CAUTION: Connect the gas pipe to the furnace using a

backup wrench to avoid damaging gas controls.

WARNING: Never purge a line into a combustion

chamber. Never use matches, candles, flame, or other

sources of ignition for to check for gas leakage. Use a

soap-and-water solution to check for gas leaks. Failure to

follow this warning could result in fire, explosion, per-

sonal injury, or death.

Joint compounds (pipe dope) should be applied sparingly and only

to the male threads of the joints. This pipe dope must be resistant

to the action of propane gas.

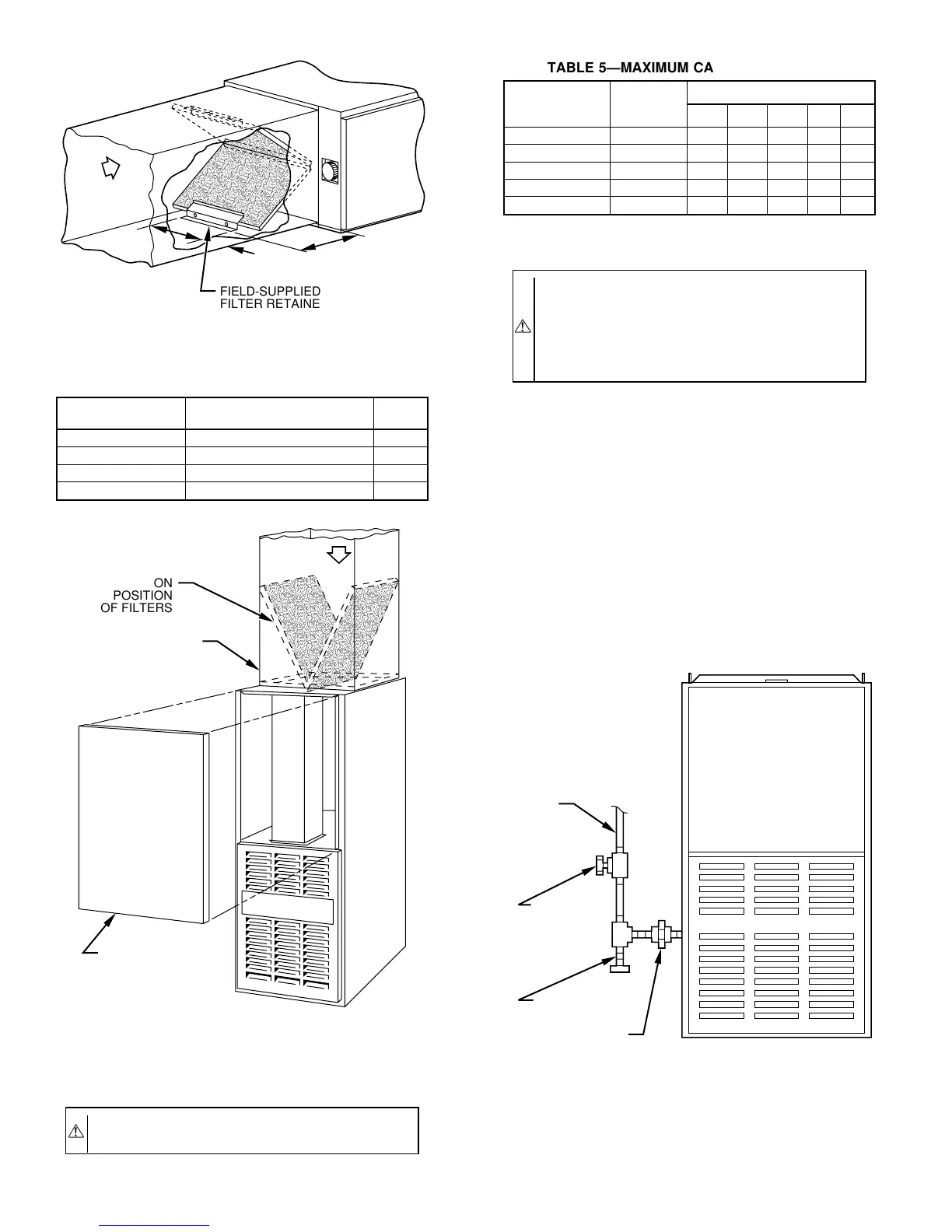

An accessible manual shutoff valve MUST be installed upstream

of the furnace gas controls and within 72 in. of the furnace. A

1/8-in. NPT plugged tapping, accessible for test gage connection,

MUST be installed immediately upstream of the gas supply

connection to the furnace and downstream of the manual shutoff

valve. Place a ground joint union between the gas control manifold

and the manual shutoff.

Install a sediment trap in the riser leading to the furnace. The trap

can be installed by connecting a tee to the riser leading from the

furnace. Connect a capped nipple into the lower end of the tee. The

capped nipple should extend below the level of the gas controls.

(See Fig. 13.)

Piping should be pressure tested in accordance with local and

national plumbing and gas codes before the furnace has been

attached. If the pressure exceeds 0.5 psig (14-in. wc), the gas

supply pipe must be disconnected from the furnace and capped

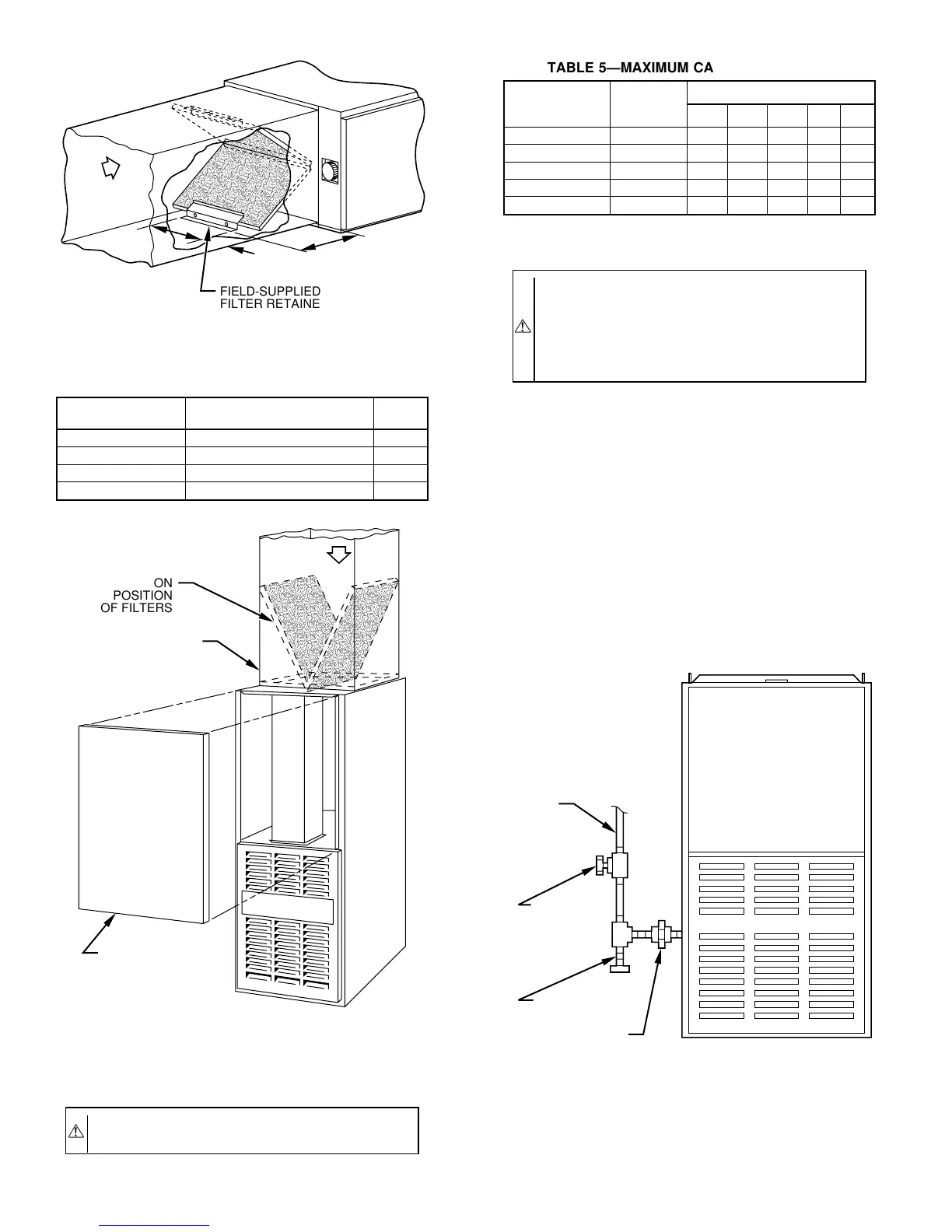

Fig. 11—Horizontal Filter Arrangement

A82173

FIELD-SUPPLIED

FILTER RETAINERS

AIRFLOW

D

12″

4″

TABLE 4—FILTER INFORMATION (IN.)

FURNACE CASING

WIDTH

FILTER SIZE AND QUANTITY D

14-3/16 (2)16X20X1 15–3/8

17-1/2 (2)16X20X1 14–3/4

21 (2)16X20X1 13–3/4

24-1/2 (2)16X20X1 12–1/2

Fig. 12—Downflow Filter Arrangement

A88486

RETURN-AIR

PLENUM

AIRFLOW

ACCESS DOOR

INSTALLATION

POSITION

OF FILTERS

TABLE 5—MAXIMUM CAPACITY OF PIPE*

NOMINAL IRON

PIPE SIZE

(IN.)

INTERNAL

DIAMETER

(IN.)

LENGTH OF PIPE (FT)

10 20 30 40 50

1/2 0.622 175 120 97 82 73

3/4 0.824 360 250 200 170 151

1 1.049 680 465 375 320 285

1–1/4 1.380 1400 950 770 660 580

1–1/2 1.610 2100 1460 1180 990 900

* Cubic ft of gas per hr for gas pressures of 0.5 psig (14-in. wc) or less, and a

pressure drop of 0.5-in. wc (based on a 0.60 specific gravity gas). Ref: Table

10-2 NFPA 54/ANSI Z223.1-1996.

Fig. 13—Typical Gas Pipe Arrangement

A89414

GAS

SUPPLY

MANUAL

SHUTOFF

VALVE

(REQUIRED)

SEDIMENT

TRAP

UNION

—10—

Loading...

Loading...