VII. MAKE ELECTRICAL CONNECTIONS

WARNING: To avoid personal injury or death, do not

supply power to unit with compressor terminal box cover

removed.

Be sure field wiring complies with local and national fire, safety,

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device.

NOTE: Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage may fluctuate above or below

permissible limits.

NOTE: Use copper wire only between disconnect switch and

unit.

NOTE: Install branch circuit disconnect of adequate size per

NEC to handle unit starting current. Locate disconnect within sight

from and readily accessible from unit, per Section 440-14 of NEC.

A. ROUTE GROUND AND POWER WIRES

Remove access panel to gain access to unit wiring. Extend wires

from disconnect through power wiring hole provided and into unit

control box. Size wires per NEC but not smaller than minimum

wire size shown in Product Data Sheet.

WARNING: The unit cabinet must have as uninter-

rupted or unbroken ground to minimize personal injury if

an electrical fault should occur. The ground may consist

of electrical wire or metal conduit when installed in

accordance with existing electrical codes. Failure to

follow this warning can result in an electric shock, fire, or

death.

B. CONNECT GROUND AND POWER WIRES

Connect ground wire to ground connection in control box for

safety. Connect power wiring to leads provided as shown in Fig. 8.

C. CONNECT CONTROL WIRING

Route 24v control wires through control wiring grommet and

connect to leads provided in control box. (See Table 3 and Fig. 9.)

Use No. 18 AWG color-coded, insulated (35°C minimum) wire. If

thermostat is located more than 100 ft from unit, as measured

along the control voltage wires, use No. 16 AWG color-coded wire

to avoid excessive voltage drop.

All wiring must be NEC Class 1 and must be separated from

incoming power leads.

The outdoor unit requires a minimum of 27va, 24vac control

power.

IMPORTANT: Check factory wiring and wire connections to

ensure terminations are secured properly. Check wire routing to

ensure wires are not in contact with tubing, sheet metal, etc.

VIII. INSTALL ELECTRICAL ACCESSORIES

A. GENERAL

Refer to the individual instructions packaged with kits or acces-

sories when installing.

Available electrical accessories include latent capacity control. See

Table 3 and Fig. 9 for typical accessory wiring diagrams.

B. LATENT CAPACITY CONTROL (LCC)

The purpose of an LCC is to provide a dehumidification mode to

assure a 75 percent or less system sensible heat ratio. If indoor unit

installed contains an ICM blower (such as an FK4C or FV4A fan

coil or a 333(B,J)AV or 355MAV gas furnace), no LCC is

required. Indoor products with ICM blowers have enough CFM

range to provide proper airflow for low-speed cooling. If indoor

unit installed has a standard PSC blower motor, the low-speed

airflow available is too great to assure 75 percent or less system

sensible heat ratio. The LCC for standard blower products consists

of a standard humidistat which opens contacts on humidity rise and

a pilot duty relay with 24v coil.

NOTE: If an LCC is desired, low-speed airflow must be main-

tained so that a minimum of 300 CFM/ton can be supplied during

high-speed LCC operation.

LCC OPERATION FOR TYPICAL PSC FAN COILS

The standard blower operation for systems with typical PSC fan

coils is covered in Fig. 9A, B, and D. The blower runs in high

speed regardless if compressor operation is high or low speed.

When the LCC is wired according to Fig. 9A, B, or D and humidity

rises, the humidistat contacts open and de-energize the relay. If

relay is de-energized, the system operates on high-speed compres-

sor and high-speed airflow until humidistat closes. Fig. 9C shows

the wiring with a Bryant Thermidistat which controls temperature

and humidity level without the need for an additional humidistat

and relay.

LCC OPERATION FOR TYPICAL PSC FURNACES

The standard blower operation of systems with typical PSC

furnaces is covered in Fig. 9J, K, M, N, P, and R. The blower runs

in high or low speed in conjunction with compressor high- or

low-speed operation. When the LCC is wired according to Fig. 9K,

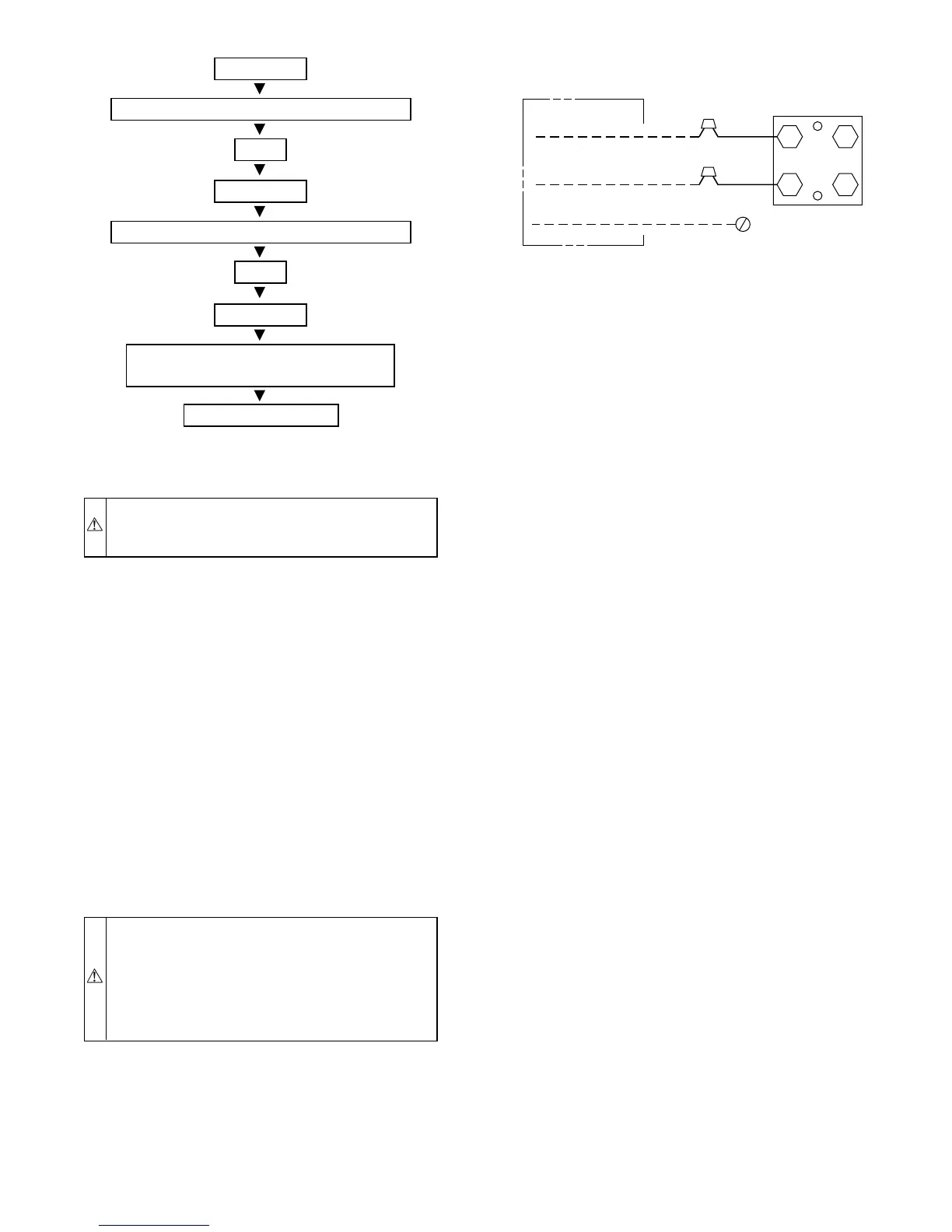

Fig. 7—Triple Evacuation Method

A95425

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

CHARGE SYSTEM

BREAK VACUUM WITH DRY NITROGEN

EVACUATE

WAIT

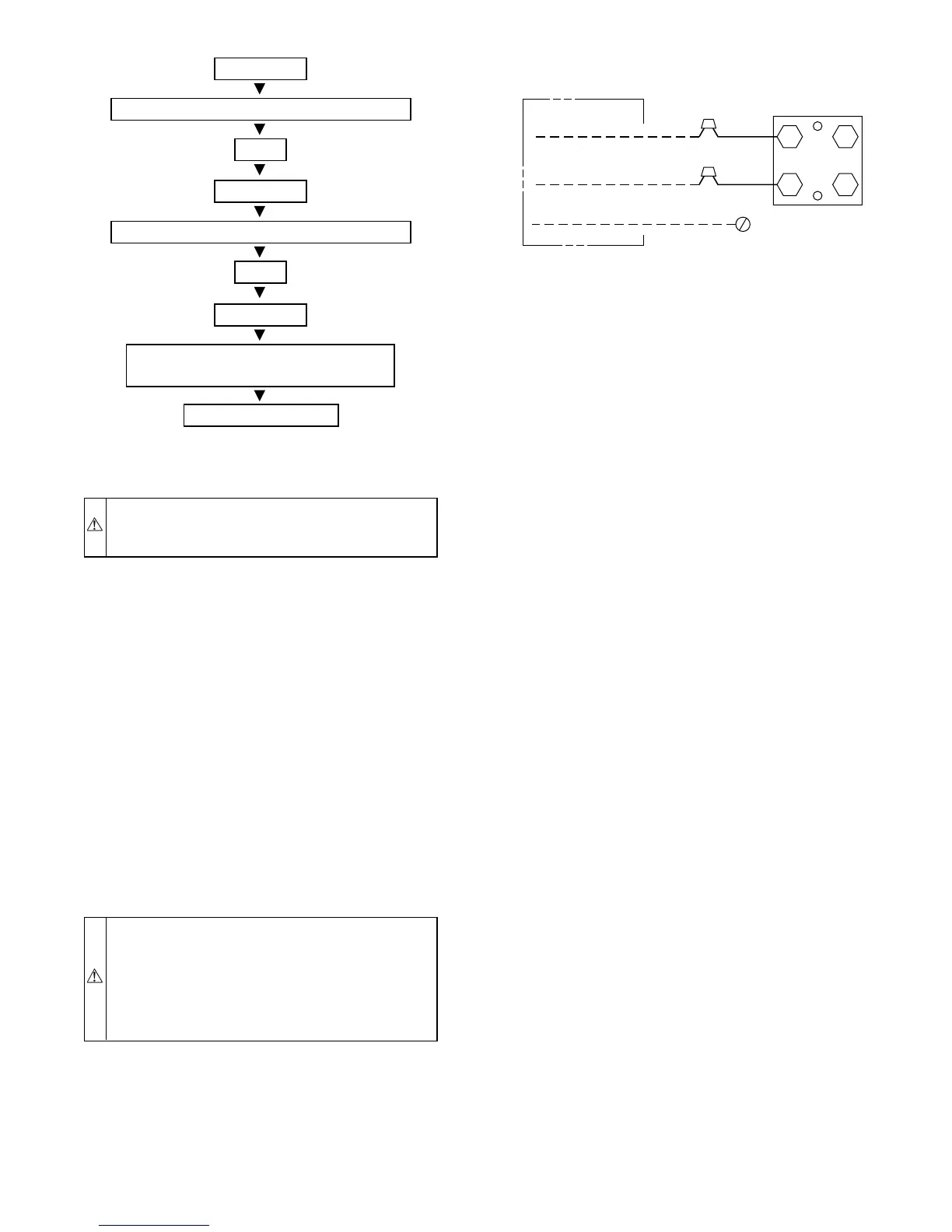

Fig. 8—Line Power Connections

A91306

CONTACTOR

DISCONNECT

PER N. E. C. AND/ OR

LOCAL CODES

FIELD POWER

WIRING

FIELD GROUND

WIRING

GROUND

LUG

—5—

Loading...

Loading...