25

Table 7: Pilot Burner Location

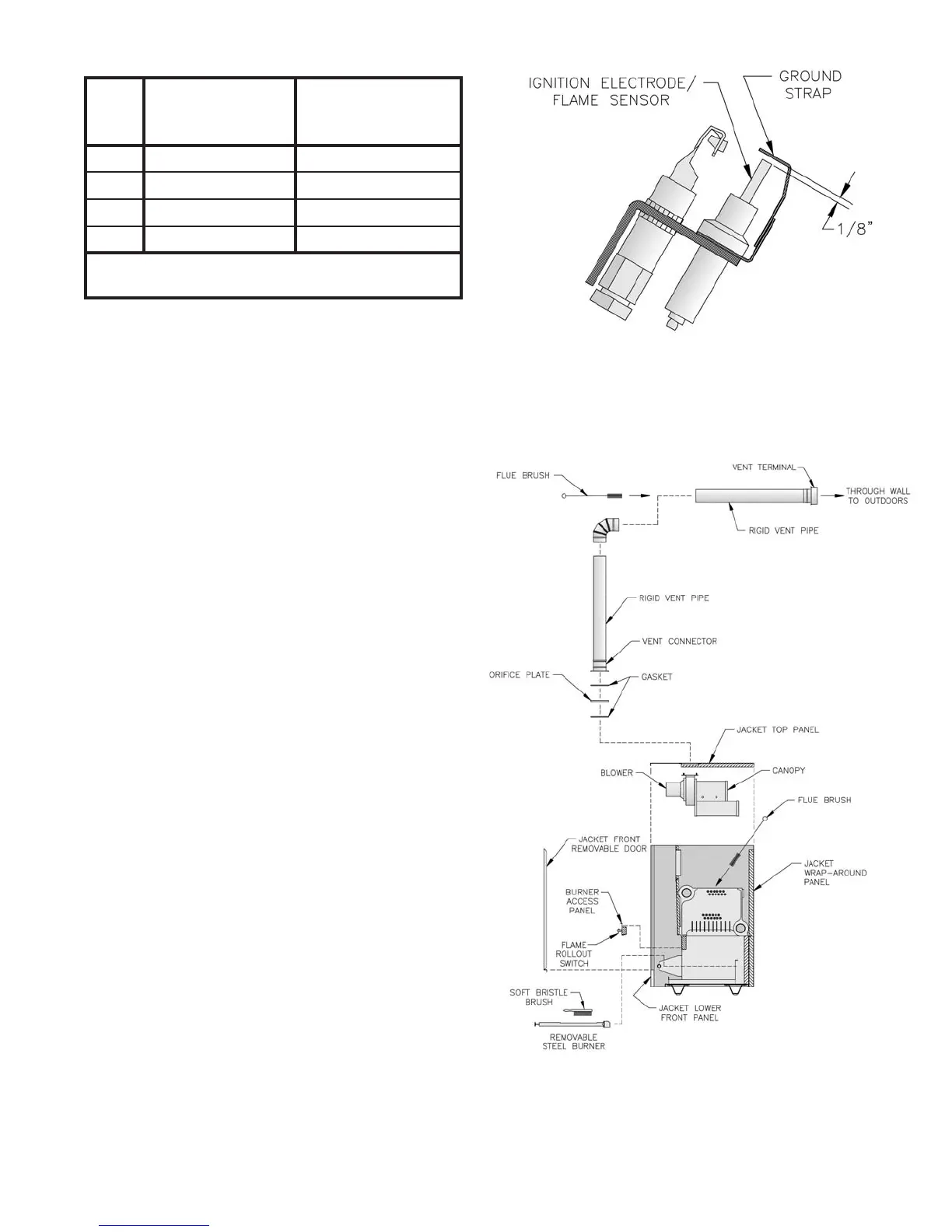

Figure 18: Spark Gap Setting

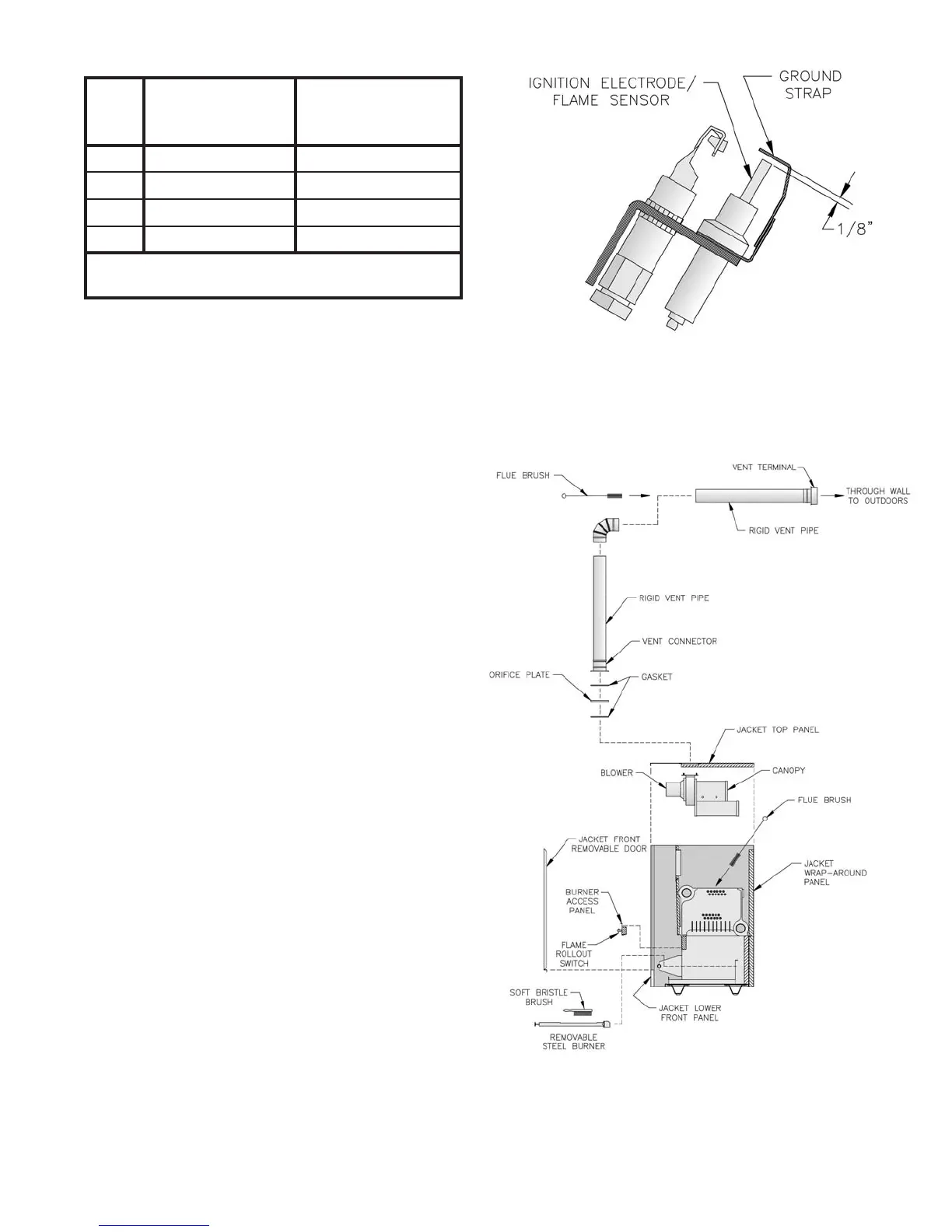

Figure 19: Flueway Cleaning

H. Removal or replacement of pilot assembly or

pilot assembly parts. If pilot assembly, sensor or

pilot orifi ce need replacing, remove main burner

with pilot using procedure described in

Paragraph F.1.

1. To replace orifi ce.

a. Disconnect pilot tubing. Pilot orifi ces

screw into Pilot Burner. Replace with

Honeywell 388146NE (Natural Gas) or

Honeywell 388146KP (LP/Propane).

b. Reconnect pilot tubing and check for

leaks.

2. To adjust or check spark gap between

electrode and hood on Honeywell Q348A

intermittent pilot. See Figure 18.

a. Use round wire gauge to check spark

gap.

b. Spark gap should be 1/8 inch for

optimum performance.

3. To replace complete pilot assembly.

a. Remove two machine screws holding

pilot burner to pilot bracket.

b. Disconnect pilot tubing.

c. Disconnect all other leads to pilot.

d. Select pilot assembly with identical

model number, reconnect leads and pilot

tubing. Resecure to pilot bracket.

4. Reinstall main burner following procedure

described in Paragraph F.

I. Lubrication. There are no parts requiring

lubrication by service technician or owner.

Circulator bearings are water lubricated. Blower

motor bearings are factory sealed.

J. Procedure for measuring blower inlet

pressure. See Figure 20.

1. With boiler off, remove hose at pressure

switch.

2. With tee connect water manometer as shown

with additional tubing.

relioB

ledoM

htiwrenruBniaM

*tekcarBtoliP°06

detacoLrenruBtoliP

niaMneewteB

*srenruB

VP3021 2&1

VP4022 3&2

VP5023 4&3

VP6024 5&4

morfdeweivsathgirottfelderebmunsrenrubniaM*

.reliobfotnorf

Loading...

Loading...