2002 Buell X1: Engine 3-39

HOME

CLEANING AND INSPECTION

1. Clean all parts in cleaning solvent. Blow out holes and oil

passages with compressed air.

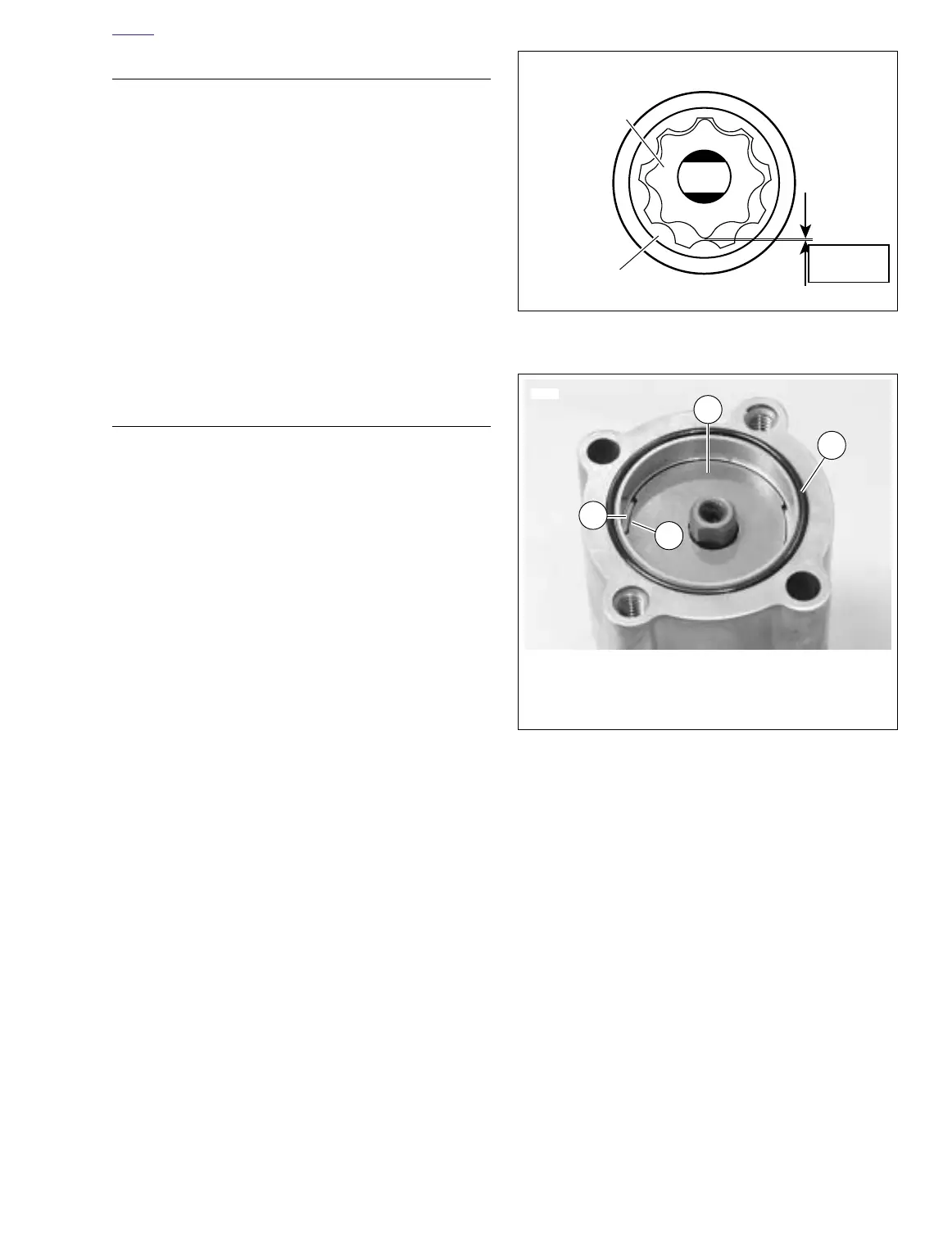

2. See Figure 3-56. Inspect both gerotor sets for wear.

a. Mesh pieces of each set together as shown.

b. Use a feeler gauge to determine clearance.

c. The SERVICE WEAR LIMIT between gerotors is

0.004 in. (0.102 mm). Replace gerotors as a set if

clearance exceeds this dimension.

d. Measure thickness of feed gerotors with a microme-

ter. Replace gerotors as a set if they are not the

same thickness.

3. See Figure 3-55. Check gear shaft (11) teeth for damage

or wear. Replace if necessary.

ASSEMBLY/INSTALLATION

NOTE

Liberally coat all moving parts with clean engine oil to ensure

easy assembly and smooth operation at start-up.

1. See Figure 3-55. Install gear shaft (11) through body

(12). Position thrust washer (15) over end of shaft. Install

new

retaining ring (16) into groove in shaft.

2. Insert inner gerotor of the gerotor scavenge set (9) over

gear shaft.

3. Place outer gerotor over inner gerotor to complete scav-

enge set (9).

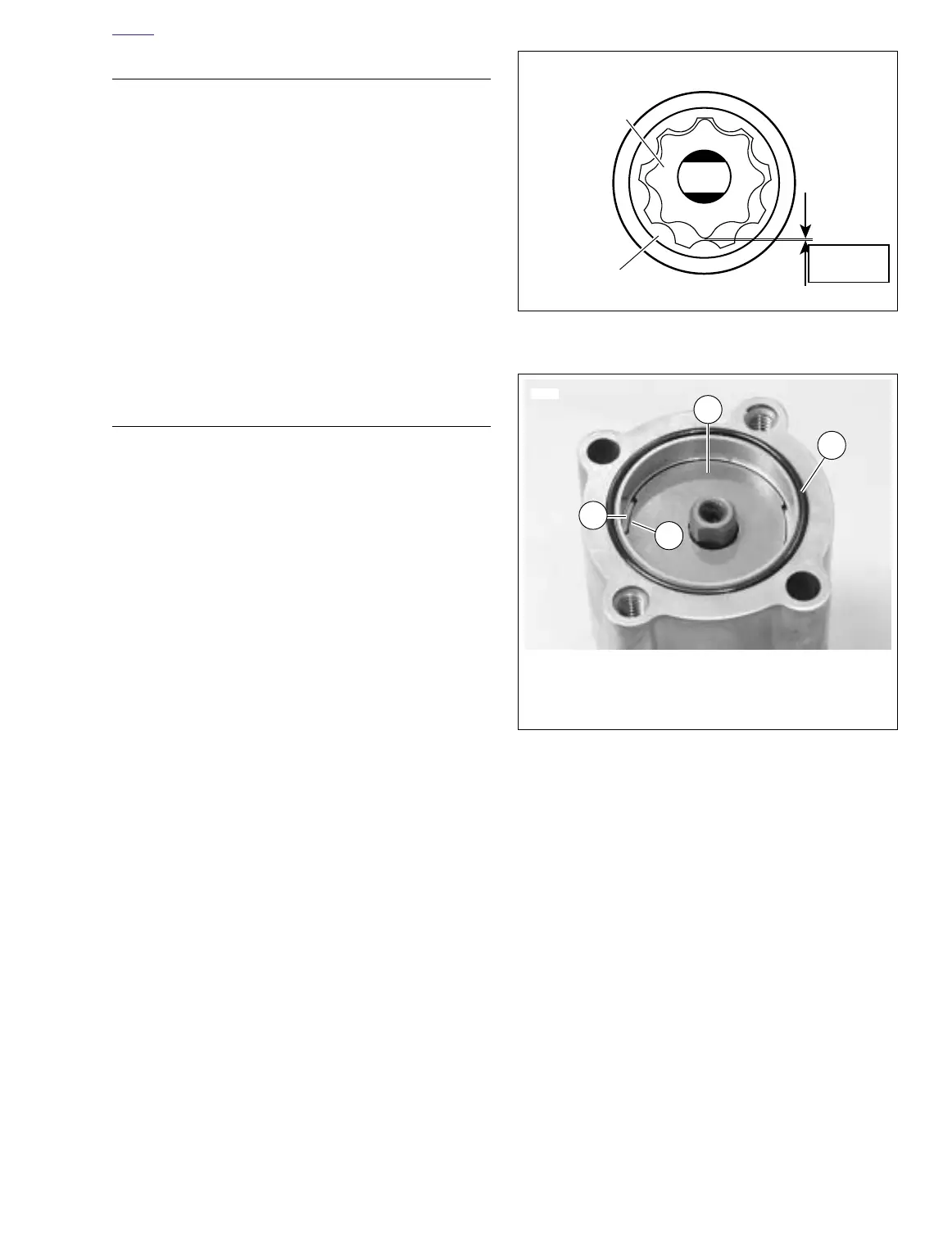

4. See Figure 3-57. Install gerotor separator plate (1) by lin-

ing up slots (2) on perimeter with tabs (3) inside oil pump

body.

5. Install a

new

O-ring (4) into groove in pump body.

6. See Figure 3-55. Place gerotor feed set (7) over gear

shaft (11).

7. Place cover onto pump body. Install cover TORX screws

(2). Tighten screws to 70-80

in-lbs

(8-9 Nm).

8. Place

new

mounting gasket (10) in position.

NOTE

Use

new

hose clamps. If fittings were removed, use

TEFLON

®

PIPE SEALANT or HYLOMAR

®

on fitting threads.

9. See Figure 3-54. Attach return hose connection (4).

10. Secure pump to crankcase with mounting screws (1) and

washers. Tighten screws to 125-150

in-lbs

(14-17 Nm).

11. Attach feed hose (3) and oil filter hose connection (5).

12. Attach clamp (6) and canister to hose.

13. Check engine oil level. Add oil to correct level if needed.

See 1.6 ENGINE LUBRICATION SYSTEM.

Figure 3-56. Gerotor Wear Limits

Figure 3-57. Separator Plate Slots

Inner Gerotor

b0097x3x

Outer Gerotor

Wear

Limit

0.004 in.

(0.102 mm)

1

6620

2

3

1. Gerotor Separator Plate

2. Slot on Separator Plate

3. Tab on Oil Pump Body

4. O-Ring

4

Loading...

Loading...