20

Status Codes

Unit may occasionally become unresponsive due to certain

combinations of previous fault codes. There may not be

anything wrong with the unit or components. The unit may

require a high voltage power cycling for at least 2 minutes or

longer to clear the condition. If the condition persists, conduct

further troubleshooting per Service Manual.

ATTENTION

!

Table 7 shows the status codes flashed by the amber status light.

Most system problems can be diagnosed by reading the status code

as flashed by the amber status light on the control board.

The codes are flashed by a series of short and long flashes of the

status light. The short flashes indicate the first digit in the status

code, followed by long flashes indicating the second digit of the

error code.

The short flash is 0.25 seconds ON and the long flash is 1.0 second

ON. Time between flashes is 0.25 seconds. Time between short

flash and first long flash is 1.0 second. Time between code

repeating is 2.5 seconds with LED OFF.

Codes are easily read from user interface (UI)

EXAMPLE:

3 short flashes followed by 2 long flashes indicates a 32 code.

Table 7 shows this to be low pressure switch open.

Status Code Recall Mode

Active status codes are stored in memory even when power is

absent. The most recent flashing status code (highest priority

active) can be recalled from memory via Status Code Recall Mode

and displayed using the amber LED. The Status Code Recall

Mode is accessed by shorting (use a clip wire) the “force defrost”

connector (labeled J2 on the board) and then power ON the unit.

Please make sure the unit is turned OFF before shorting the pins.

Status Code Recall Mode will continue as long as the “force

defrost” terminals remain shorted. The unit will not attempt to heat

or cool while the terminals remain shorted. Once the status code is

read, power--down the unit and remove the short.

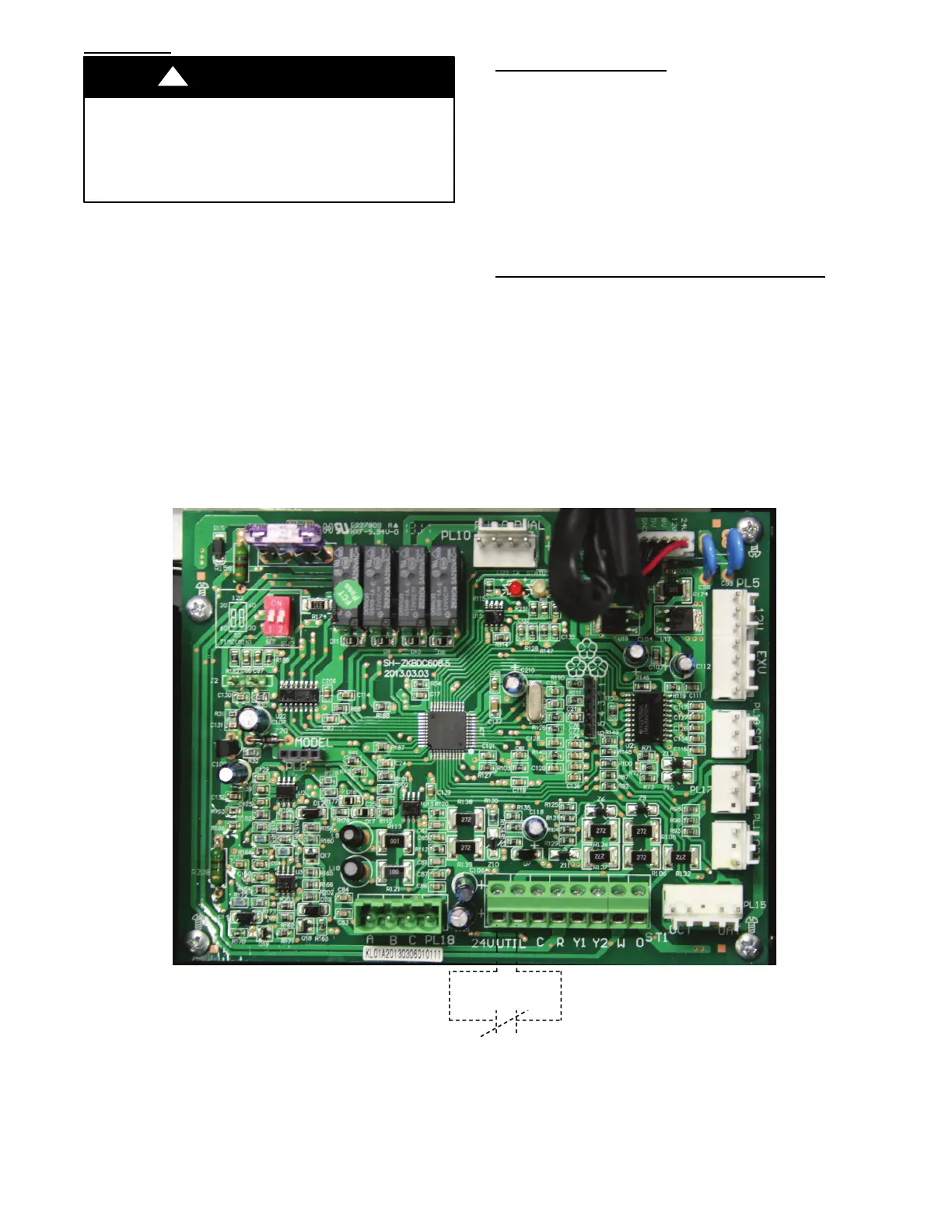

Utility Interface With Evolution Connex Control

The utility curtailment relay should be wired between the two

UTIL connections on the control board for this Evolution

Communicating System (see Fig. 41). This input allows a power

utility device to interrupt compressor operation during peak load

periods. When the utility sends a signal to shut the system down,

the User Interface status screen will display , ”Curtailment Yes”.

See UI installation instructions for setup details.

Utility Relay

A13414

Fig. 41 -- Variable Speed Control Board with optional Utility Relay

Loading...

Loading...