8

Step 8 — Compressor Crankcase Heater

This compressor has an internal crankcase heater. Furnish power

to the unit a minimum of 24 hr before starting the unit for the first

time.

Upon initial start--up of unit, status code 68 will be generated and

system will operate at stage 2 for 11 minutes. This operation is

important to system reliability and cannot be bypassed. Each time

high voltage is removed and reapplied this behavior will be

repeated.

To furnish power to heater only, set thermostat to OFF and close

electrical disconnect to outdoor unit.

Power is not required to the indoor unit or User Interface for proper

operation of heater. Crankcase heater will be intelligently

energized as needed between operations, even when the UI or

thermostat and indoor unit is not installed, as long as there is power

to the outdoor unit.

Airflow Setup for Evolution Connex Control

Furnace or FE Fan Coil (communicating)

This system can only be installed with Evolution --capable indoor

and Evolution Connex User Interface (UI) SYSTXBBECC01,

SYSTXBBECW01 or SYSTXBBECN01 with version 11 software

or newer. Version 12 or newer software required on model size 13.

When using an Evolution Connex User Interface, airflow is

automatically selected based on equipment size. The user has the

option of selecting Comfort, Efficiency and Max airflow for

Heating and/or Cooling modes. These should be selected based on

balance between the homeowner’ s comfort and ener gy

consumption expectations. See User Interface Installation

Instructions for additional available adjustments.

Due to using a communicating control with the fan coil or the

furnace, dip switch adjustments are not necessary. The outdoor

unit configuration and the indoor airflows are determined by

communicating control setup.

Airflow Setup for Non--communicating Fan Coil

The system can be installed with a standard 2--stage heat pump

thermostat and FV4C fan coil without additional accessories.

Select appropriate unit size on fan coil Easy select board.

For replacement applications with older FV4(A,B), FK4 and 40FK

fan coils, the model plug in the outdoor unit must be changed per

Table 2 below.

The model plug adjusts compressor speed to match available low

stage indoor airflow.

NOTE: 288BNV013 is AHRI rated with communicating indoor

units only due to low stage airflow requirements.

Table 2 – Alternate Model Plug

FV4(A,B), FK4, 40FK Fan Coil Models*

(Requires outdoor model plug change)

288BNV

Factory

Model Plug #

HK70EZ***

Required Acce ssory

Model Plug #

HK70EZ***

024 009 015

025 001 016

036 002 017

048 003 018

060 004 019

* FK4 and 40FK also require a TXV change. See accessory list for approved TXV.

Airflow Setup for Non--communicating Furnaces

For installations with non--communicating furnaces, set airflows to

350--400 cfm/nominal ton in high stage and 70--80 percent of high

stage airflow in low stage.

Step 9 — Install Accessories

No refrigeration circuit accessories are required or are available for

installation within the unit. External to the unit, the same

accessories such as support feet, snow rack, wind baffle etc.,

available on other Bryant units, can also be used on this line of

product. For models utilizing 23 inch x 23 inch base pans, it is

recommended to use 5 support feet in order to fully support unit.

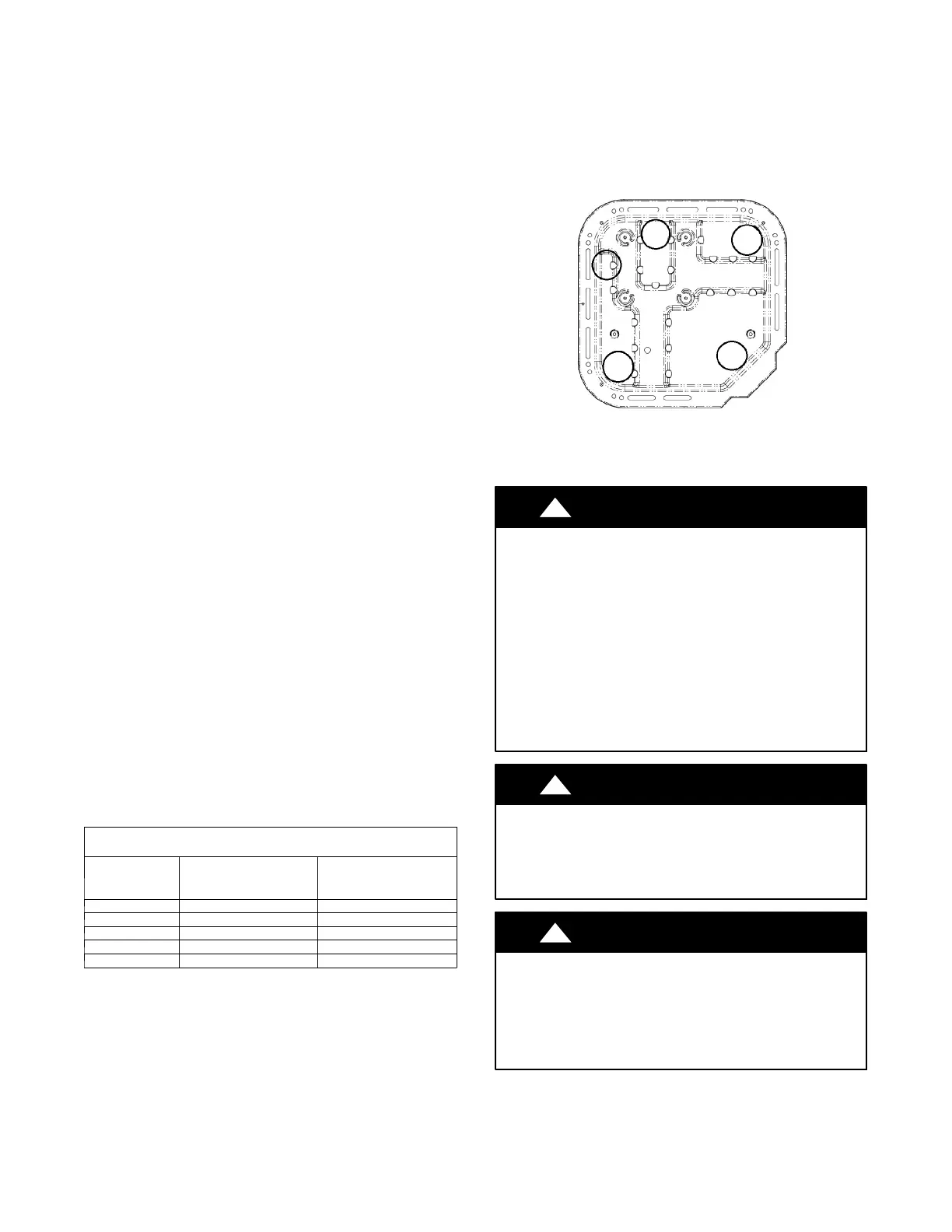

See Fig. 8. Refer to the individual Installation Instructions

packaged with kits or accessories when installing.

A14008

Fig. 8 -- Recommended Support Feet Location

(for 23” x 23” basepan)

Step 10 — Start--Up

CAUTION

!

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this caution may result in minor personal

injury, equipment damage or improper operation.

Observe the following:

1.Do not overcharge system with refrigerant.

2.Do not operate unit in a vacuum or at negative pressure.

3.Do not disable low pressure transducer or system safety

devices such as discharge thermistor or the high pressure

switch.

4.Dome temperatures may be hot.

5.Discharge thermistor is engaged tight on the discharge tube.

CAUTION

!

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

Wear safety glasses, protective clothing, and gloves when

handling refrigerant.

CAUTION

!

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental

damage.

Federal regulations require that you do not vent refrigerant to

the atmosphere. Recover during system repair or final unit

disposal.

Loading...

Loading...