IV. COMPLETE REFRIGERANT PIPING

NOTE: Complete all refrigerant tubing connections at the fan

coil units first. Then route the tubing sets back to the out-

door unit. Mark each tubing set carefully to identify its re-

spective fan coil unit.

Outdoor units may be connected to indoor units using field-

supplied tubing of refrigerant grade and condition. See

Table 1 for correct line sizes. Do not use less than 10 ft

of interconnecting tubing.

NOTE: It is not necessary to make any changes to line sizes

or any refrigerant system modifications when using recom-

mended refrigerant line lengths.

When installing tubing, both the vapor return line and the

vapor supply (smaller) line must be insulated between out-

door unit and indoor unit to avoid condensation on the lines.

Use closed-cell foam insulation and tape all seams and joints.

CAUTION:

DO NOT BURY MORE THAN 36 IN. OF

REFRIGERANT TUBING IN THE GROUND. If any sec-

tion of tubing is buried, there must be a 6-in. vertical

rise to the valve connections on the outdoor unit. If more

than the recommended length is buried, refrigerant may

migrate to cooler, buried section during extended peri-

ods of system shutdown. This causes refrigerant slug-

ging and could possibly damage compressor at start-

up.

DO NOT USE MORE THAN 50 FT of EQUIVALENT

interconnecting tubing or more than 30 ft of VERTI-

CAL lift (see Fig. 7) between the lowest system compo-

nent and the highest system component.

If either refrigerant tubing or indoor coil is opened to atmo-

spheric conditions for longer than 5 minutes, it must be evacu-

ated to 1000 microns to eliminate contamination and mois-

ture in the system.

Run refrigerant tubes as directly as possible, avoiding un-

necessary turns and bends. Suspend refrigerant tubes so they

do not damage insulation on vapor return or supply tubes

and do not transmit vibration to structure. Also, when pass-

ing refrigerant tubes through wall, seal opening so that vi-

bration is not transmitted to structure. Leave some slack in

refrigerant tubes between structure and outdoor unit to ab-

sorb vibration. See Fig. 5 for indoor to outdoor unit tubing

connections, and refer to separate indoor fan coil unit instal-

lation instructions for additional information.

NOTE: If only 2 fan coil units are used on 538S

_

048 sys-

tems, be sure that one is used with each compressor refrig-

erant circuit. If 2 or 3 fan coil units are used, cap any unused

refrigerant lines at the service valves.

WARNING:

DO NOT INSTALLAFIELD-SUPPLIED

FILTER DRIER in this system. Filter drier is factory

installed inside the outdoor unit. Installing a filter drier

in the liquid line between the indoor and outdoor units

will cause a high-pressure drop, and will result in ab-

normal system operation.

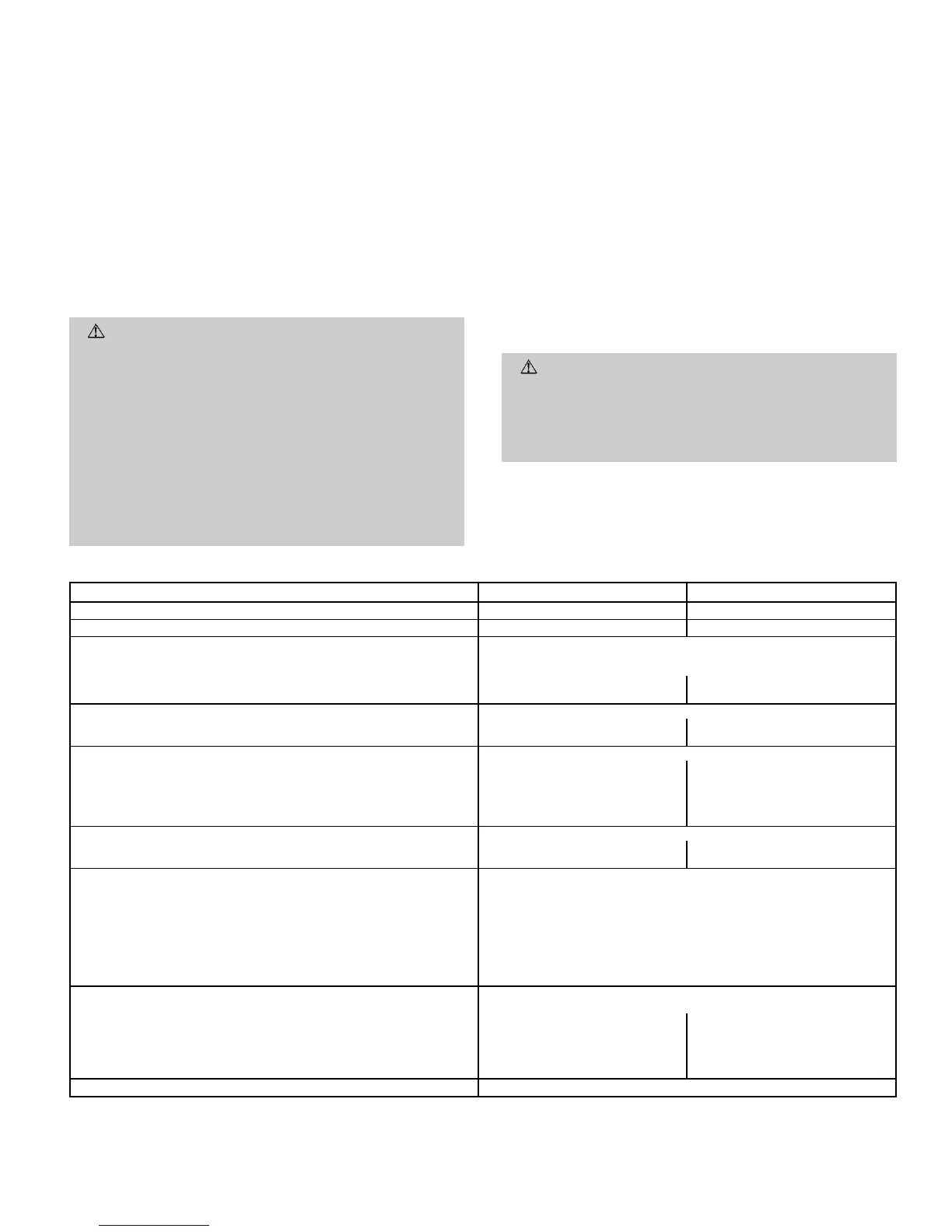

Table 1 — Specifications

UNIT 538S

_

024 048

NOMINAL CAPACITY (Tons) 24

OPERATING WEIGHT (lb) 159 292

REFRIGERANT TYPE R-22

Control (Cooling) TXV in Condensing Unit

Factory Charge (lb)*

Circuit A 5.0 5.5

Circuit B — 5.5

COMPRESSOR TYPE Copeland Scroll

Quantity...Model 1...ZR23K1 2...ZR49K3

Oil (Recharge) (oz) 25 53

OUTDOOR FAN Propeller, Direct Drive

Rpm 850 850

Diameter (in.)...No. of Blades 18...3 24...3

Pitch (Degrees) 27 24

Motor Hp

1

⁄

8

1

⁄

4

Nominal Air Cfm 1720 3900

OUTDOOR COIL Copper Tube, Aluminum Fin

Face Area (sq ft)...No. of Rows 6.1...2 12.3...2

Fins/in. 15 15

CONTROLS

High-Pressure (psig)

Cut-in 320±20

Cutout 426 ± 7

Low-Pressure (psig)

Cut-in 22 ± 5

Cutout 7± 3

Fusible Plug 210 F

Control Voltage 24

REFRIGERANT LINES

Connection Type Sweat

Vapor Supply Line Quantity...OD (in.) 2...

3

⁄

8

2†...

3

⁄

8

Vapor Return Line Quantity...OD (in.) 2...

5

⁄

8

2†...

7

⁄

8

Maximum Length (ft) 50 50

Maximum Lift (Fan Coil Above Outdoor) (ft) 30** 30**

Maximum Lift (Fan Coil Below Outdoor) (ft) 30** 30**

EXTERNAL FINISH Alpine Mist (Beige)

LEGEND

TXV — Thermostatic Expansion Valve

*Charge is based on 25 ft of interconnecting line.

†Per circuit.

**Maximum system lift is 30 ft between lowest system component and

highest system component.

—7—

Loading...

Loading...