NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

INTRODUCTION..........................................................................1

OVERVIEW OF ZONING............................................................1

WHAT IS ZONING?.....................................................................1

IS A ZONING SYSTEM RIGHT FOR THIS JOB?....................1

DESIGNING A ZONE PERFECT PLUS INSTALLATION ......1

ASSIGNING ZONES...............................................................2

SIZING THE EQUIPMENT ....................................................3

SIZING THE DUCT SYSTEM ...............................................3

REFERENCE FOR DUCT SIZING WORKSHEET:

STEP 6 ......................................................................................4

REFERENCE FOR DUCT SIZING WORKSHEET:

STEP 7 ......................................................................................5

APPENDIX ....................................................................................5

INTRODUCTION

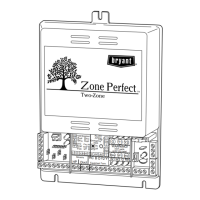

Zone Perfect Plus is a zoning system capable of providing zone

control requirements for 2, 4, or 8 living or business areas. This

system allows the home or business owner to control the living

environment in an individualized way. The Zone Perfect Plus kit

includes the User Interface, Equipment Controller, Remote Sen-

sors, an Outdoor Temperature Sensor, and Leaving Air Tempera-

ture (LAT) Sensor. See Fig. 1 for components which make up an

8–zone kit.

This guide provides information to help you design a Zone Perfect

Plus installation. It discusses general topics related to designing a

zoning control system.

Use this guide to help you design a zoning system that will:

• Meet or exceed the expectations regarding the system’s capa-

bilities. This goal will result in improved customer perception

of your company, as well as repeat business and referrals.

• Protect the heating and cooling equipment used in the system.

This goal will result in improved system reliability, longer life

of heating and cooling equipment, and reduced warranty costs.

To design a zoning system to perform well under all conditions, it

is essential to view the system as a whole at the design stage, rather

than to begin selecting and installing individual components

without a careful assessment of how they will work together. Be

sure to perform all of the Tasks described in this guide before you

begin to install components.

OVERVIEW OF ZONING

Zoning systems bring the possibility of total comfort control to the

occupants by providing the right amount of heating or cooling to

each space. Comfort can be described as the absence of sensation.

Ideally, a zoning system should keep the occupants of the space

comfortable without them being aware of the system.

WHAT IS ZONING?

A zone is a conditioned space (one room or a group of rooms) that

is separately controlled by its own sensor. There are as many

sensors in a designed system as there are zones.

A zoning system is a heating and cooling control system that

maintains each zone at a predetermined temperature set point and

maintains the overall space at a predetermined humidity set point.

In addition to meeting these basic goals, Zone Perfect Plus is

designed to:

• Direct conditioned air proportionately based on the needs of

each zone, so that the zone(s) with the greatest demand receive

relatively more conditioned air.

• Keep the sound produced by the system low enough that

occupants will not find it objectionable.

• Conveniently interface with and protect the system’s heating

and cooling equipment.

• Maintain at least the minimum airflow necessary to keep

heating and cooling equipment running efficiently.

IS A ZONING SYSTEM RIGHT FOR THIS JOB?

When designing a zoning system, it is important to keep in mind

what a zoning system can and can not do. A zoning system is only

part of a complete heating and cooling system. A properly selected

heating and cooling system has a limited heating and cooling

capacity. A zoning system may or may not increase the effective

capacity. This depends on whether the system is being designed

for comfort (no increase) or energy savings (some increase in

overall effective system capacity).

A zoning system reduces the effective size of the air distribution

system as dampers are adjusted and closed to meet the needs of the

zone. The primary challenge when designing a zoning system is to

make sure that the air distribution system cannot become so

effectively small that the reduction in airflow causes one of the

following problems:

• Air noise or draft becomes excessive.

• The heating or cooling equipment is shut down because

temperature limits are exceeded.

• The life of the equipment is reduced because of stresses related

to excess temperatures.

The addition of a zoning system will not correct undersized

duct problems. A zoning system will compensate for oversized

ducts, but might make a bad situation worse in the case of

undersized ducts. There are many ways to make a marginal duct

system perform better. Most of these approaches involve changing

ducts, registers, and/or heating or cooling equipment.

DESIGNING A ZONE PERFECT PLUS INSTALLATION

The main objective when designing a zoning system is to maintain

at least minimum airflow through the system when only one zone

requires conditioning, yet still provide sufficient airflow when all

zones require conditioning. The tasks described below provide

step-by-step instructions for designing an effective zoning system.

These tasks are grouped in the following phases:

Assigning Zones

Task 1–Assess the goals for comfort and energy savings.

Task 2–Conduct a site survey and make preliminary zone assign-

ments.

Zoning Design Guide

ZONE PERFECT PLUS

Cancels: AP17–2 AP17–5

8-00

—1—

Loading...

Loading...