Increased Demand for Cooling

NOTE: There are 2 separate compressor circuits in the

538S

_

048 units (circuit A and circuit B). Each circuit oper-

ates independently, and will operate as follows (as will the

single-circuit 024 units) upon receiving the first 24-v cooling

demand signal from a fan coil unit:

1. After the 2-minute time-delay function is satisfied, the

appropriate compressor starts.

2. The solenoid valve connected to the fan coil sending the

demand signal is energized (at the 538S units).

3. The outdoor fan starts, and its operation is controlled

by the microprocessor as described in 538S Microproces-

sor Control of Outdoor Fan section below.

When a second fan coil unit signals a demand for cooling, its

associated solenoid valve is energized immediately, allowing

refrigerant to flow to both fan coil units simultaneously.

Decreased Demand for Cooling

When a fan coil unit’s demand for cooling ends, the 24-v sig-

nal to the 538S unit stops, and the appropriate solenoid valve

closes. If the other fan coil unit on this circuit still has a de-

mand, the appropriate compressor will continue to run as long

as necessary for the second fan coil unit.

When the second fan coil unit’s demand for cooling ends, its

solenoid valve closes, and the appropriate compressor stops.

The compressor will not start for at least 2 minutes after the

end of this cycle due to the time-delay function.

On size 024 units, when the compressor stops, the outdoor

fan also stops. On size 048 units, outdoor fan operation may

continue under control of the 538S microprocessor if the other

refrigerant circuit is still operating. The outdoor fan will only

stop when both compressors are off. Refer to 538S Micro-

processor Control of Outdoor Fan section below for more

details.

C. 538S Microprocessor Control of Outdoor Fan

The microprocessor control has a built-in head pressure con-

trol system that will cycle the outdoor-fan motor to maintain

a selected discharge pressure. The microprocessor senses out-

door ambient temperature using a thermistor and refriger-

ant pressure using a pressure transducer mounted on the

compressor circuit discharge line. The 538S

_

024 units have

one transducer, and the 048 units have two.

The factory set points for the head pressure control opera-

tion are 55 F for outdoor ambient temperature and 250 psig

for discharge pressure.

When the outdoor ambient temperature is above the outdoor

ambient set point and both fan coils on a compressor circuit

are calling for cooling operation, the outdoor fan will run at

full speed whenever compressor operation is permitted. When

only one fan coil on a circuit is calling for cooling, fan cycling

is permitted at all ambients. Fan motor will be cycled on and

off to maintain set point discharge pressure.

When the outdoor ambient temperature is below the speci-

fied set point, the fan motor will be cycled on and off to main-

tain a compressor discharge pressure at the specified pres-

sure set point. On 538S

_

048 units with 2 compressors running,

the compressor with the lower head pressure will control the

fan operation. If only one compressor is running, that com-

pressor will control the fan operation.

If the discharge pressure on either circuit exceeds 370 psig,

the outdoor-fan motor will run continuously, and the fan cy-

cling function will be bypassed until the discharge pressure

decreases to 365 psig.

Units can be field configured to select head pressure control

at 35 F outdoor ambient and/or 200 psig discharge pressure.

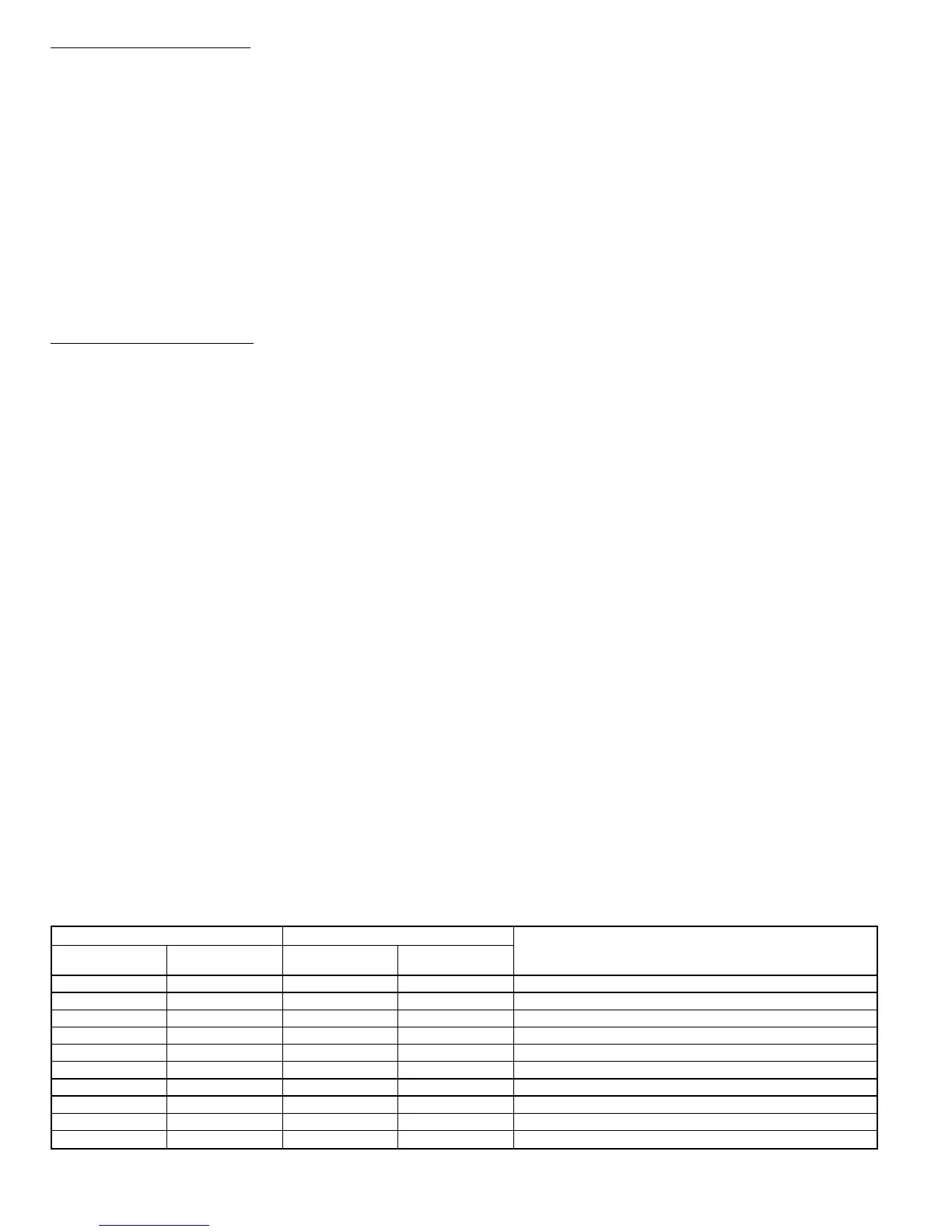

D. Status Indicator Lights

The 538S control board is equipped with LED indicators to

aid in evaluating the status of the control system, including

(see Table 3):

• time delay function status

• fan coil unit demand status

• head pressure control status

• current unit malfunctions

E. Unit Malfunction

Each compressor circuit is equipped with a high-pressure switch

(HPS), a loss-of-pressure switch (LPS), and a discharge tem-

perature switch (DTS). These safety devices are located in a

Cycle-LOC™ device circuit that prevents compressor opera-

tion if any of these safety devices is activated. The lockout

can be reset by turning the main power to the 538S unit off,

then on again.

Compressor overcurrent protection is achieved by an inter-

nal linebreak overload, which will automatically reset when

the motor temperature cools to a satisfactory level. Manual

reset of Cycle-LOC circuit may also be required (turn main

unit disconnect to OFF, then to ON position).

Pressure transducers and the outdoor ambient thermistor are

monitored by the 538S controller. If a pressure transducer is

found to be out of range, the LEDs will flash a code for this

fault, but the control will continue to cycle the outdoor fan

according to input from the other transducer. If only one trans-

ducer is active and is determined to be out of range, the head

pressure control will be bypassed and the fan will run con-

tinuously. If the thermistor is found to be out of range, the

control will allow fan cycling per transducer input, and the

LEDs will flash a code for this failure. See Table 3.

Table 3 — System Status Red and Green LEDs and Fault Codes

GREEN LED RED LED

UNIT STATUS

Number of

Flashes On

Number of

Flashes Off

Number of

Flashes On

Number of

Flashes Off

1 1 — Always Off System Ready

1111 LowHead Pressure, Circuit 1

1122 High Head Pressure, Circuit 1

1133 LowHead Pressure, Circuit 2

2211 High Head Pressure, Circuit 2

2222LowOutdoor Ambient Temperature, Outdoor Thermistor

2233High Outdoor Ambient Temperature, Outdoor Thermistor

3311 Hardware Error

3322 TimeGuardT Device Active, Circuit 1

3333 TimeGuard Device Active, Circuit 2

LED — Light-Emitting Diode

—14—

Loading...

Loading...