Installation | 5

0870145123_SB0050-1400D0_D2_A0000_IM_en 7 / 24

• Low vibration (V

eff

< 2.8mm/s)

If the storage time exceeds 4 years:

• Replace and relubricate the bearings with specific grease type: ESSO Unirex N3

• Clean and relubricate the bearing intermediate place

• Replace and relubricate the shaft seals

5 Installation

5.1 Installation Conditions

• Make sure that the environment of the machine is not potentially explosive.

• Make sure that the ambient conditions comply with the Technical Data [►17].

• Make sure that the environmental conditions comply with the protection class of the

motor.

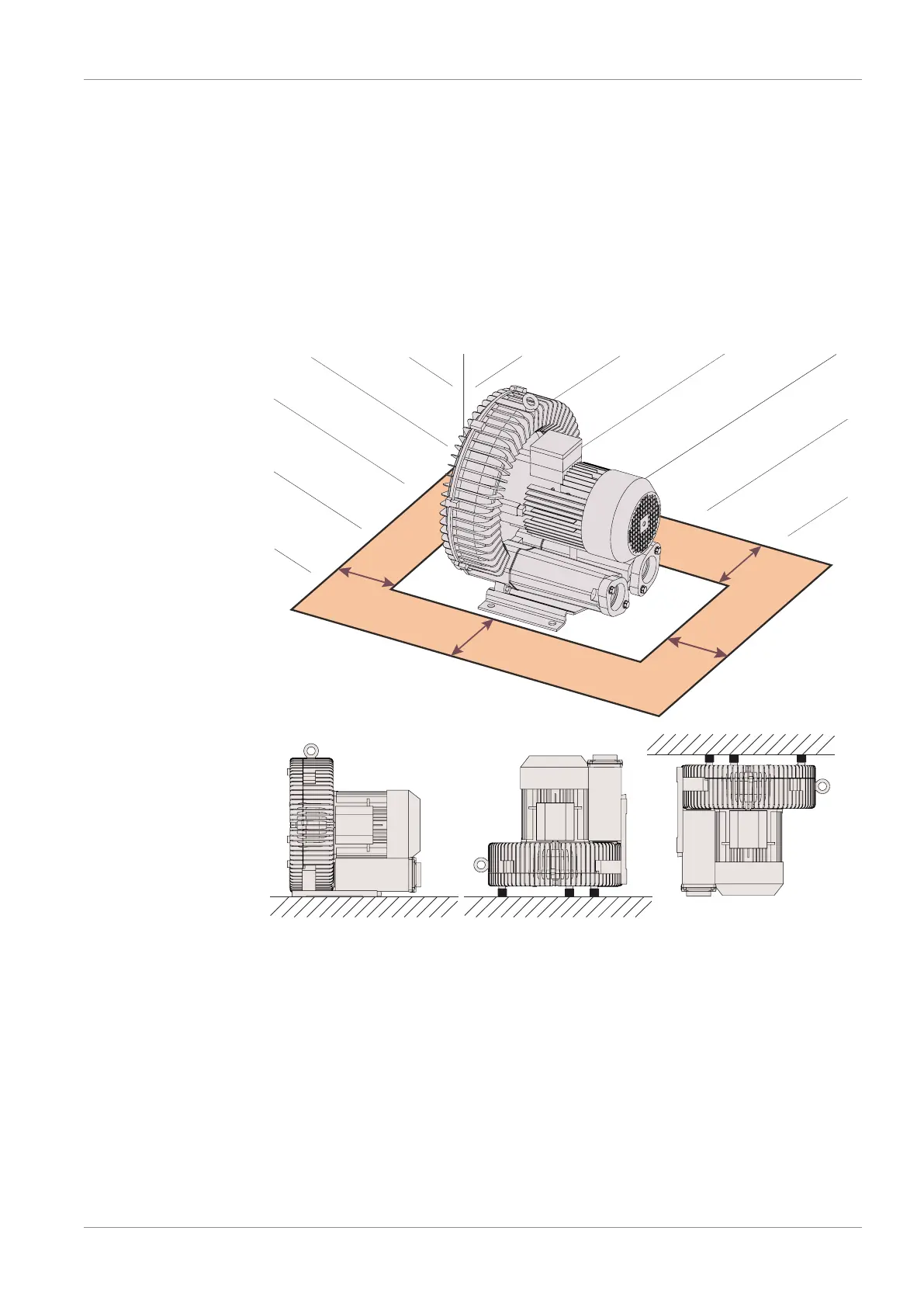

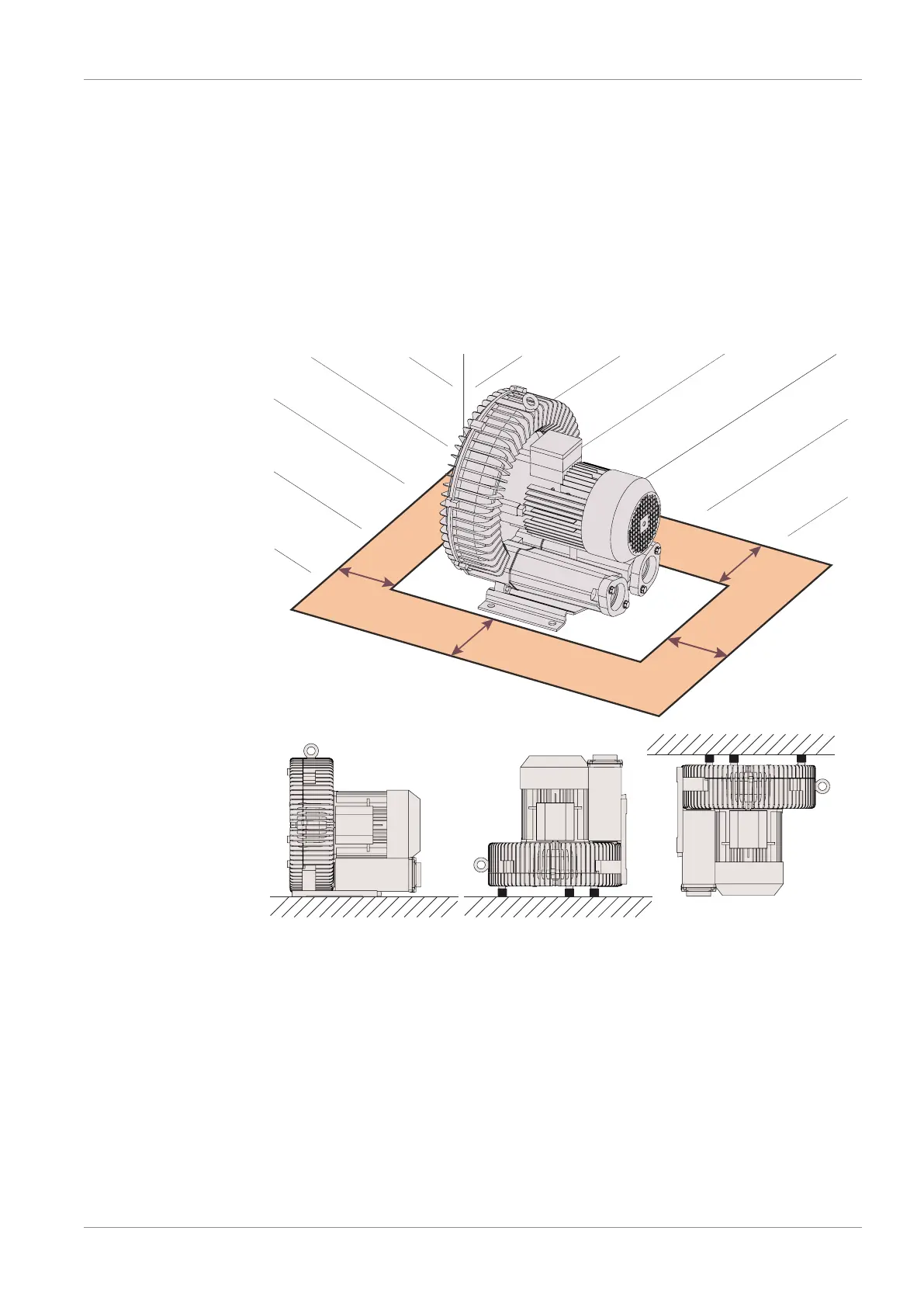

• Make sure that the installation space or location is vented such that sufficient cooling

of the machine is provided.

• Make sure that cooling air inlets and outlets are not covered or obstructed and that

the cooling air flow is not affected adversely in any other way.

• Make sure that the machine is placed or mounted horizontally/vertically, with a max-

imum deviation of 1° in any direction.

• Make sure that the machine is placed or mounted horizontally on a flat surface.

• Make sure that all provided covers, guards, hoods, etc. are mounted.

Loading...

Loading...