- 6 -

and #10 wing nuts secure the two remaining coil clamps, tightening the wing nuts only enough

to hold the hardware in place. Coil adjustments will be made later.

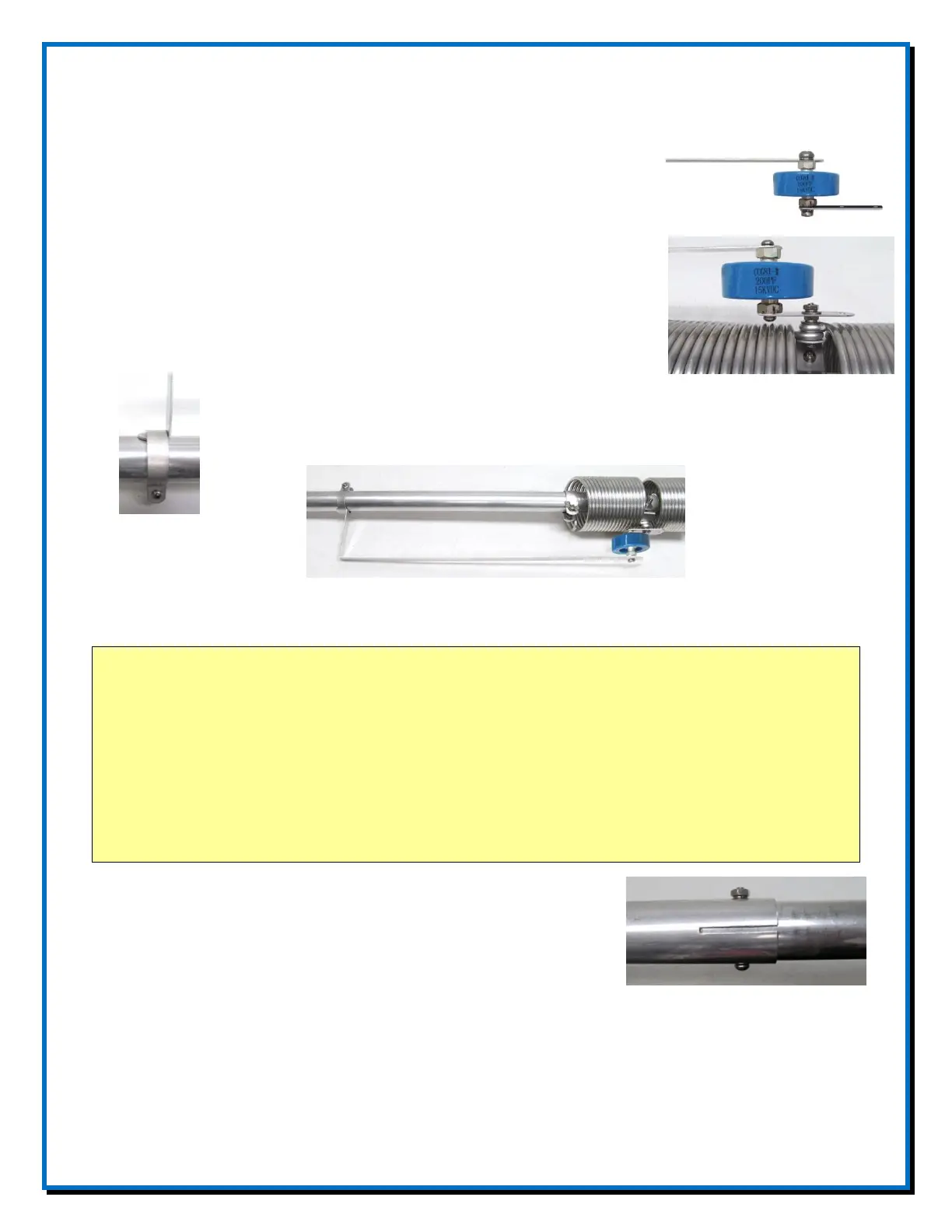

5. Install the capacitor bracket (E) on the capacitor assembly (D) using

the hardware already on the capacitor.

6. Position capacitor assembly (D) over the threaded end of the bolt

protruding from the center coil clamp on the 80/40 meter coil

assembly (C). Make sure that the capacitor bracket (E) runs along

side the lower (80 meter) coil of the 80/40 meter coil assembly (C).

Fasten the capacitor assembly (D) to the 80/40 meter coil assembly

(C) using a #10 flat washer, #10 lock washer and a #10 hex nut.

Using the large non-adjustable clamp, fasten the end of capacitor bracket (E) firmly

against base section (B) and secure it with a #8 x 1" bolt, #8 lock washer and a #8

hex nut.

NOTE: IN THE FOLLOWING STEPS TUBING SECTIONS G THROUGH M WILL BE

ASSEMBLED AS A UNIT FOR LATER PLACEMENT ON THE BASE SECTION.

Note: Jet-Lube

™

SS-30 Anti-Oxidant should be used between all antenna element sections.

Jet-Lube

™

SS-30 is an electrical joint compound to affect a substantial electrical

connection between metal parts such as telescoping aluminum tubing or other antenna

pieces. It ensures high conductivity at all voltage levels by displacing moisture and

preventing corrosion or oxidation.

Jet-Lube

™

SS-30 should also be used on all coil clamps, element clamps, bolts and

stainless steel threaded hardware to provide good electrical contact, prevent galling,

allow easier disassembly and to ensure proper tightening.

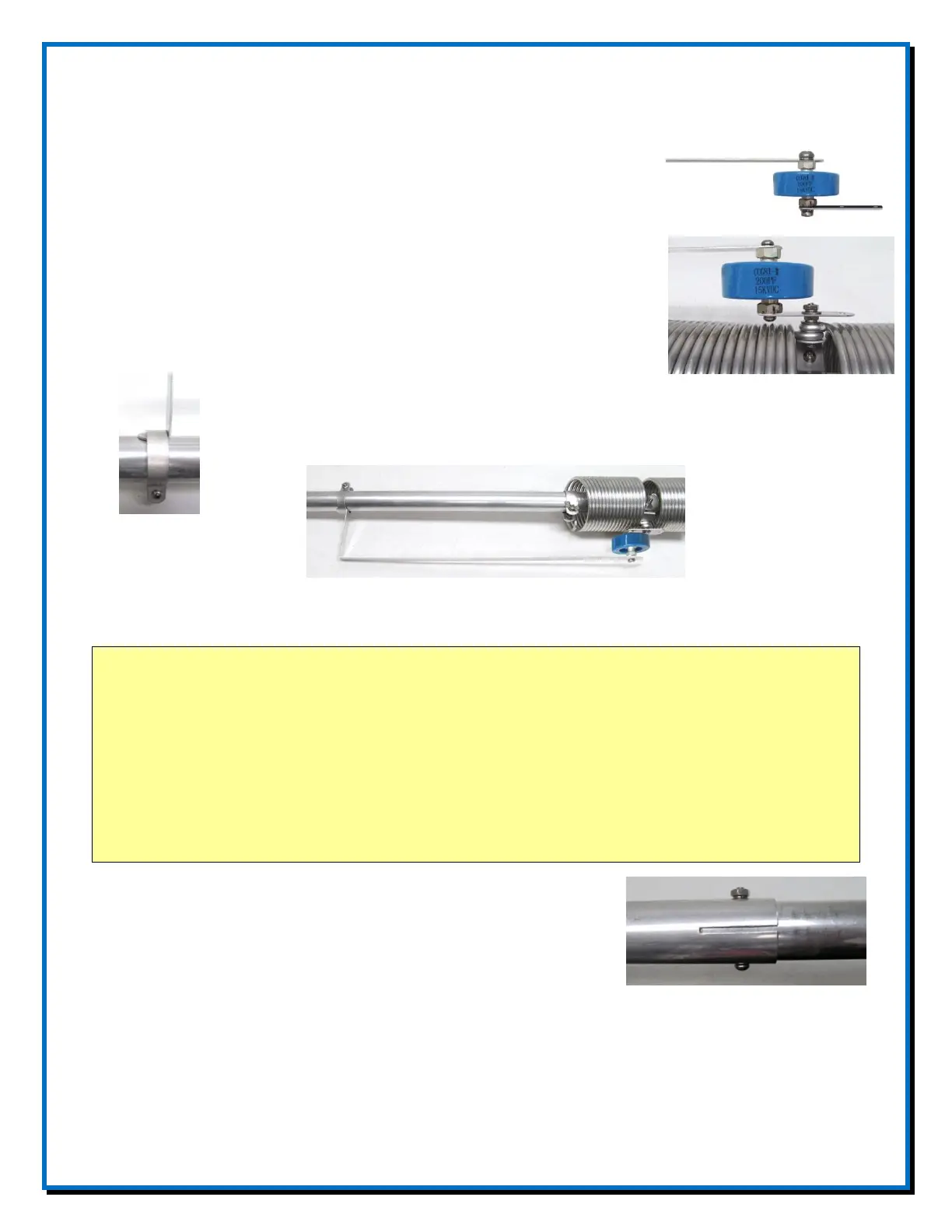

7. Insert the un-slotted end of tube (H) into the slotted end of tube

(G), align the four holes, and pass a #8 x 1 1/2" bolt through

both tubes. Secure it with a #8 lock washer and #8 hex nut and

tighten snugly.

Typical screw/lock washer, hex nut installation between tubes H through L.

Steps 7 through 10

Do not over tighten which may deform or damage the tubing.

8. Insert the un-slotted end of tube (I) into the slotted end of tube (H) and proceed as in step 9,

using a #8 x 1 1/4" bolt, #8 lock washer and #8 hex nut.

Loading...

Loading...