 15/16

[49.2]

5 5/8

[143.3]

5 7/16

[138.5]

6 13/16

[172.3]

Ø1/2

[12.7]

THERMOSTAT WIRE ENTRY

19

[481.7]

OUTLET

21.6

[549.5]

BOTTOM INLET

33 1/4

[843.9]

9 9/16

[243.3]

3/4

[19.1]

5 7/8

[148.5]

3 7/16

[86.8]

9 7/8

[250.7]

27 3/4

[704.7]

2 5/16

[59]

FRONT OF CASING

TOP OF CASING

4 13/16

[122.2]

27 3/4

[704.7]

5 7/8

[148.5]

8 5/8

[219]

5 1/2

[140.3]

8 7/16

[213.5]

FRONT OF CASING

TOP OF CASING

6.1

[155.7]

2 1/16

[51.6]

5.1

[130.5]

1.7

[43.5]

Ø7/8

[22.2]

ACCESSORY (2)

AIR FLOW

AIR FLOW

BOTTOM RETURN

WIDTH

AIR FLOW

KNOCK OUTS FOR

VENTING(5

PLACES)

A10290

NOTES:

1. Two additional 7/8 ---in. (22 mm) diameter holes are located in the top plate.

2. Minimum return---air openings at furnace, based on metal duct. If flex duct is used, see flex duct manufacturer’s recommendations for equivalent diameters.

(a.) For 800 CFM ---16 ---in. (406 mm) round or 14 1/ 2 x 12 ---in. (368 x 305 mm) rectangle.

(b.) For 1200 CFM---20 ---in. (508 mm) round or 14 1/2 x 19 1/2---in. (368 x 495 mm) rectangle.

(c.) For 1600 CFM---22 ---in. (559 mm) round or 14 1/2 x 22 1/16---in. (368 x 560mm) rectangle.

(d.) For a irflow requiremen ts above 1800 CFM, see Air Del ivery table in Product Data literature for specific use of single side inl ets. The use of both side

inlets, a combination of 1 side a nd the bottom, or the bottom onl y will en sure adequate return air openings for airflow requirements a bove 1800 CFM.

Fig. 1 --- Dimensional Drawing

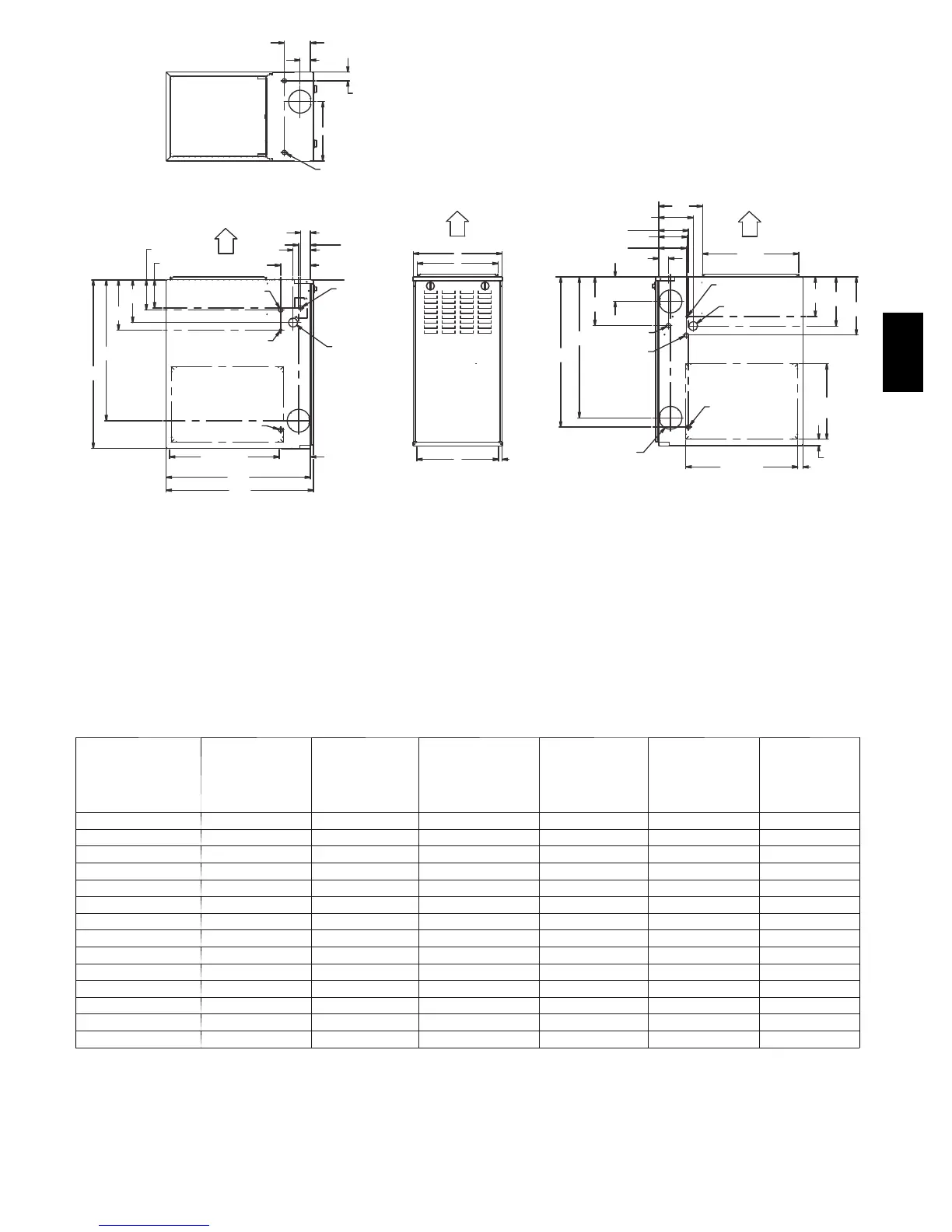

Table 1—Dimensions -- In. (mm)

FURNACE SIZE

A

CABINET

WIDTH

B

OUTLET

WIDTH

C

TOP & BOTTOM

FLUE COLLAR

LOCATION

D

BOTTOM

INLET WIDTH

VENT

CONNECTION

SIZE

SHIP WT

LB (KG)

045---08/024045 14---3/16 (360) 12---9/16 (319) 9---5/16 (237) 12---11/16 (322) 4 (102) 104 (47)

045---12/036045 14---3/16 (360) 12---9/16 (319) 9---5/16 (237) 12---11/16 (322) 4 (102) 107 (49)

070---08/024070 14---3/16 (360) 12---9/16 (319) 9---5/16 (237) 12---11/16 (322) 4 (102) 111 (50)

070---12/036070 14---3/16 (360) 12---9/16 (319) 9---5/16 (237) 12---11/16 (322) 4 (102) 115 (52)

070---16/048070 17---1/2 (445) 15---7/8 (403) 11--- 9/16 (294) 16 (406) 4 (102) 126 (57)

090---14/042090 17---1/2 (445) 15---7/8 (403) 11--- 9/16 (294) 16 (406) 4 (102) 127 (58)

090---16/048090 21 (533) 19---3/8 (492) 13--- 5/16 (338) 19---1/2 (495) 4 (102) 140 (64)

090---20/060090 21 (533) 19---3/8 (492) 13--- 5/16 (338) 19---1/2 (495) 4 (102) 146 (66)

110---12/036110 17---1/2 (445) 15---7/8 (403) 11--- 9/16 (294) 16 (406) 4 (102) 135 (61)

110---16/048110 21 (533) 19---3/8 (492) 13--- 5/16 (338) 19---1/2 (495) 4 (102) 146 (66)

110---22/066110 21 (533) 19---3/8 (492) 13--- 5/16 (338) 19---1/2 (495) 4 (102) 152 (69)

135---16/048135 21 (533) 19---3/8 (492) 13--- 5/16 (338) 19---1/2 (495) 4 (102)* 149 (68)

135---22/066135 24---1/2 (622) 22---7/8 (581) 15--- 1/16 (383) 23 (584) 4 (102)* 163 (74)

155---20/060155 24---1/2 (622) 22---7/8 (581) 15--- 1/16 (383) 23 (584) 4 (102)* 170 (77)

*135 and 155 size furnaces r e quire a 5 or 6---in. (127 or 152 mm) vent. Use a vent adapter between furnace and vent stack. See Installation Instructions for

complete installation requirements.

310AAV

Loading...

Loading...