III. ENTHALPY CONTROL CHECKOUT PROCEDURES

A. Solid-State Enthalpy Control

Use this procedure for the solid-state enthalpy control that

comes standard with the economizer. (See table below.)

Solid-State Enthalpy Control Contents

PART NO.

HF25CA003

Economizer Motor

Economizer Logic Module

HH57AC078 Solid-Stage Enthalpy Sensor

HH79AZ001 Mixed-Air Sensor

1. Disconnect power at terminals TR and TR1. Dis-

connect jumper across terminals P and P1.

2. Jumper terminals TR and 1.

3. Connect enthalpy sensor to terminals SO and +. The

factory-installed 620-ohm resistor should be in place

on terminals SR and +.

4. Turn enthalpy set point to ‘‘A.’’

5. Jumper terminal T to terminal T1.

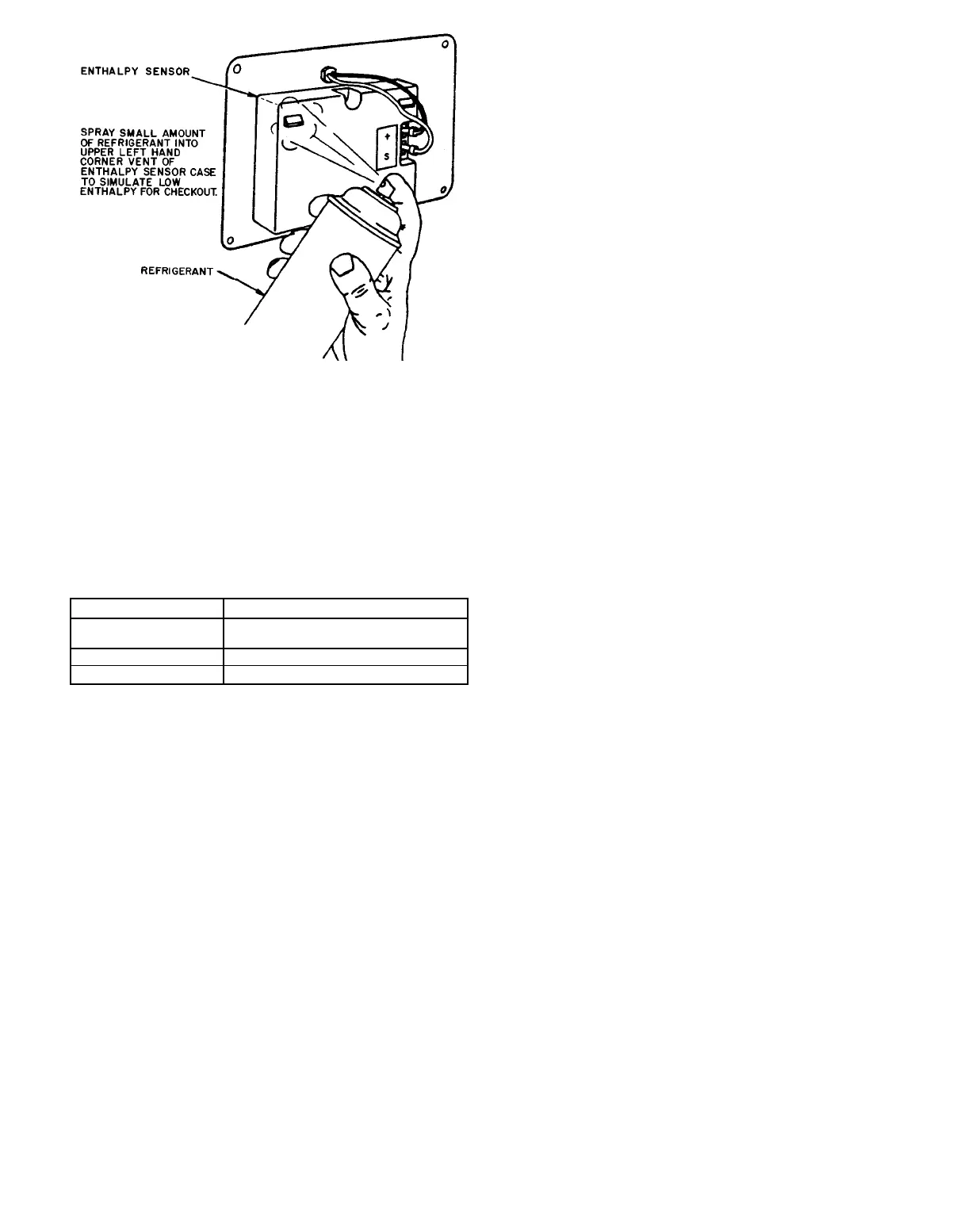

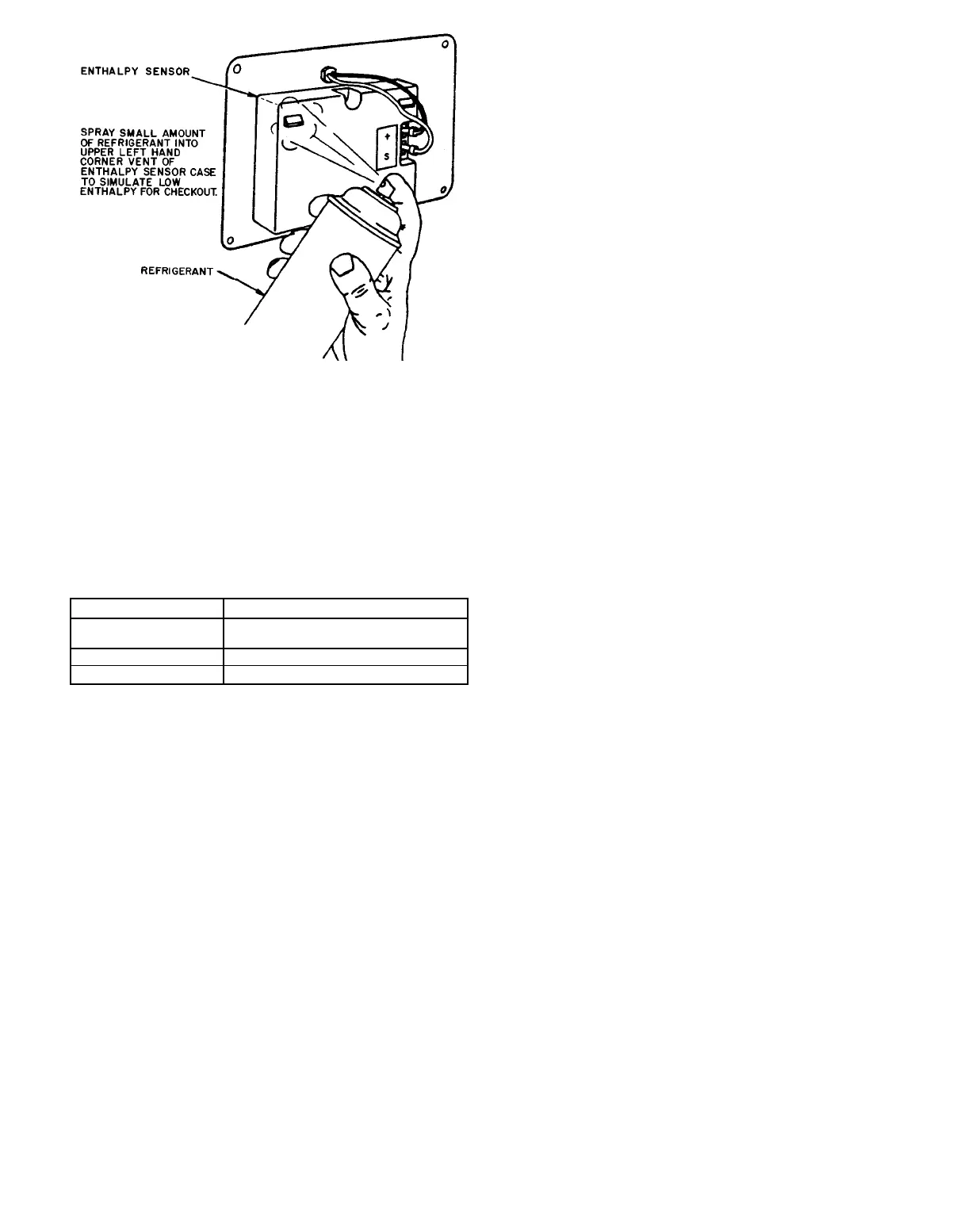

6. Spray a small amount of refrigerant in the upper left

vent of the enthalpy sensor to simulate low enthalpy

conditions. (See Fig. 15.)

7. Connect 24-v power at terminals TR and TR1. The LED

(light-emitting diode) will turn on and the economizer

motor will drive the damper full open.

8. Disconnect the jumper at terminals T and T1. The econo-

mizer motor will drive the damper full closed.

9. Connect a jumper across terminals P and P1.

10. Turn minimum position potentiometer adjustment coun-

terclockwise and the economizer motor drives the damper

closed.

11. Turn minimum position potentiometer adjustment clock-

wise and the economizer motor drives the damper open.

12. Disconnect the power at terminals TR and TR1. The

economizer motor spring-returns the damper to closed

position.

B. Differential Enthalpy Control

Use this checkout procedure for the accessory differential

enthalpy control. The differential enthalpy control kit con-

tains one solid-state enthalpy sensor (part no. HH57AC078)

to be installed in addition to the solid-state enthalpy control

which comes standard with the economizer. See table on

this page for standard solid-state enthalpy control package

contents.

1. Disconnect the power at terminals TR and TR1. See

Fig. 12.

2. Disconnect the jumper across terminals P and P1.

3. Disconnect the factory-installed 620-ohm resistor.

4. Connect one enthalpy sensor to terminals SO and +.

5. Connect the other enthalpy sensor to terminals SR

and +.

6. Turn the enthalpy set point past the ‘‘D’’ setting (fully

clockwise).

7. Connect a jumper across terminals T and T1.

8. Spray a small amount of refrigerant in upper left vent

of enthalpy sensor connected to SO and + to simulate

low outdoor-air enthalpy. (See Fig. 15.)

9. Reconnect power at terminals TR and TR1. The LED

(Light-emitting diode) turns on, and the economizer

motor drives the damper open.

10. Spray a small amount of refrigerant in upper left vent

of enthalpy sensor connected to SR and + to simulate

low return-air enthalpy. (See Fig. 15.) The LED turns

off, and the economizer motor drives the damper closed.

Fig. 15 — Use of Refrigerant Spray on Sensor to

Simulate Low Enthalpy

—7—

Loading...

Loading...