1. Install suction tube adapter.

2. Install liquid flare-to-sweat adapter.

3. Connect external equalizer tube to fitting on suction tube

adapter.

4. Position sensing bulb on horizontal portion of suction tube

adapter. Secure using supplied hardware.

5. Insulate bulb after installation. (See Fig. 6.)

6. Leak check all connections.

B. Fan Coils

If indoor unit (fan coil) comes factory equipped with a bi-flow

hard shutoff TXV specifically designed for Puron, no TXV change

is required.

If TXV installation is required, refer to TXV kit Installation

Instructions for details on TXV installation.

VII. CHECK DEFROST THERMOSTAT

Check defrost thermostat to ensure it is properly located and

securely attached. There is a liquid header with a brass distributor

and feeder tube going into outdoor coil. At the end of 1 of the

feeder tubes, there is a 3/8-in. OD stub tube approximately 3 in.

long. (See Fig. 7.) The defrost thermostat should be located on stub

tube. Note that there is only 1 stub tube used with liquid header,

and on most units it is the bottom circuit.

VIII. IN LONG-LINE APPLICATIONS, INSTALL LIQUID-

LINE SOLENOID VALVE (LSV)

For refrigerant piping arrangements with equivalent lengths

greater than 50 ft and/or when elevation difference between indoor

and outdoor unit is greater than ± 20 ft, follow all requirements of

the Long-Line Guideline section in the Application Guideline and

Service Manual for Residential Split-System Air Conditioners and

Heat Pumps Using Puron Refrigerant.

If required by Long-Line Application Guideline, install LSV kit

Part No. KHALS0401LLS specifically designed for Puron Heat

Pump. LSV should be installed within 2 ft of outdoor unit with

flow arrow pointing toward outdoor unit. Follow the Installation

Instructions included with accessory kit.

IMPORTANT: Flow arrow must point toward outdoor unit.

IX. MAKE PIPING CONNECTIONS

WARNING: Relieve pressure and recover all refrigerant

before system repair or final unit disposal to avoid

personal injury or death. Use all service ports and open all

flow-control devices, including solenoid valves.

CAUTION: Do not leave system open to atmosphere

any longer than minimum required for installation. POE

oil in compressor is extremely susceptible to moisture

absorption. Always keep ends of tubing sealed during

installation.

CAUTION: If ANY refrigerant tubing is buried, provide

a 6 in. vertical rise to the valve connections at the unit. Do

NOT bury refrigerant tubing lengths greater than 36 in.

CAUTION: To prevent damage to unit or service valves

observe the following:

• Use a brazing shield.

• Wrap service valves with wet cloth or use a heat sink

material.

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct

size and condition. For tubing requirements beyond 50 ft, substan-

tial capacity and performance losses can occur. Follow the

recommendations in the Application Guideline and Service

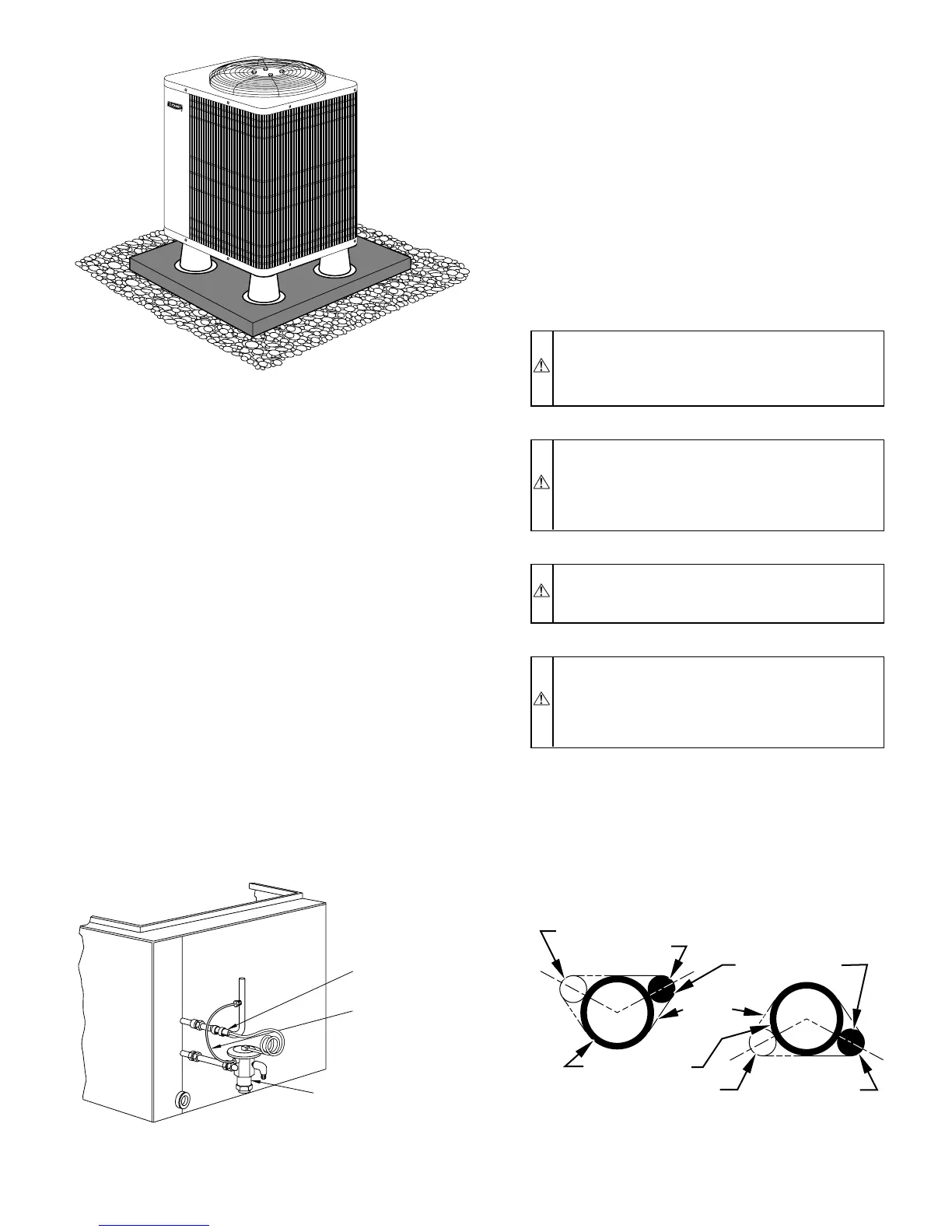

Fig. 4—Accessory Support Feet

A98532

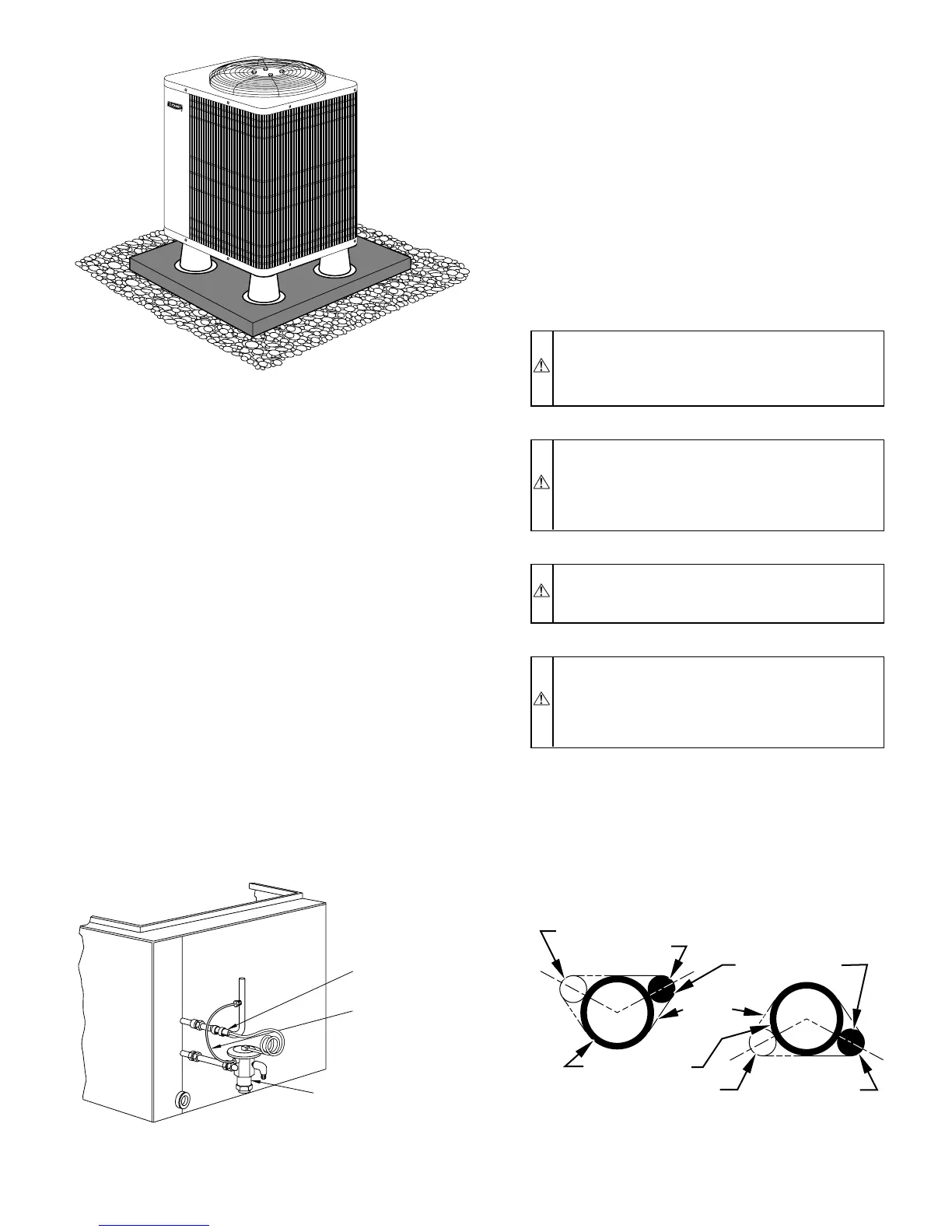

Fig. 5—Typical TXV Installation

A91277

THERMOSTATIC

EXPANSION

VALVE

EQUALIZER

TUBE

SENSING

BULB

COIL

Fig. 6—Positioning of Sensing Bulb

A81032

2 O'CLOCK

10 O'CLOCK

SENSING BULB

STRAP

SUCTION TUBE

8 O'CLOCK

4 O'CLOCK

7

⁄

8

IN. OD & SMALLER

LARGER THAN

7

⁄

8

IN. OD

—3—

Loading...

Loading...